Method for quantitatively analyzing EBSD measured body-centered cubic alloy solidification structure grain sizes

A technology for quantitative analysis and solidification structure, applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve problems such as the inability to evaluate grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

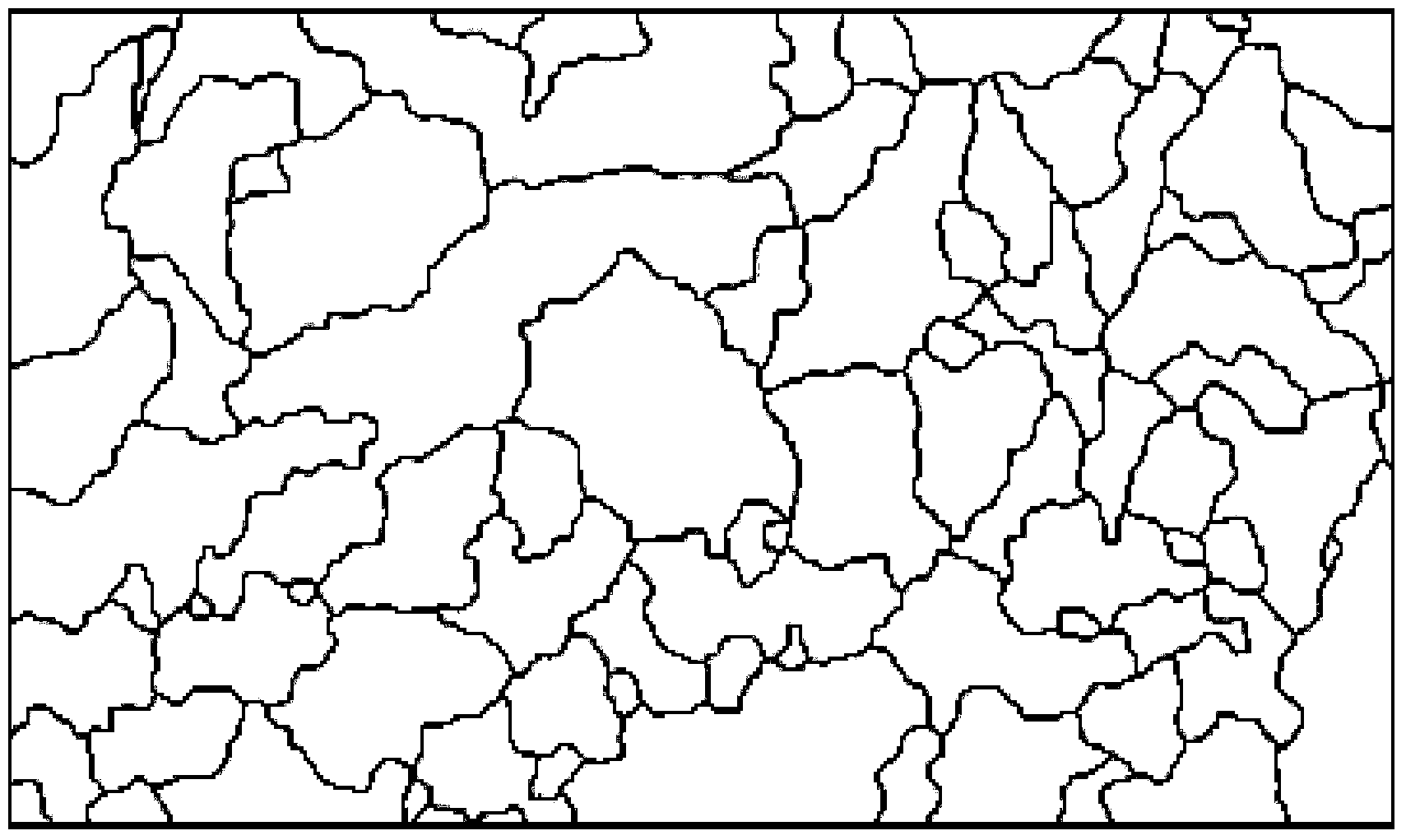

[0024] Embodiment 1: In this embodiment, a method of quantitatively analyzing EBSD to measure the grain size of solidified structure of body-centered cubic alloy is carried out according to the following steps:

[0025] 1. Obtain EBSD data: read the data file output by EBSD after analyzing and testing the surface of body-centered cubic alloys, obtain the space step size (Δx m and Δy m) used in the EBSD measurement process, and obtain the two parameters of each test point. dimensional space coordinates P (x i m, y i meters) and get the three Euler angles for each test point degree, θ i degree and ψ i Spend;

[0026] 2. Create a two-dimensional array: define x described in step 1 i The minimum value of x min 、x i The maximum value is x max 、y i The maximum value is y max and y i The minimum value of y min ;Find four points (x min ,y min ), spatial point (x max ,y max ), spatial point (x max ,y min ) and spatial point (x min ,y max ); establish a two-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com