Multifunctional comprehensive test stand for dually-dry clutch

A technology of dry clutch and comprehensive test bench, which is applied in the field of functional test equipment for auto parts, can solve problems affecting optimal design development and quality improvement, and achieve the effects of novel design, improved production process, and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

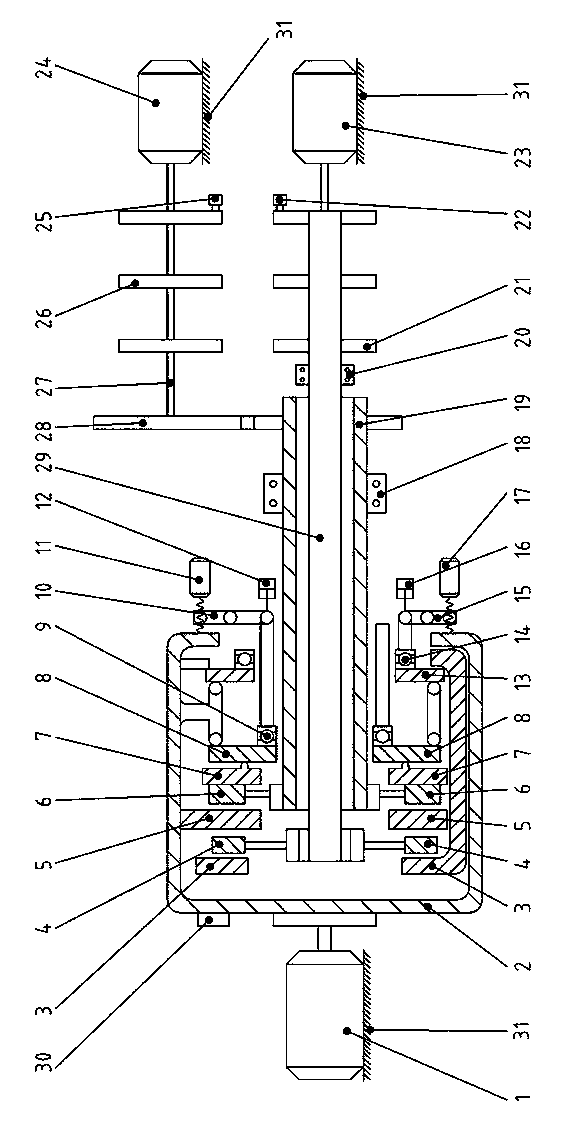

[0012] See figure 1 , The present invention has a test bench 31, on the test bench 31 is installed a drive motor 1 and two loading motors 23, 24, one of the loading motor 23 is connected to a main shaft 29, the other loading motor 24 through The transmission shaft 27 and the transmission gear set 28 are connected to a hollow shaft 19 for transmission. The hollow shaft 19 is sleeved on the main shaft 29. The main shaft 29 and the transmission shaft 27 are each equipped with three loading flywheels 21, 26 (the number of flywheels is determined according to the test load And quality), and the main shaft 29 and the hollow shaft 19 are equipped with rotational speed and torque sensors 18 and 20; the front end of the main shaft 29 extends out of the hollow shaft 19, and the outer end is designed with a spline structure for driving and connecting the tested clutch during the test C1 driven disc 4, the front end of the hollow shaft 19 is designed with a spline structure for driving and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com