Composite desulphurization method and device for high-sulfur coal

A desulfurization device and coal technology, applied in the field of coal desulfurization, can solve the problems of high cost, large amount of chemical reagents, long microwave irradiation time, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

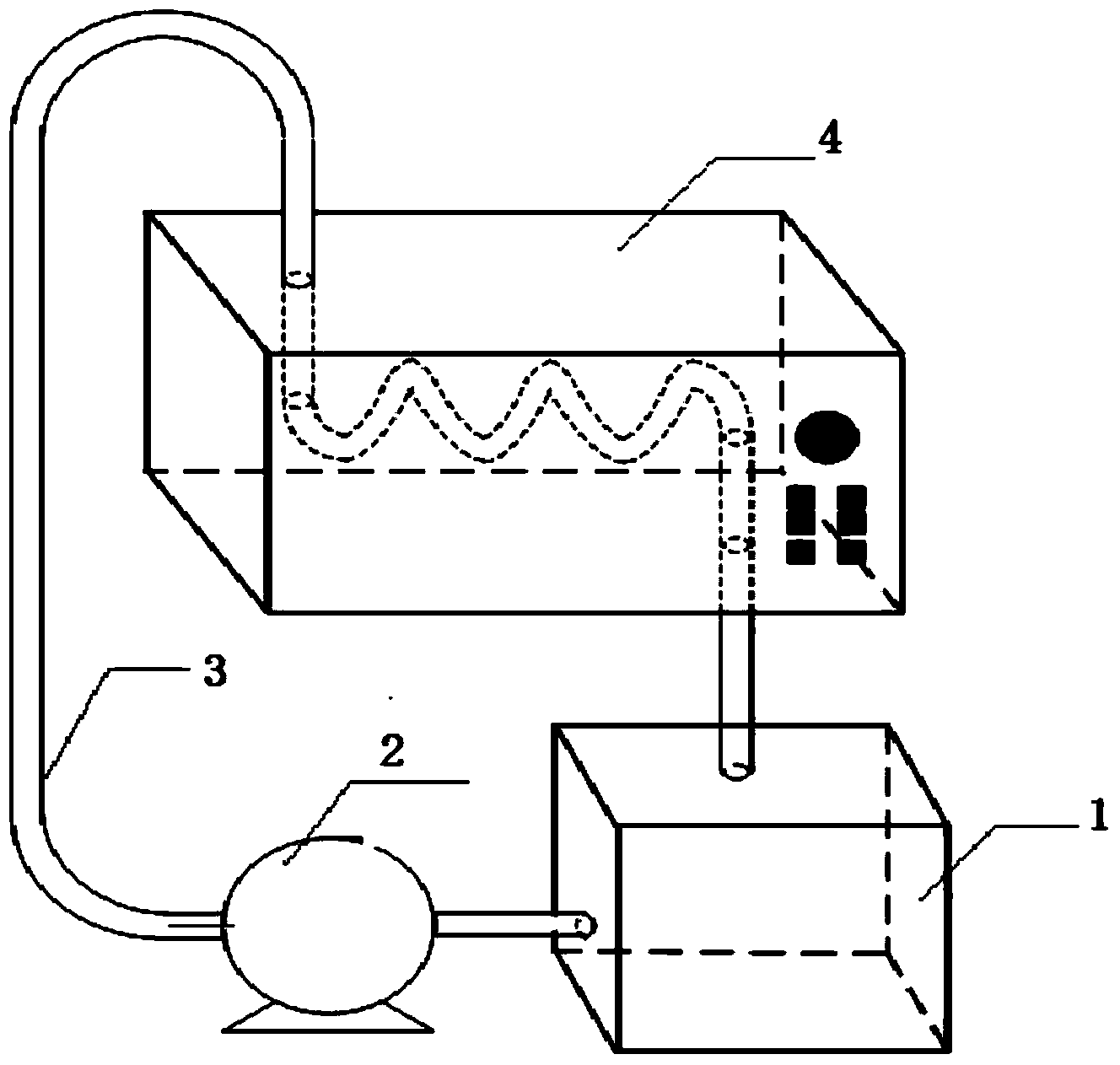

[0023] The high-sulfur coal composite desulfurization device described in this embodiment is as follows: figure 1 As shown, it includes a reactor 1, a circulation pump 2, a circulation heating pipe 3 and a microwave heater 4. The liquid outlet of the reactor 1 is connected with the liquid inlet of the circulation pump 2 through a pipe fitting, and the outlet of the circulation pump 2 The liquid port is connected to one end of the circulation heating pipe 3, and the other end of the circulation heating pipe passes through the heating chamber of the microwave heater 4 and is connected to the liquid inlet of the reactor. The reactor is a cube-shaped container, and the part of the circulating heating pipe located in the heating chamber of the microwave heater is a wave-shaped curved pipe.

[0024] Using the above-mentioned high-sulfur coal compound desulfurization device to carry out the method for compound desulfurization of high-sulfur coal, the process steps are as follows:

...

Embodiment 2

[0030] The difference between the high-sulfur coal compound desulfurization device described in this example and the device described in Example 1 is that the reactor is a cylindrical container.

[0031] Using the above-mentioned high-sulfur coal compound desulfurization device to carry out the method for compound desulfurization of high-sulfur coal, the process steps are as follows:

[0032] ①Put 100g of high-sulfur coal (3.2% sulfur by mass) pellets with a particle size of 0.5mm into the reactor, and add them to the reactor at a mass ratio of high-sulfur coal pellets to water of 1:0.8 water, then open the circulation pump 2 and microwave heater 4 in the high-sulfur coal composite desulfurization device, keep the flow velocity of the circulation pump as 0.01m / s, the frequency of microwave heater 4 is 2.45GHz, and the power is 1000W, so that the coal The water mixture liquid is preheated for 15 minutes in a circulating flow state, and the microwave heater 4 is turned off after...

Embodiment 3

[0037] The difference between the high-sulfur coal compound desulfurization device described in this example and the device described in Example 1 is that the reactor is a spherical container.

[0038] Using the above-mentioned high-sulfur coal compound desulfurization device to carry out the method for compound desulfurization of high-sulfur coal, the process steps are as follows:

[0039]①Put 100g of high-sulfur coal (3.2% sulfur by mass) pellets with a particle size of 0.3mm into the reactor, and add them to the reactor at a mass ratio of high-sulfur coal pellets to water of 1:1.5 water, and then open the circulating pump 2 and the microwave heater 4 in the high-sulfur coal composite desulfurization device, keep the flow velocity of the circulating pump as 0.04m / s, the frequency of the microwave heater 4 is 2.45GHz, and the power is 1200W, so that the coal The water mixture liquid is preheated for 15 minutes in a circulating flow state, and the microwave heater 4 is turned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com