Electrode structure manufacturing method for suppressing reversal domain lateral growth in ferroelectric crystal material polarization process

A ferroelectric crystal and lateral growth technology, applied in nonlinear optics, instrumentation, optics, etc., can solve problems such as domain merging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

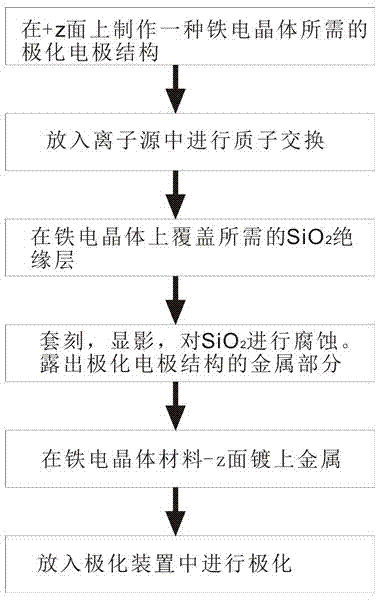

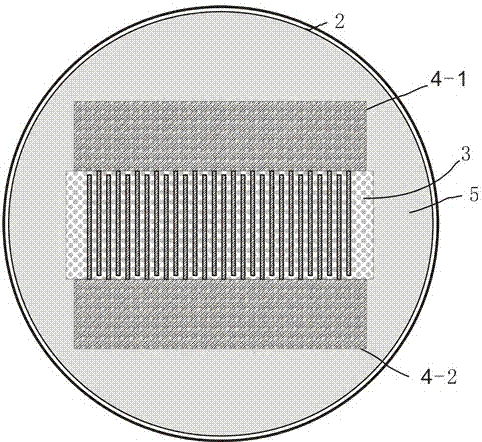

[0026] In this example, a periodically poled lithium niobate crystal with a period of 5.3 μm and a thickness of 1 mm is obtained through such polarization, which is applied to 488 nm blue light output. The specific implementation steps are as follows:

[0027] A fabrication method for suppressing the lateral growth of inversion domains during the polarization process of ferroelectric crystal materials. This method mainly weakens the dielectric constant on the surface of ferroelectric crystal materials to reduce the speed of inversion domain lateral growth. , so as to achieve the purpose of suppressing the lateral growth of inversion domains. Its production steps are as follows:

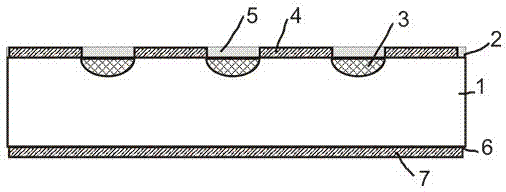

[0028] Firstly, on the +z surface 2 of the ferroelectric crystal material 1, an electrode structure 4 required for the polarization of the ferroelectric crystal material is produced by coating, photolithography and corrosion process methods or photolithography, coating and stripping process methods (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com