Industrial process fault detection method based on multiple classifiers and D-S evidence fusion

A technology of evidence fusion and multi-classifiers, applied in the direction of electrical testing/monitoring, etc., can solve the problems that cannot meet the actual industrial process monitoring requirements, unfavorable industrial process automation implementation, and cannot achieve satisfactory monitoring results, etc. Enhance understanding and operational confidence, improve the effectiveness of monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

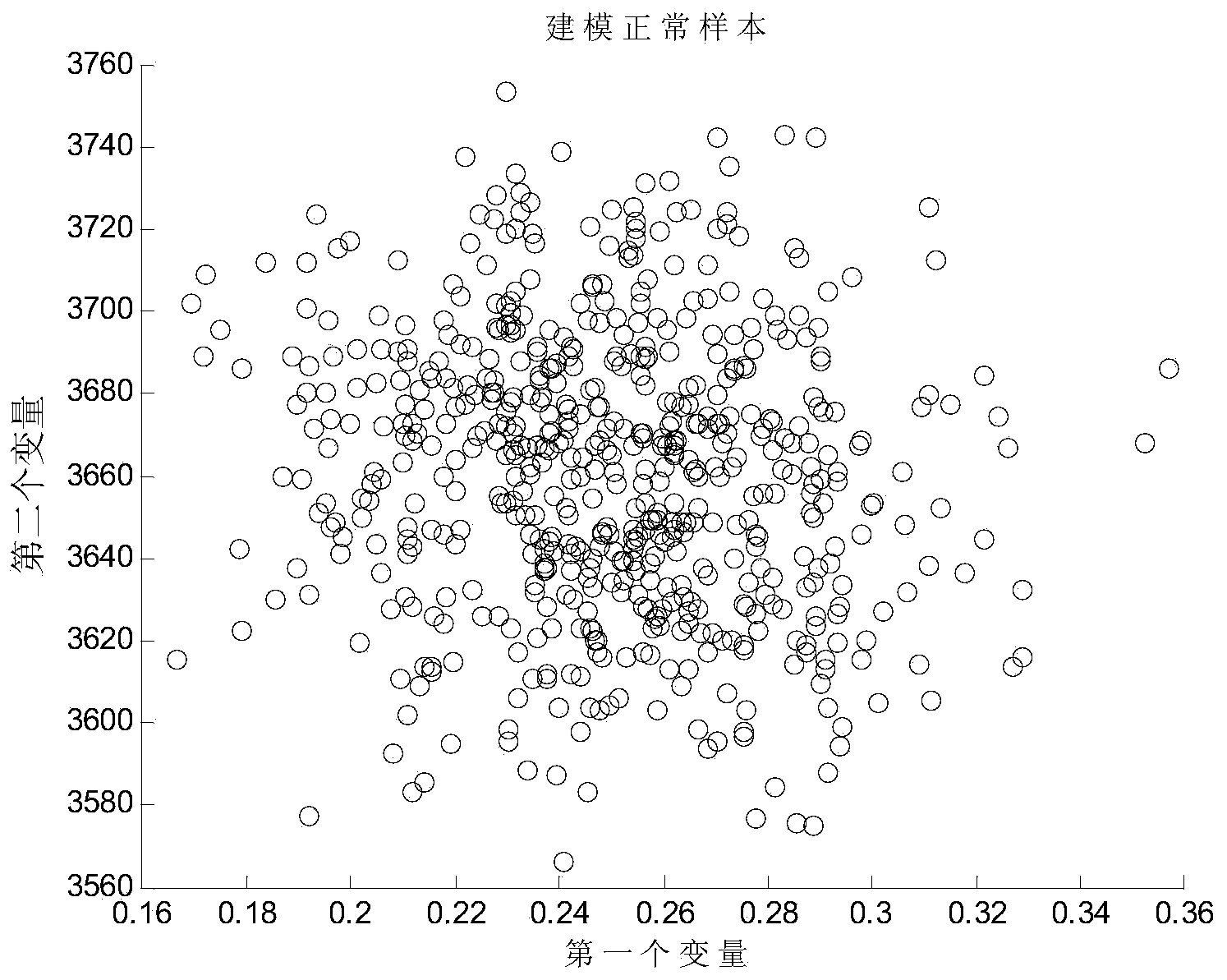

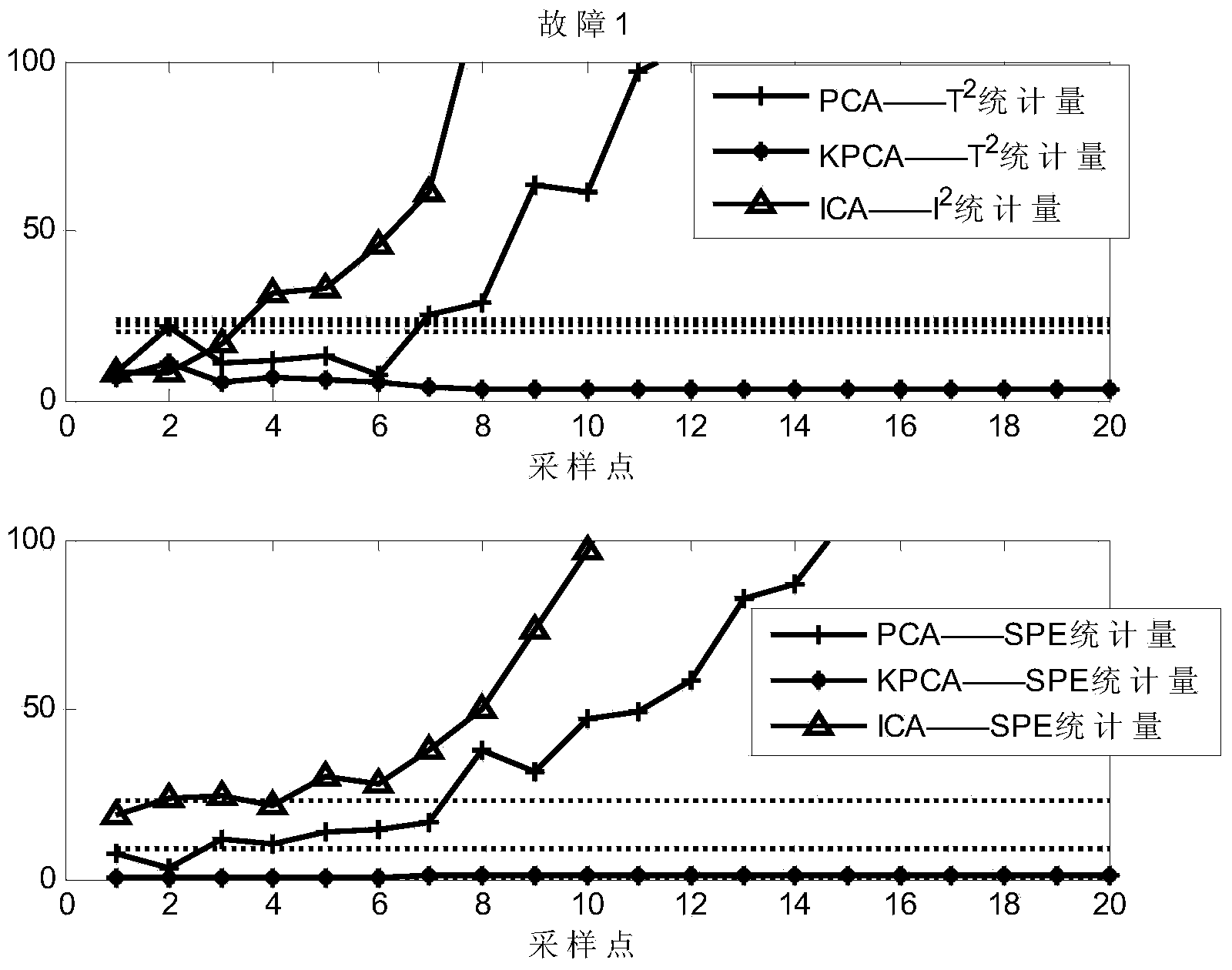

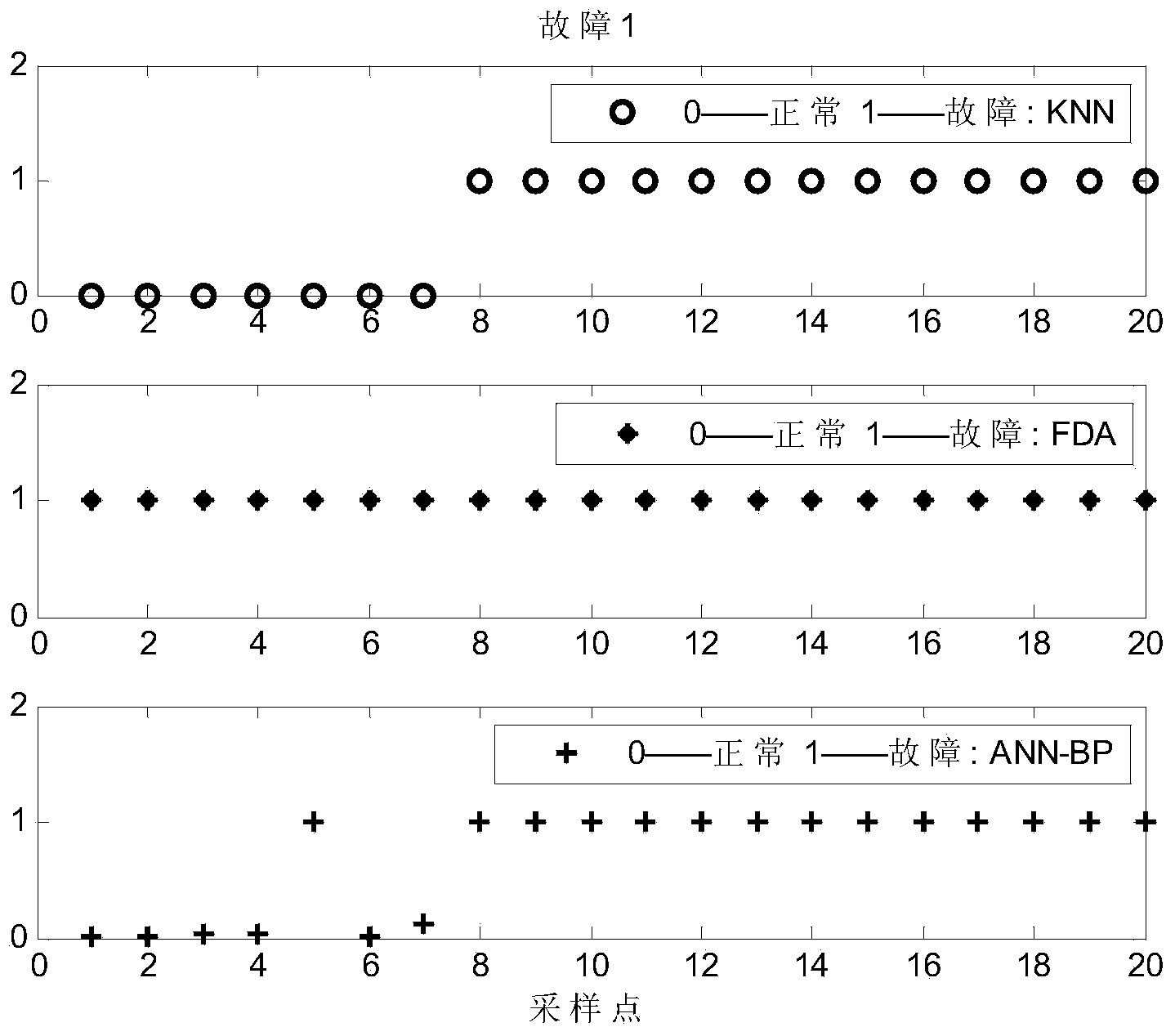

[0018] The present invention aims at the monitoring problem of the industrial process. Firstly, the distributed control system is used to collect the data under the normal working state, and then the data is processed in diversity, that is, independent repeated sampling is carried out to obtain a new training data set. On this basis, call Different classifier methods, establish corresponding classifier models, and establish two monitoring statistics T for unsupervised methods 2 and SPE and their corresponding statistical limits and SPE lim , to build label classes for supervised methods. Store all process model parameters in the database for future use. When monitoring a new batch of data, first use different classifier monitoring models to monitor it, and obtain corresponding monitoring results. Then the final decision of the state of the data is obtained through the D-S evidence theory.

[0019] A kind of industrial process fault detection method based on multi-classifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com