Novel plunger applicable to sand-producing fluid-producing gas well plunger lifting techniques

A plunger, liquid gas technology, applied in the field of new plunger, can solve problems such as poor operation and sand stuck operation of the plunger, and achieve the effect of improving wear resistance and good sand removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

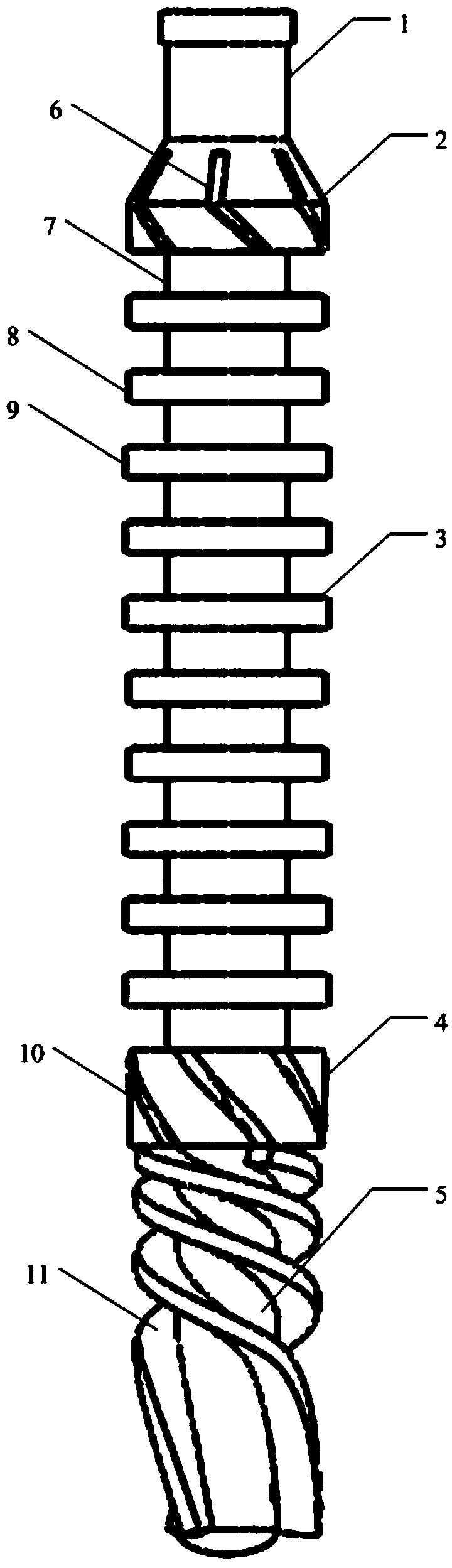

[0016] A new type of plunger suitable for the plunger lifting process of sand producing liquid gas wells, composed of a fishing head 1, a sand scraping structure 2, a sealing structure 3, a sand discharge structure 4 and a helical structure 5 from top to bottom. Located on the top of the plunger, the sand scraping structure is located on the upper part of the plunger, which is a combination of a circular platform and a cylinder, with a sand scraping groove 6 on the surface, and the sealing structure is located in the middle of the plunger, which is a two-layer composite structure. Steel rod, the surface is made of nylon wear-resistant material, the surface has 11 grooves 7, and there is a boss in the middle of every two grooves, and the boss is divided into a small-diameter boss 8 and a large-diameter boss 9, so The outer diameter of the small-diameter boss is the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com