Gob-side entrydriving coal pillar anchor cable through reinforcing method

A technology of anchor cables and coal pillars, which is applied in the direction of earthwork drilling, bolt installation, mining equipment, etc., can solve the problems of high labor intensity of workers, difficulty of roadway support, lack of support means, etc., and achieve outstanding anchoring effect, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The method for cross-penetration reinforcement of coal pillar anchor cables in gob-side roadway of the present invention, its preferred specific implementation mode is:

[0018] Include steps:

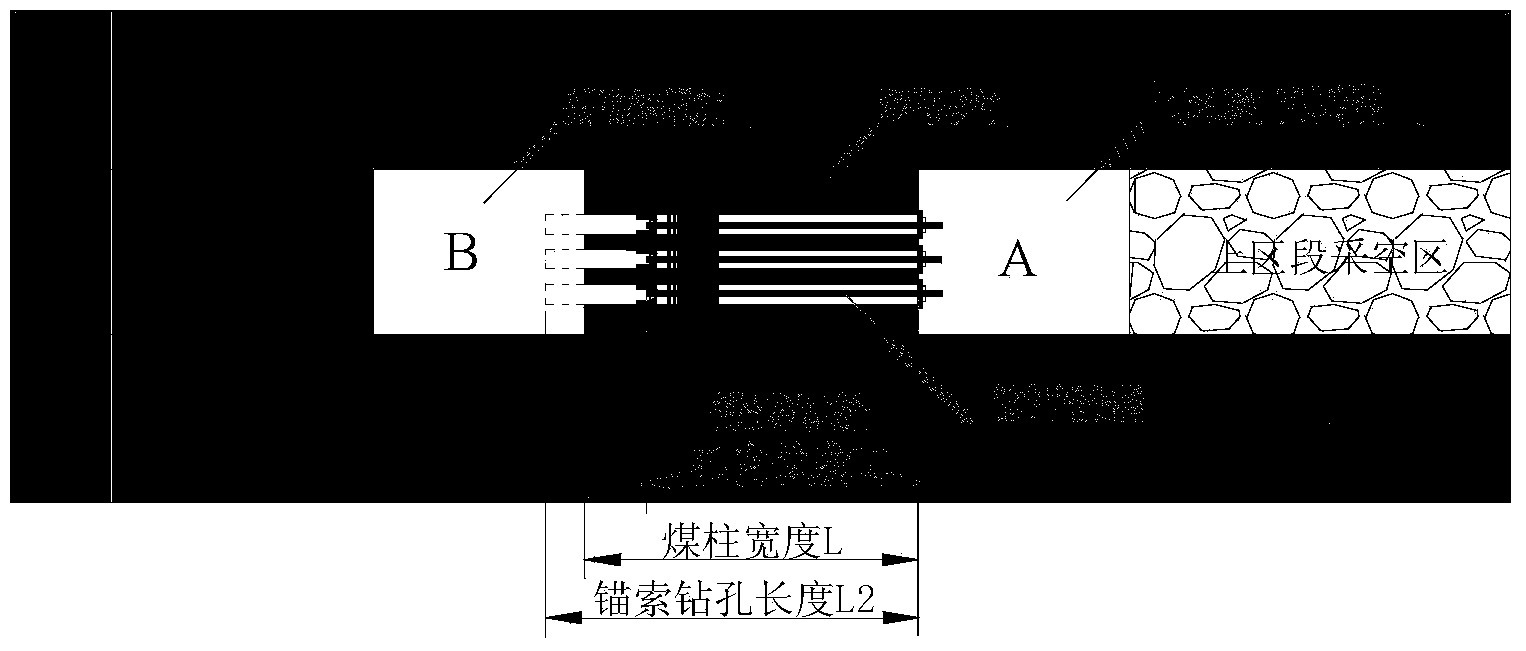

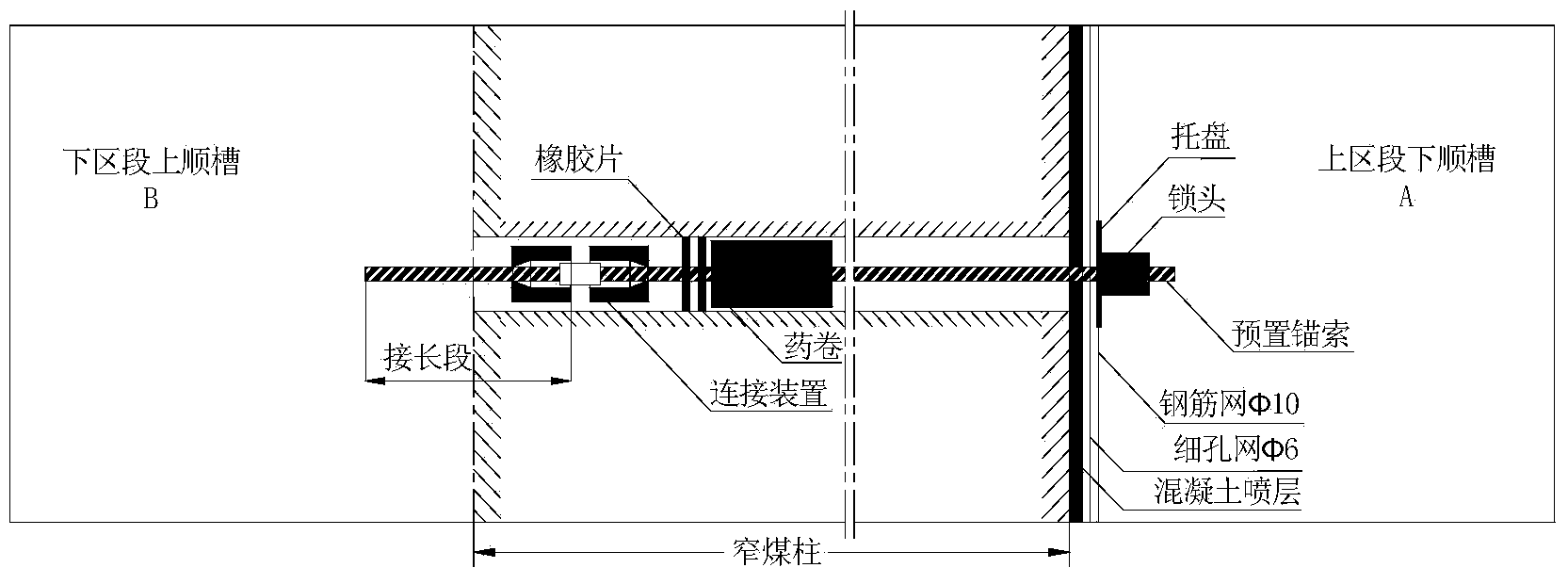

[0019] Such as Figure 1 to Figure 3 As shown, in the upper section, drill holes along the trough to the coal pillar (that is, the narrow coal pillar with a width of 4-6m to be reserved as the "separation wall support body"), and install pre-installed anchors in the borehole cable, and on the coal wall on one side of the drill hole, spray the concrete spraying layer, install the fine mesh, install the steel mesh and the anchor tray, and the lock at the outer end of the anchor cable is fixed on the anchor tray;

[0020] After the tunneling in the lower section is completed, the preset anchor cable in the borehole is lengthened, and finally the same process as above is carried out to complete the anchoring work.

[0021] The reason why the anchor cable lengthening technology is ...

specific Embodiment 1

[0032] Such as figure 1 , figure 2 and image 3 As shown, drilling holes are drilled into the coal pillar in the lower channel (along channel A) in the upper section, and the pre-installed anchor cables are installed. Then, the concrete shotcrete is sprayed on the side of the coal wall of the channel A in sequence, and the fine mesh and steel mesh are installed. And the anchoring tray to complete the anchoring work. After the excavation of the upper channel (along channel B) in the lower section is completed, the preset anchor cables in the coal pillar boreholes are extended, and finally the same process as above is carried out to complete the anchoring work.

[0033] In the present invention, the anchor cable cross-penetration reinforcement technology can be used in gob-side excavation to apply a large anchoring force to the coal pillar, improve the support strength of the coal pillar, and ensure the long-term stability of the coal pillar. In addition, the technology is c...

specific Embodiment 2

[0034] Such as Figure 4 As shown, the telescopic anchor cable is adopted, and the construction method is basically the same as the technical solution in the first embodiment. The preset anchor cable in the coal pillar anchor cable borehole adopts a retractable anchor cable. After the tunneling of the lower section is completed, the anchor cable is lengthened at the end close to the side of the newly excavated roadway B; the anchor cable Opposite gesture Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com