Heating unit fixing device

A technology for fixing devices and heating elements, which is applied in household heating, household heating, heating methods, etc. It can solve the problems that cannot meet the requirements of thermal expansion and extension of heating elements, the installation position of heating elements is not designed, and affect the normal use of heating elements, etc. , to reduce the difficulty of installation and labor intensity, improve the safety of use, reduce the difficulty of molding and the effect of mold manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

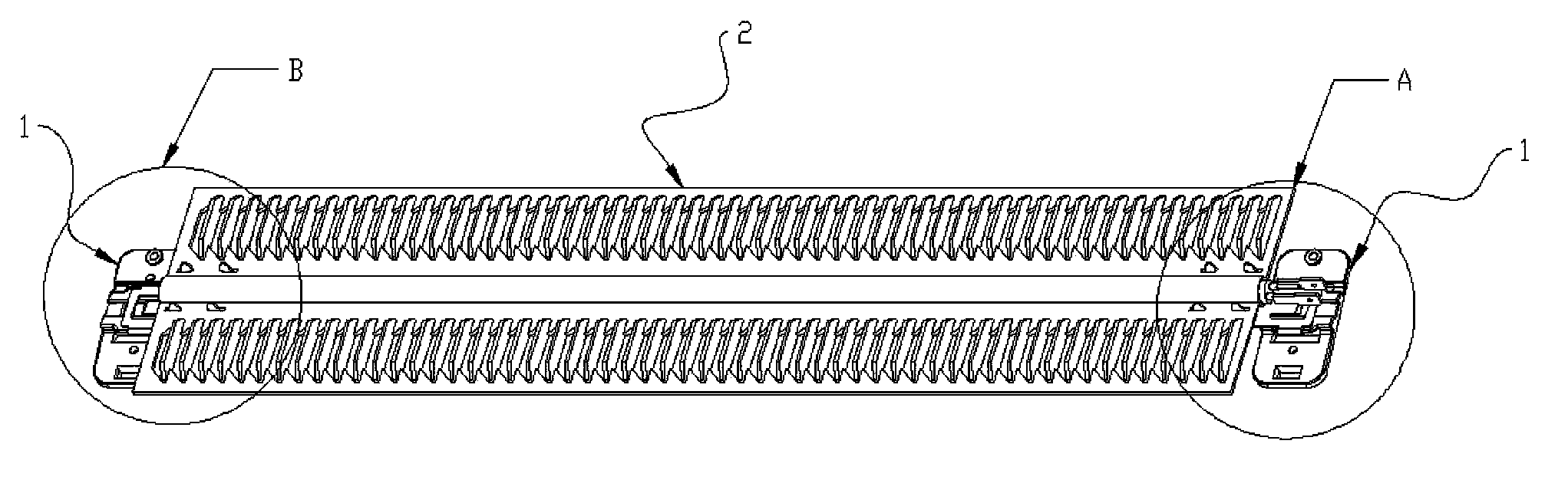

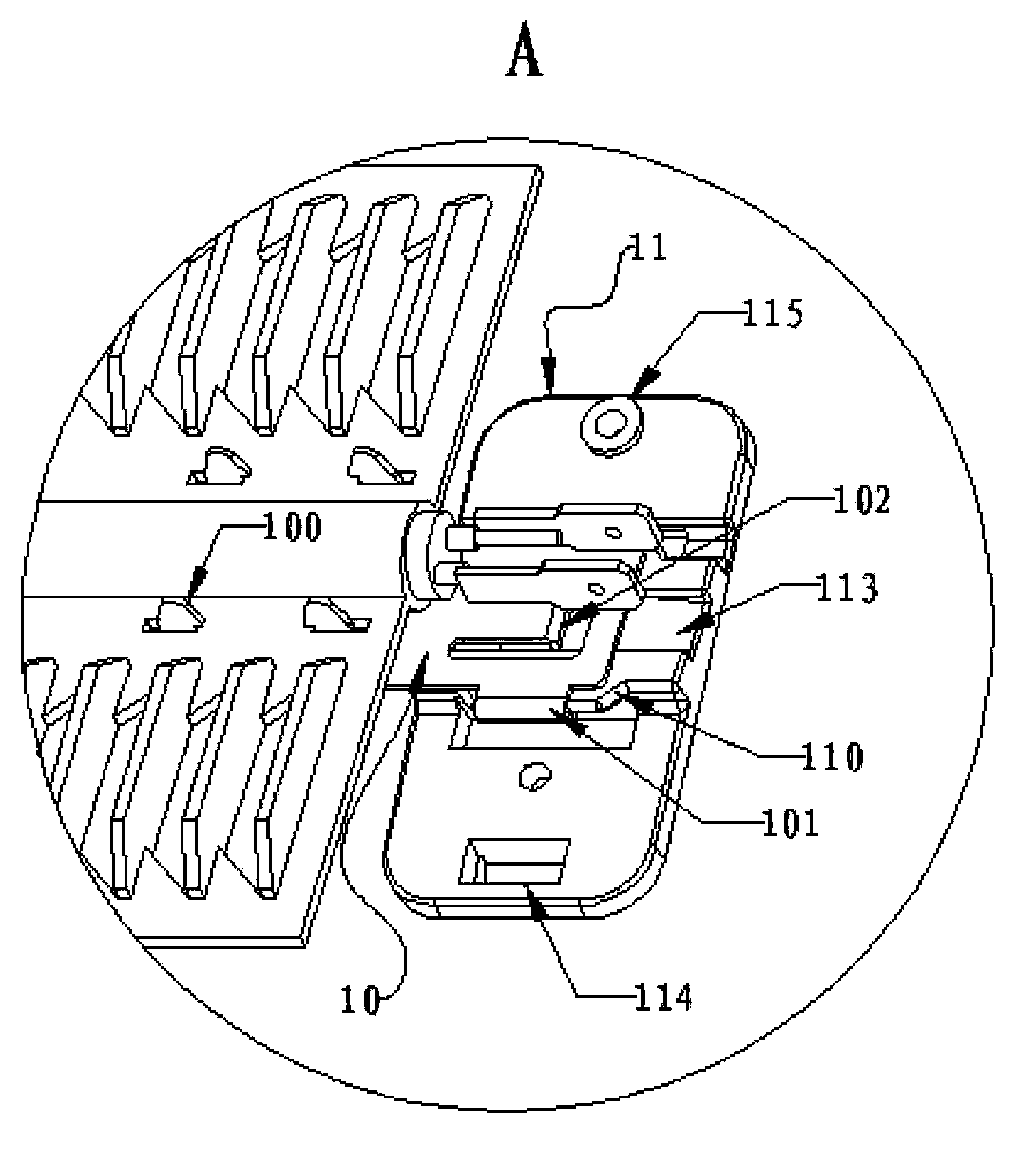

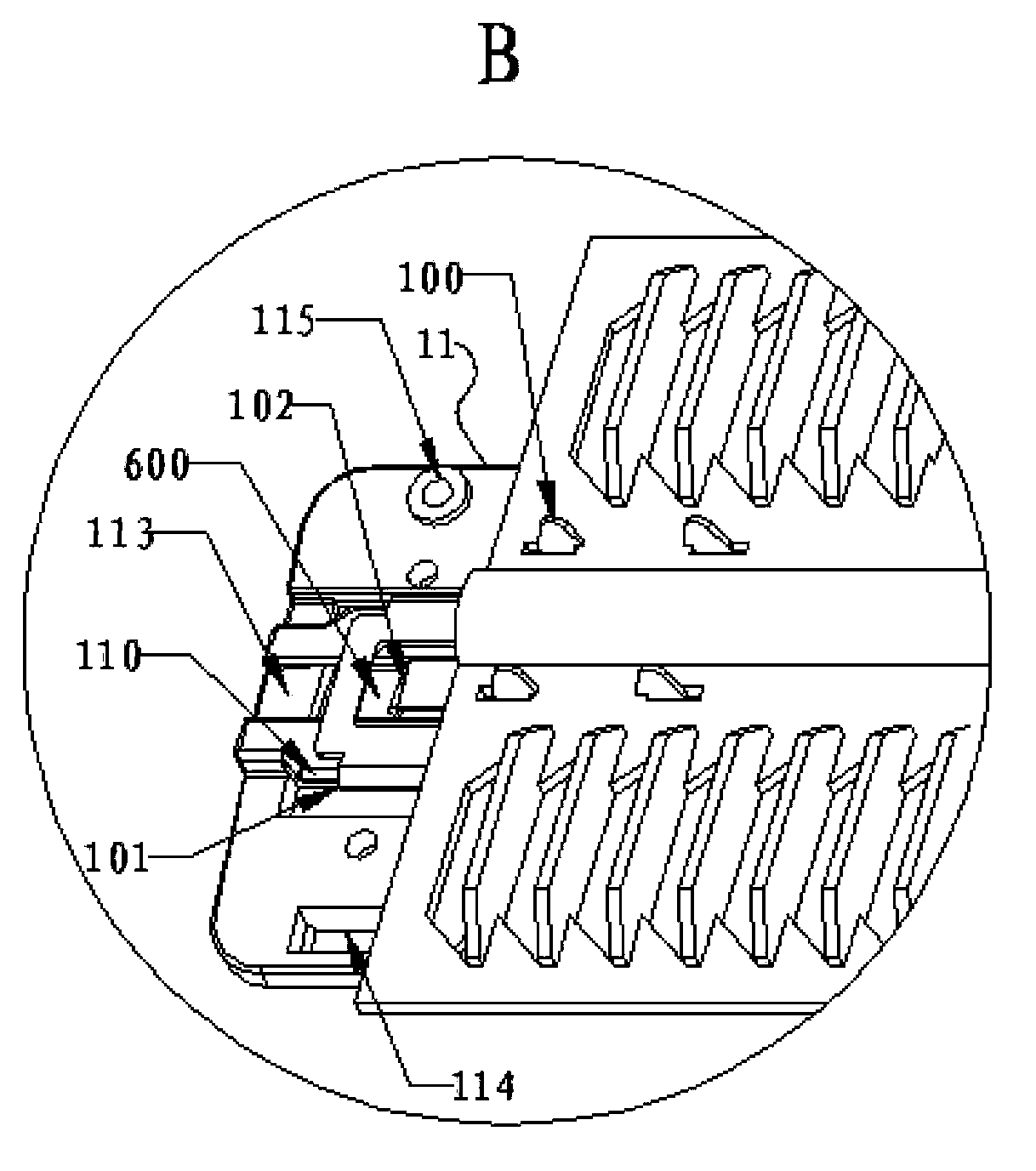

[0042] see Figure 1 to Figure 5 As shown, the heating element fixing device 1 of this embodiment is installed on the left and right ends of the heating element 2, and includes a bracket 10 and a base 11. The bracket 10 is provided with a first hook 100, a chute 101 and a second hook 102, the base 11 is provided with a slide rail 110 matching with the chute 101 and a positioning groove 111 snap-connected with the second hook 102, the bracket 10 passes through the first clip The hook 100 is snap-connected with the heating element 2 , the bracket 10 is slidably arranged on the slide rail 110 through the chute 101 and is snap-connected with the positioning groove 111 by the second hook 102 fixed on the base 11, the sliding direction of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com