Detection method for three-dimensional space section roundness of large component

A technology of three-dimensional space and large-scale components, which is applied in the directions of measuring devices, section drawing, surveying and navigation, etc. It can solve problems such as irregular use of measuring tools, failure to meet the accuracy requirements of measurement, and reliability analysis of the brace measurement method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with embodiment the present invention is further described:

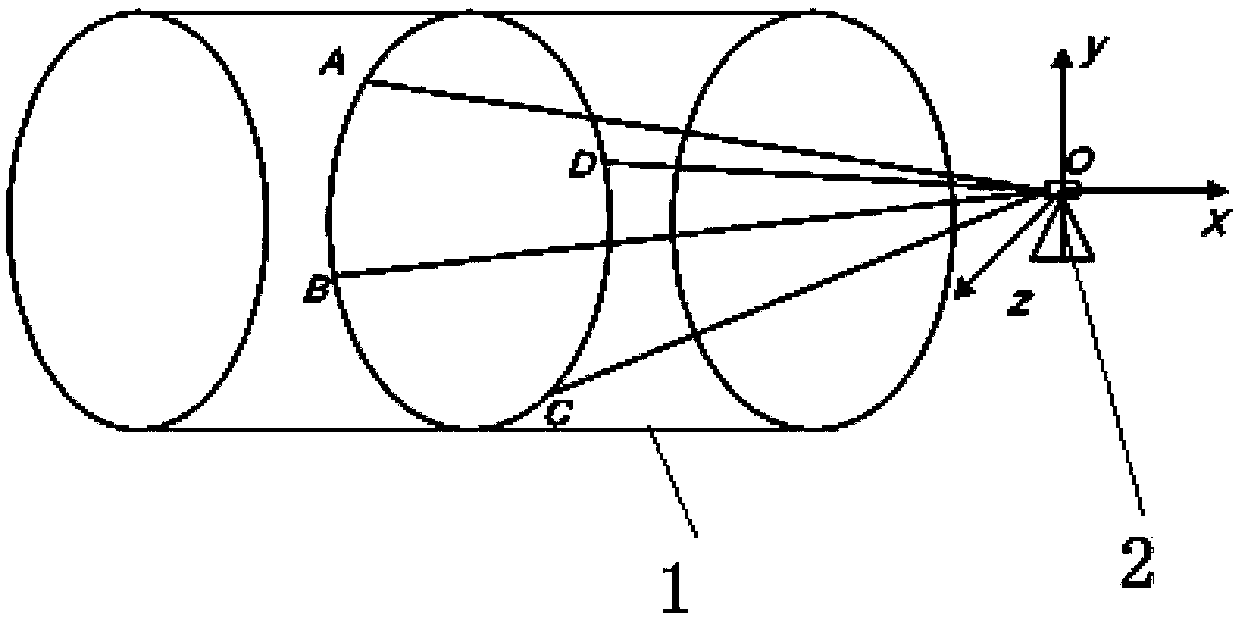

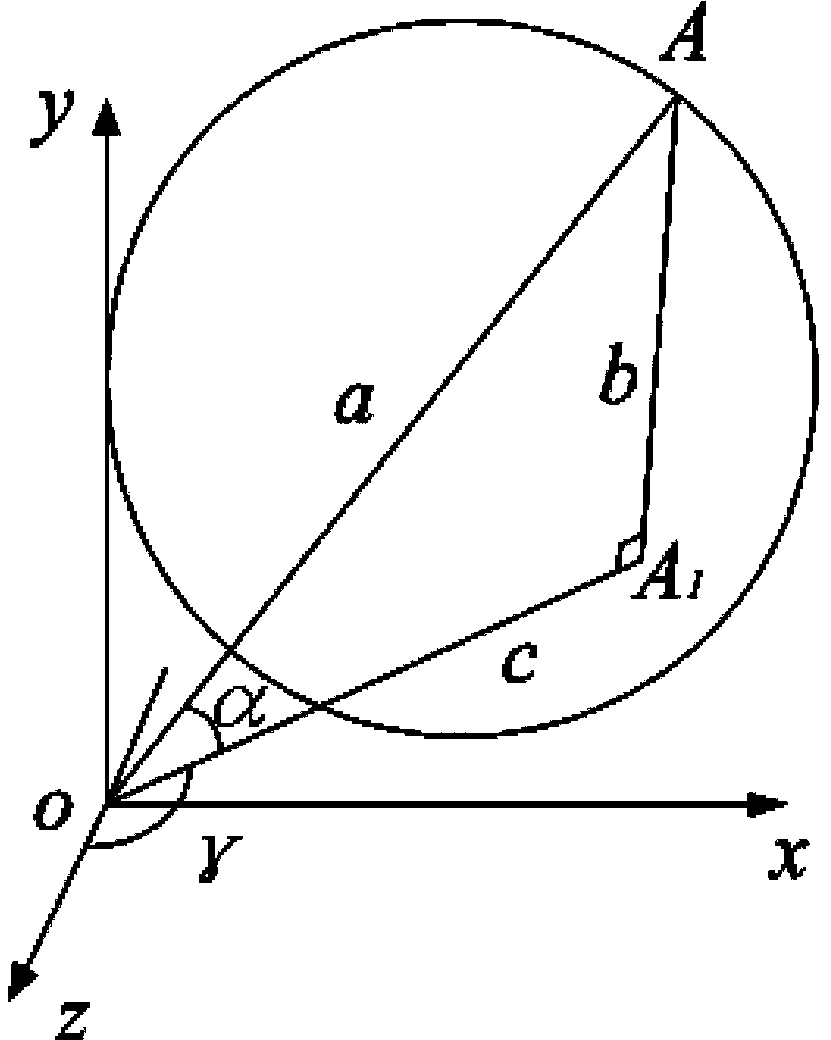

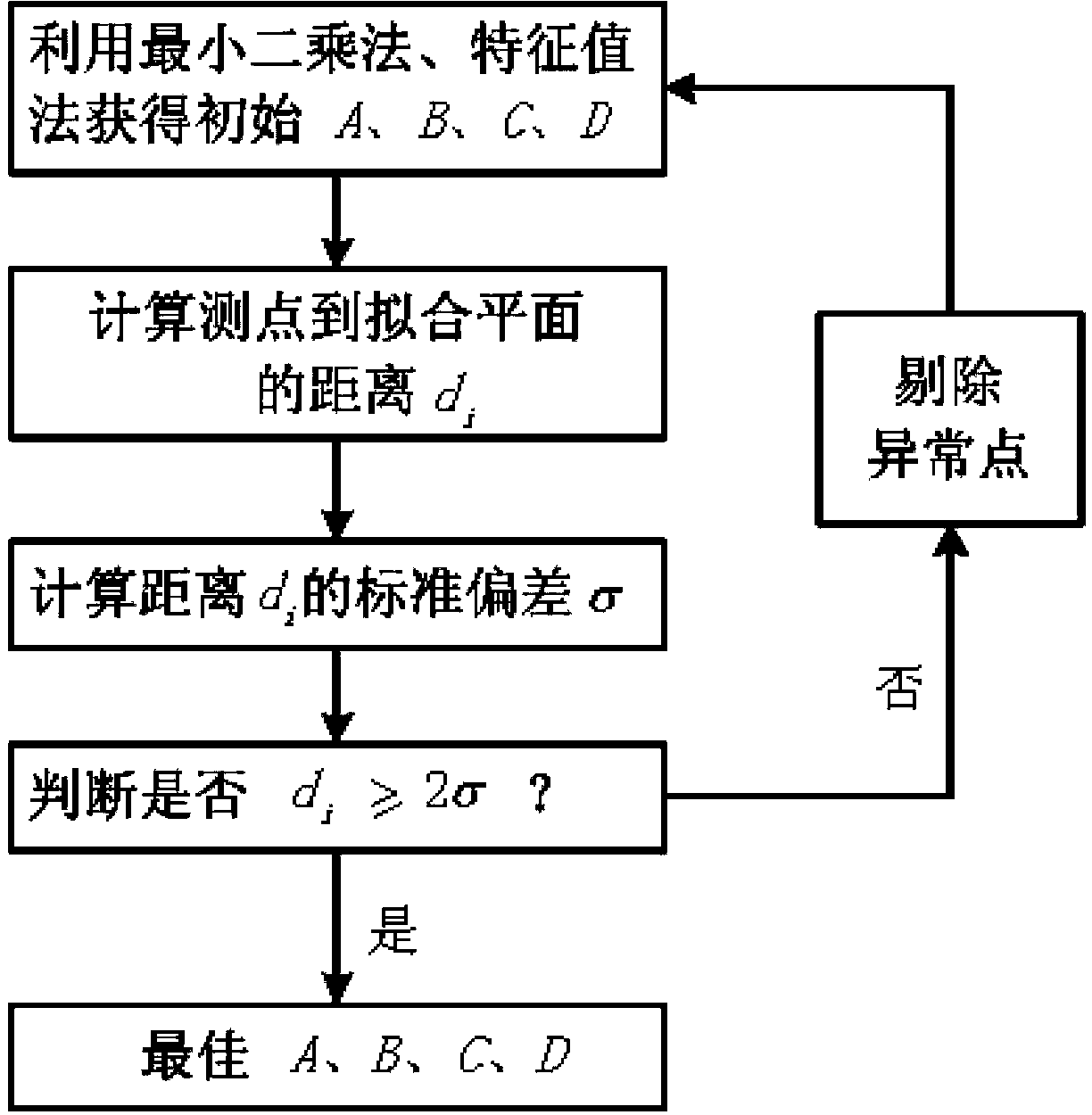

[0039] 1. The total station measures the three-dimensional coordinates of the bisection point of the section circumference

[0040] Laser ranging technology has the main advantages of high detection accuracy, fast response speed, non-contact without damage to the surface quality of the workpiece, the detection system will not reduce the accuracy due to the wear of the measuring head, is less affected by environmental factors, and can be used for online measurement. Widely used in the field of surveying and mapping.

[0041] As a non-contact measurement method, compared with the strut method, laser ranging technology can reduce the influence of human error in the process of component initial deflection evaluation, better meet the accuracy requirements of component initial deflection measurement, and at the same time can carry out strict accuracy reliability Analysis, while improving the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com