Method for identifying typical flaws of forged piece based on ultrasonic phased array technology

An ultrasonic phased array and defect identification technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves to achieve the effects of rich detection information, intuitive results and high reliability

Active Publication Date: 2014-07-02

BEIJING UNIV OF TECH

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

First observe the defect echo shape

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

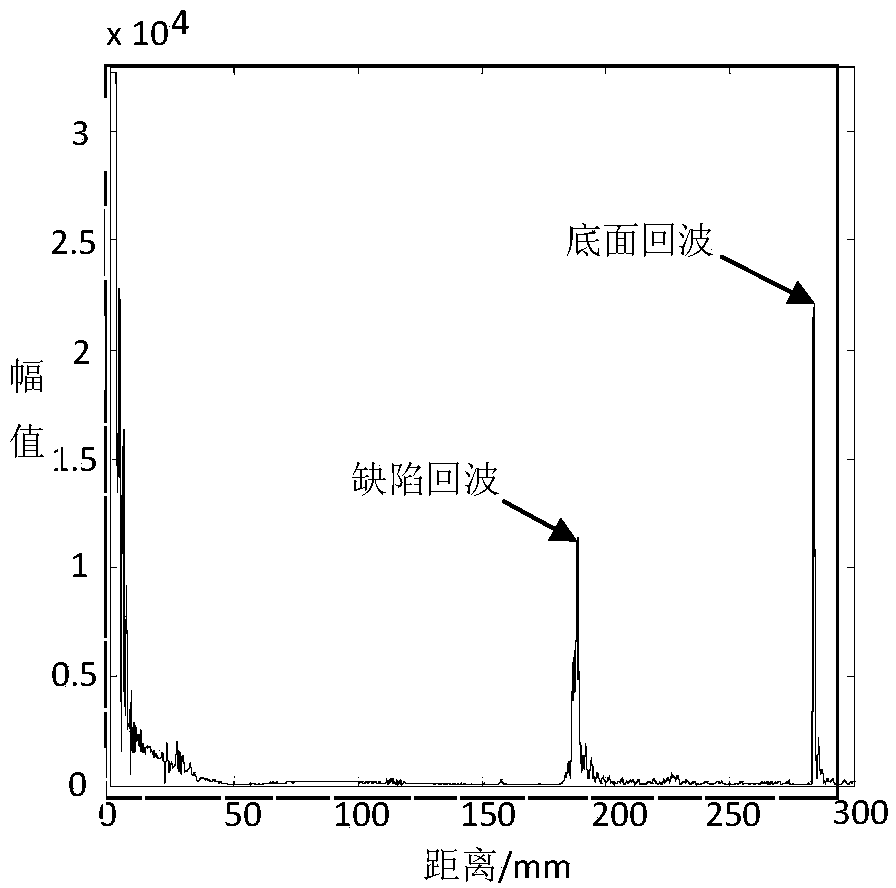

[0059] The detected forging in Example 2 is a cylindrical forging with a diameter of Φ450 mm and a length of 1050 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

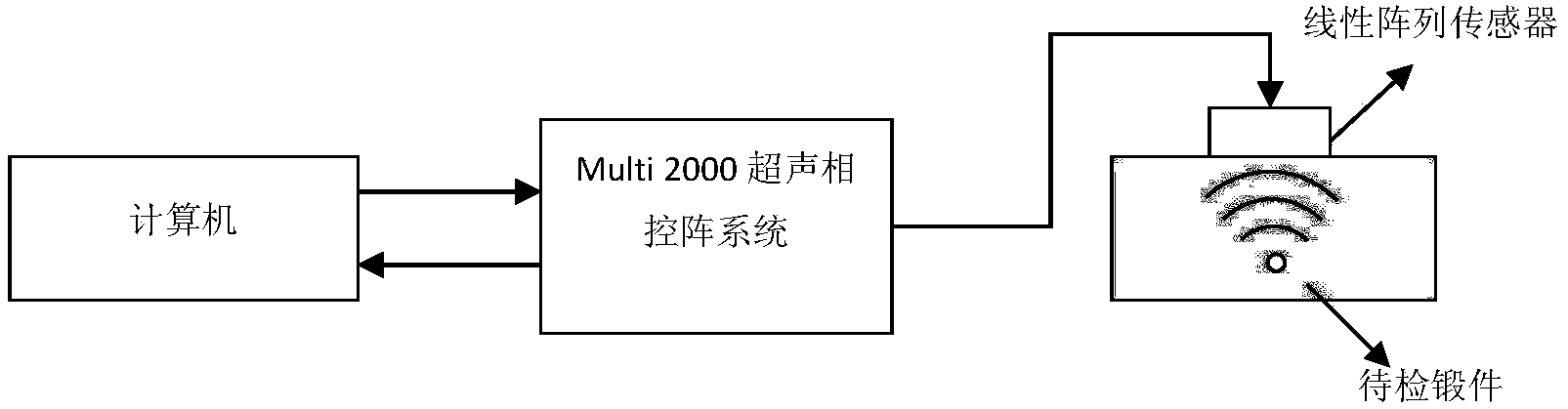

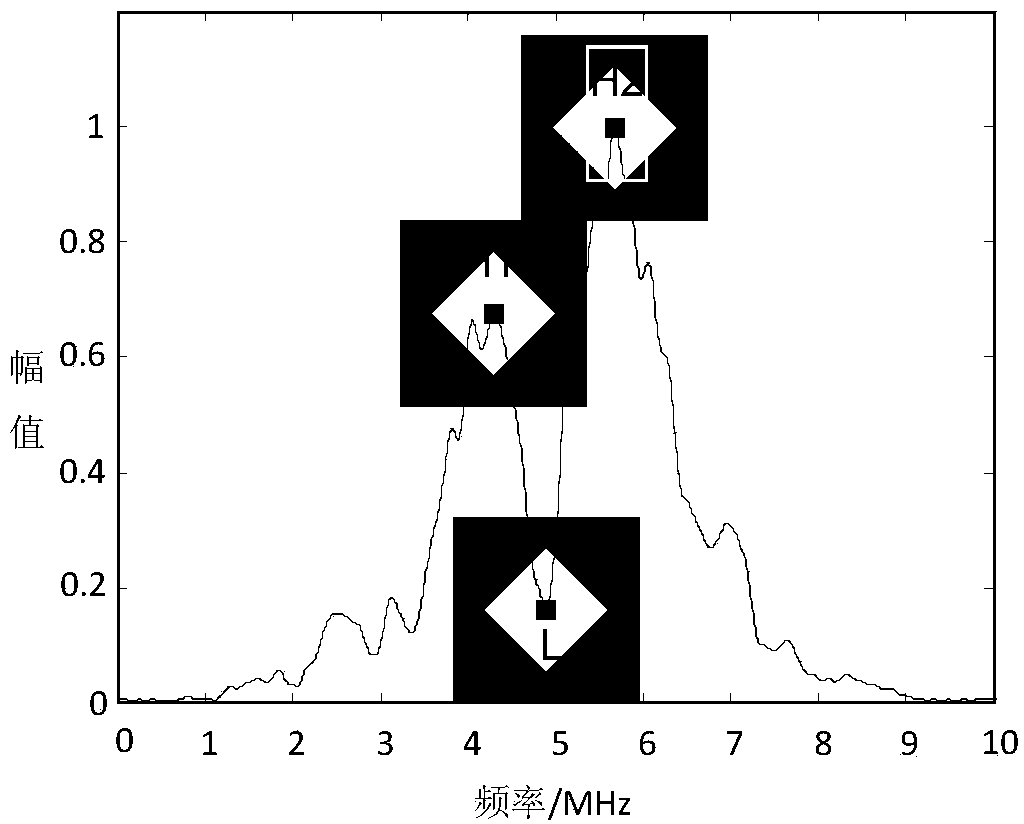

The invention discloses a method for identifying typical flaws of a forged piece based on an ultrasonic phased array technology and belongs to the field of nondestructive detection. The method is characterized in that hardware platforms for flaw identification comprise a computer (1), an ultrasonic phased array system (2) and a linear array sensor (3). The method comprises the following specific steps: exciting / receiving an ultrasonic signal by using the ultrasonic phased array system; sending and receiving the ultrasonic signal by using the linear array sensor; acquiring and detecting an A scanning signal and a sector scanning graph by using the computer; observing the shape of a flaw echo, calculating the spectrum characteristic information of the flaw echo, and observing the contour shape of a flaw vector scanning graph for flaw type determination. The invention provides the method for identifying the internal flaw type of the forged piece, and the problems that a conventional ultrasonic flaw detection method is low in detection efficiency, the flaw type cannot be accurately determined and the method highly depends on the professional experience of engineering staff are solved.

Description

technical field [0001] The invention relates to a method for identifying defects of forgings based on an ultrasonic phased array system. The method is mainly used for detecting and identifying defects of forgings and belongs to the field of non-destructive testing. Background technique [0002] As the basic components of various mechanical equipment, forgings are widely used in key fields such as aerospace, nuclear power, and ships. Due to the large volume and size of most forgings, and the complex shape and production process, it is easy to produce cracks, looseness and other defects in the production process. Defects in forgings will significantly reduce their mechanical properties, and even break during use, causing serious safety and quality accidents. Therefore, it is very important to inspect internal defects of forgings. [0003] Ultrasonic flaw detection, as one of the five conventional detection methods, has a high sensitivity to the detection of internal cracks, p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N29/04

Inventor 焦敬品杜礼马婷何存富吴斌

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com