A spiral multi-channel pulse detonation engine

A pulse detonation and helical technology, used in machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of wasting engine space utilization, increasing filling difficulty, and difficulty in increasing detonation frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a helical multi-channel pulse detonation engine.

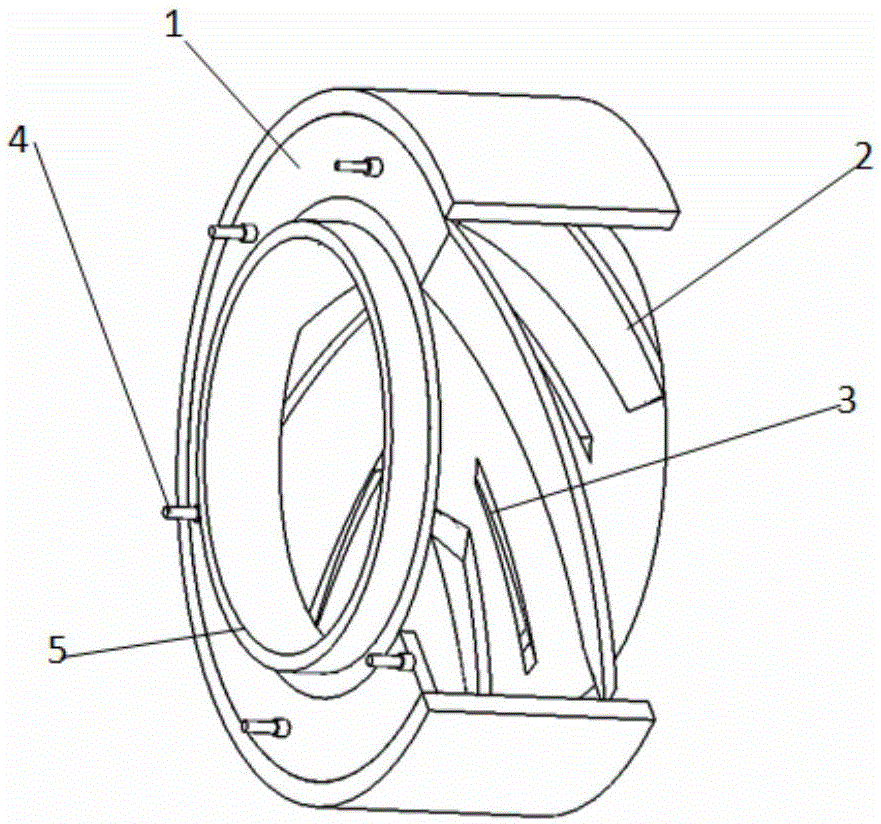

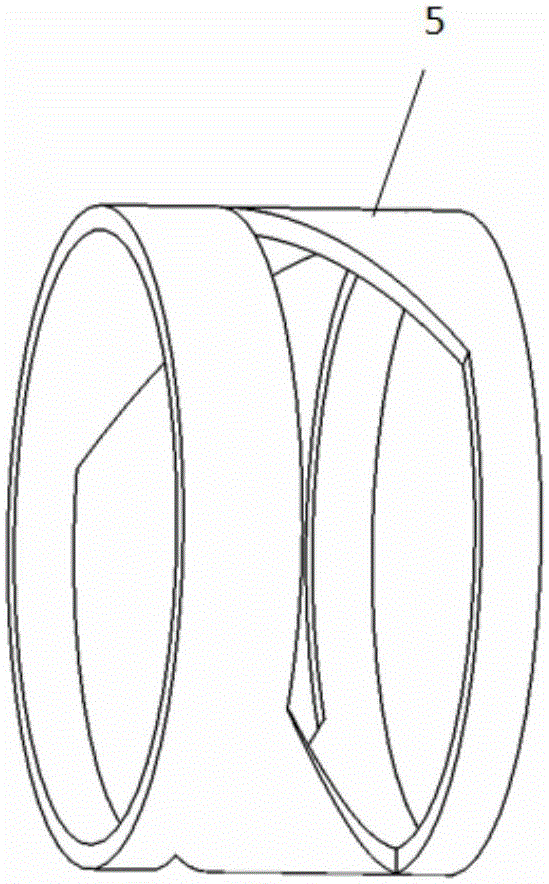

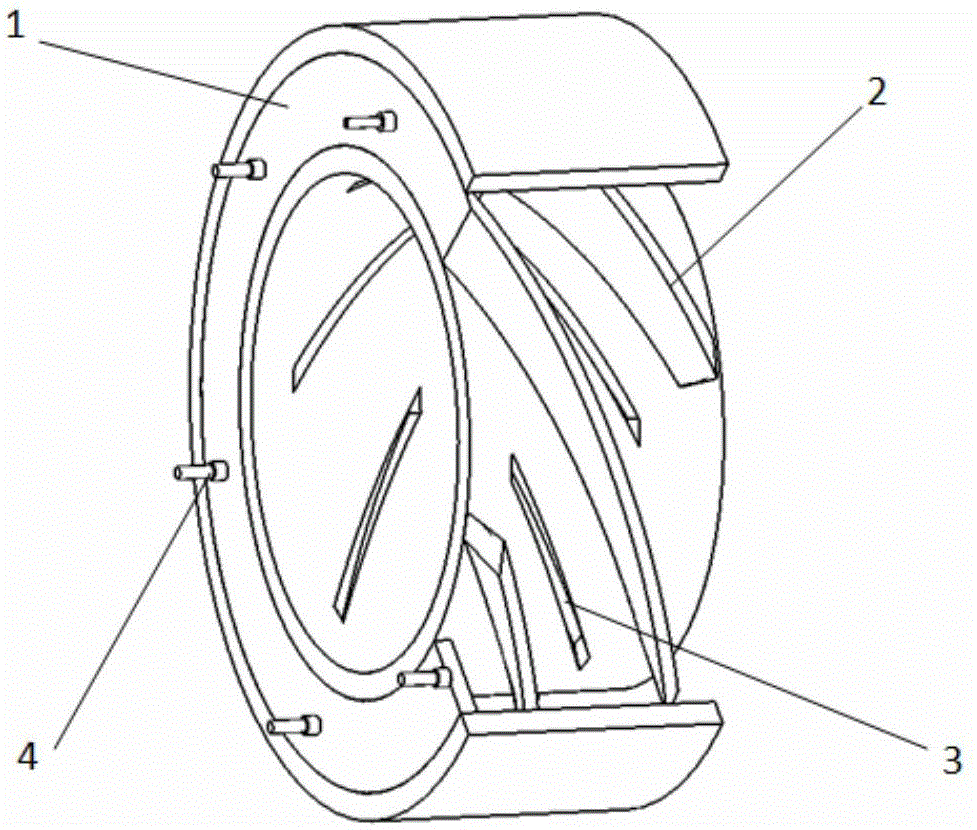

[0020] refer to figure 1 , figure 2 , image 3 , the spiral multi-channel pulse detonation engine of this embodiment is composed of an engine casing 1, a spiral partition 2, an air intake slot 3, a spark plug 4, and an intake rotor 5; the engine casing 1 is a ring structure, and the outer One end of the cavity formed by the ring and the inner ring is sealed, and the spiral partition 2 is fixed on the inner ring wall of the annular cavity. The spiral partition 2 is evenly distributed along the circumference of the inner ring wall to isolate the annular cavity into 2n spiral detonation channels. Where n≥2, there is a spiral air inlet slot 3 on the inner ring wall between the spiral partitions 2, the guide line of the air intake slot 3 has the same parameters as the guide line of the spiral partition 2, and the parameters of the spiral guide line include the pitch , radius, and two helical guide line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com