Water boiler with two heating systems

A technology of heating system and water heater, which is applied to water heaters, fluid heaters, heat exchanger types, etc., can solve the problem of inconvenient maintenance of water heaters, and achieve the effects of shortening heating time, good thermal insulation effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

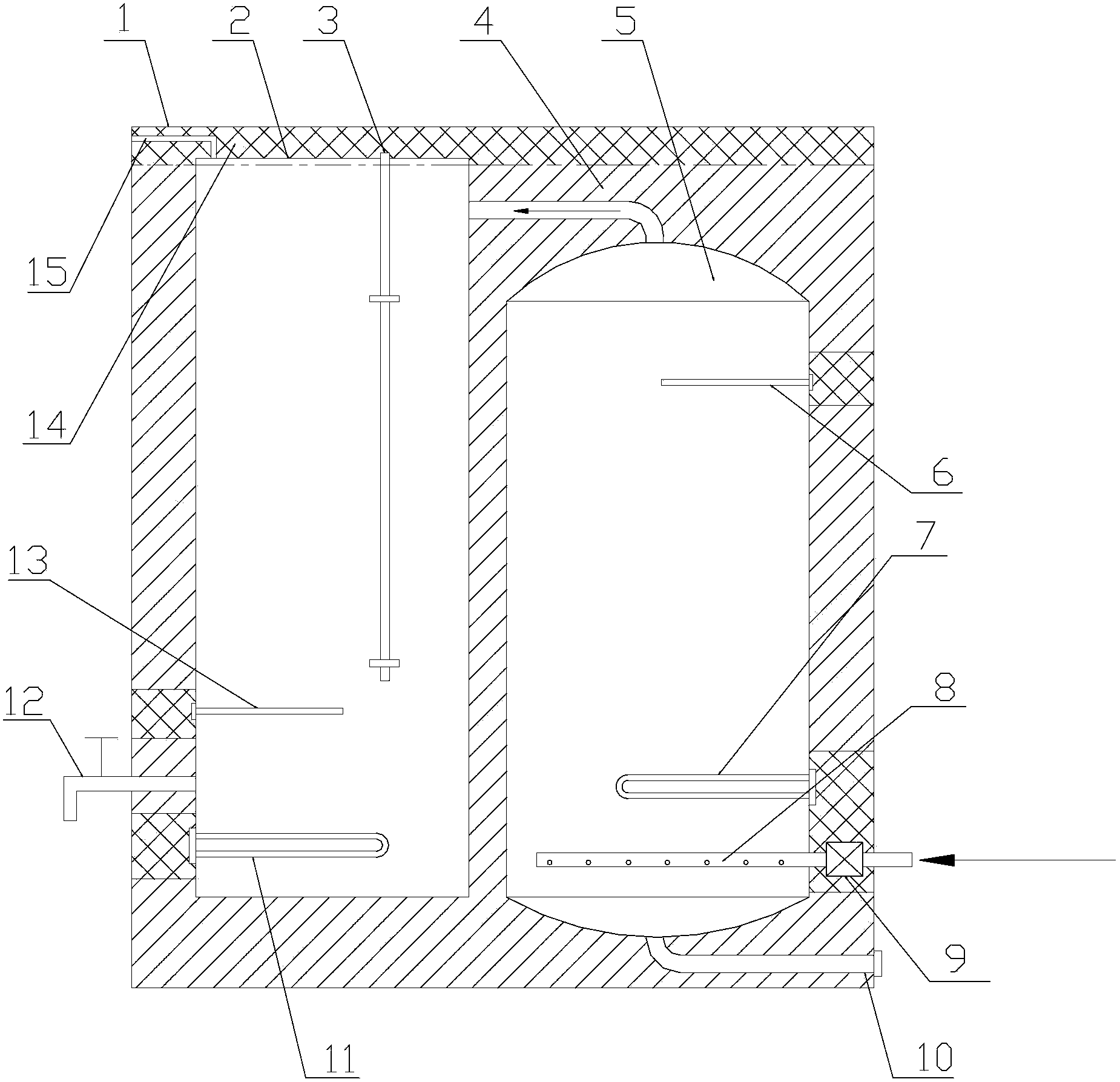

[0021] see figure 1 , in this embodiment, the water boiler of the dual heating system mainly includes a shell 1, a first-stage heating system and a second-stage heating system located in the shell 1, wherein the shell 1 is generally a sheet metal structure, and the shell 1 and the first An integral foam layer 4 is filled between the first-stage heating system and the second-stage heating system, wherein the integral foam layer 4 is formed by an integral foam process and is mainly used for heat preservation.

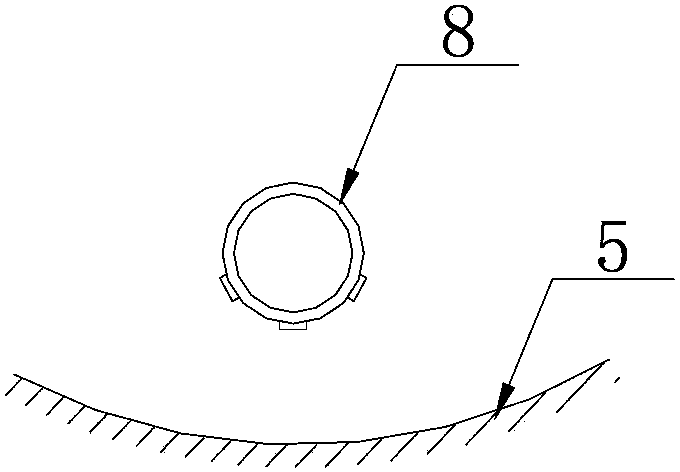

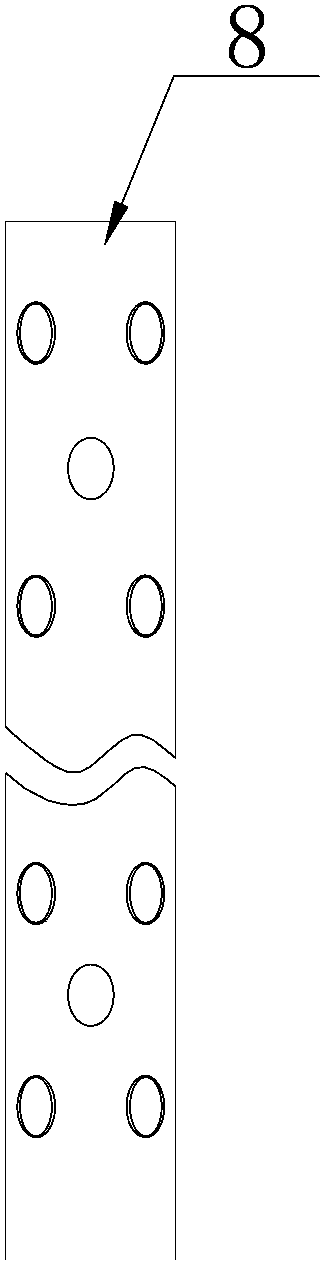

[0022] The first-stage heating system includes a first-stage heating water tank 5 , a first-stage temperature sensor 6 , a first-stage electric heating pipe 7 , a water supply pipe 8 , a water supply solenoid valve 9 and a sewage pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com