Backlight module

A technology of backlight module and light source, which is applied in the field of backlight module, can solve the problems of reducing light utilization rate, and achieve the effect of avoiding optical loss, improving luminous efficiency, and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

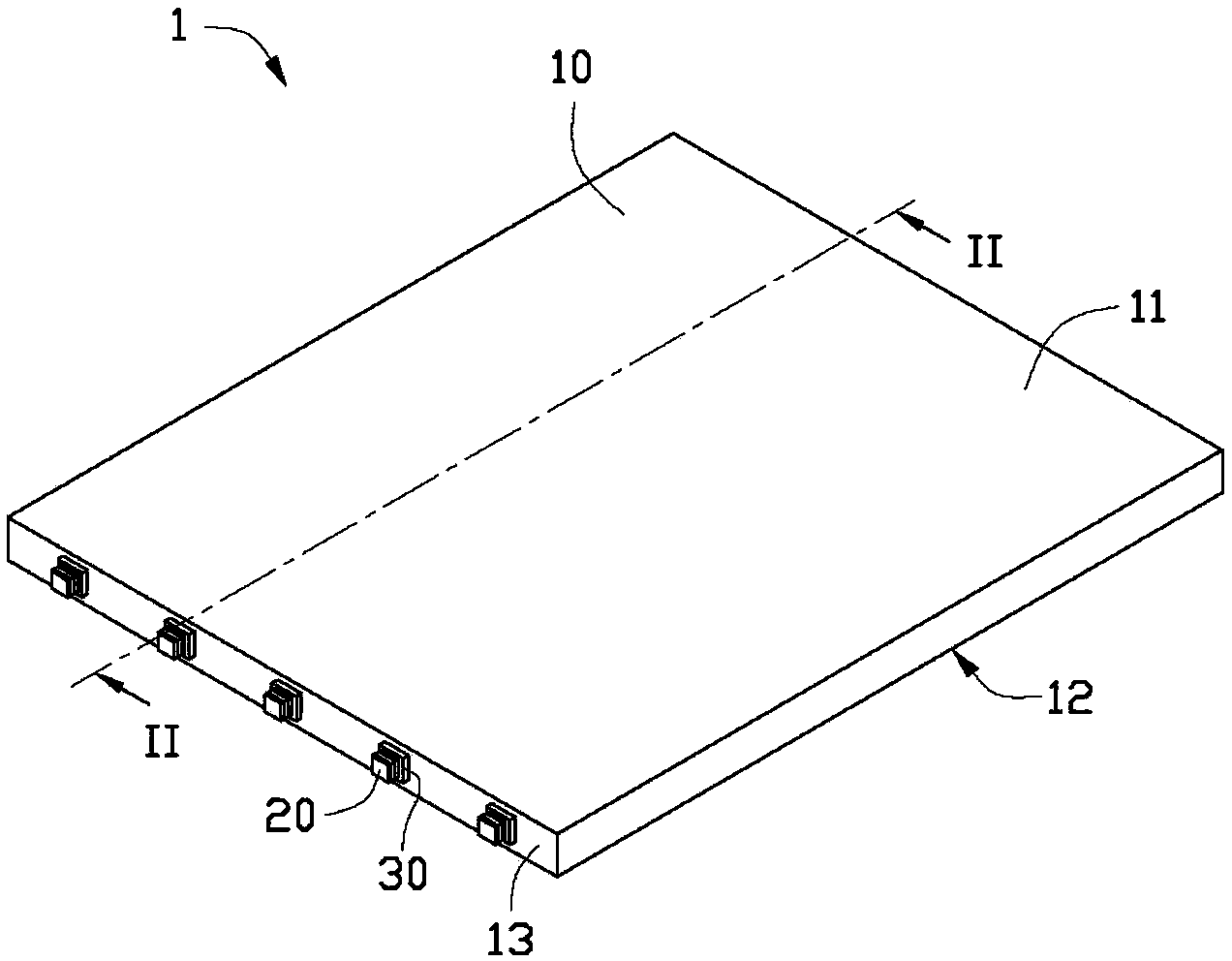

[0013] figure 1 A three-dimensional schematic diagram of a backlight module provided by a preferred embodiment of the present invention. The backlight module 1 includes a light guide plate 10 , a plurality of LED light sources 20 and a transparent glue 30 fixing the plurality of LED light sources 20 to one side of the light guide plate 10 .

[0014] The light guide plate 10 is a thin flat plate, which has an upper surface 11 and a lower surface 12 arranged oppositely and in parallel, and four sides 13 connecting the upper surface 11 and the lower surface 12 . In this embodiment, the side surfaces 13 are perpendicular to the upper surface 11 and the lower surface 12 respectively.

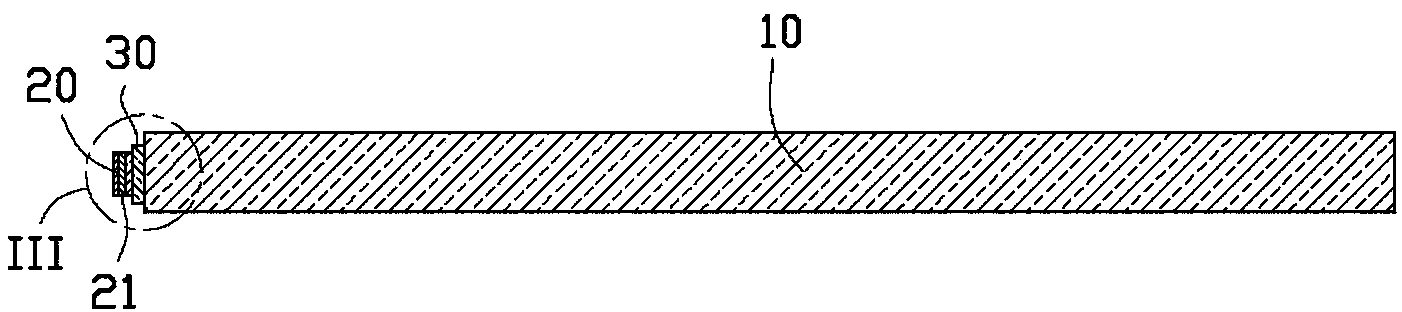

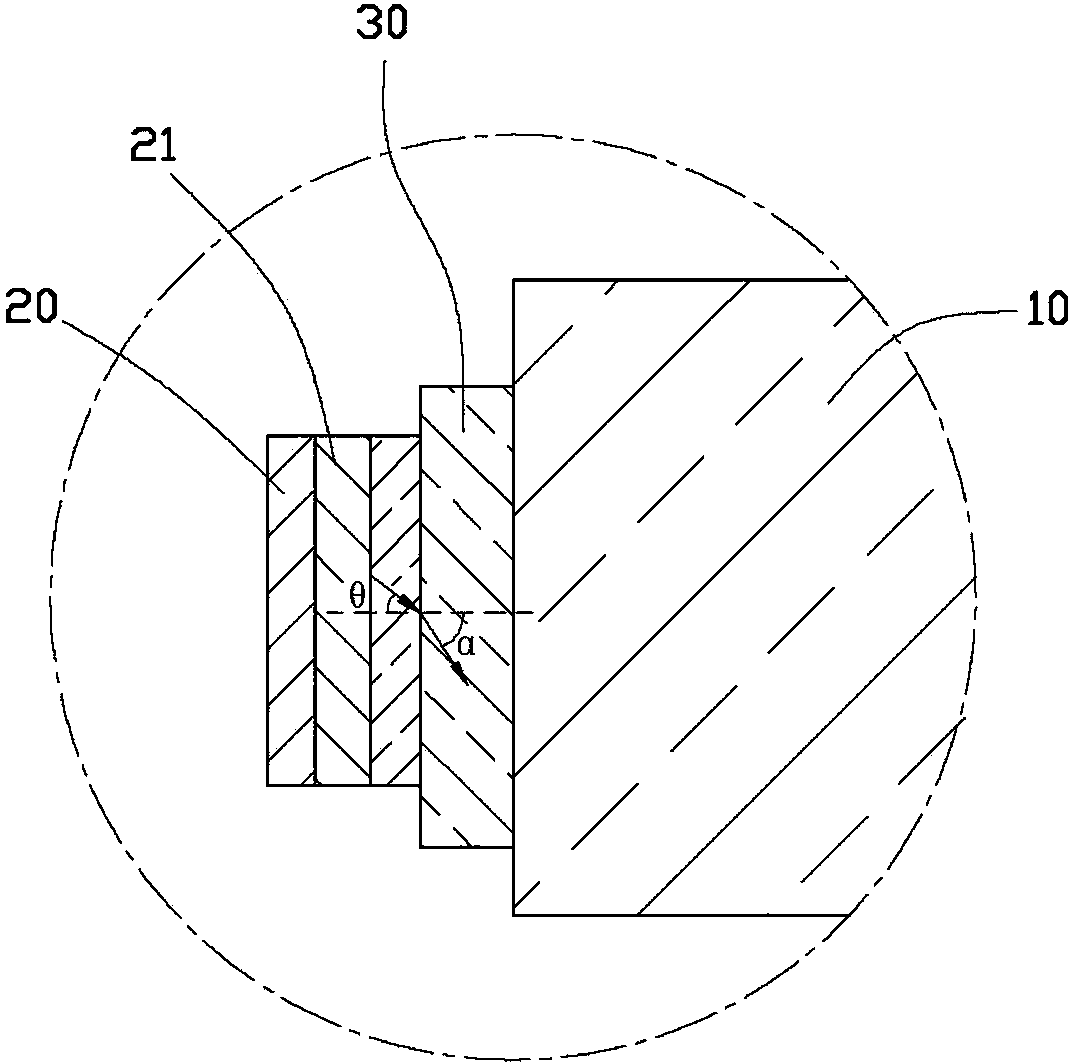

[0015] Please also see figure 2 , the plurality of LED light sources 20 are disposed on one side 13 of the light guide plate 10 , and are all fixed to the same side 13 by glue 30 . The LED light source 20 includes a light-emitting layer 21 inside, and the light emitted by the LED light source 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com