Polygonal enamel wire for electromagnetic winding and motor comprising same

A polygonal enameled wire and electromagnetic winding technology, which is applied to the shape/style/structure of winding conductors, flexible cables, circuits, etc., to reduce costs, reduce device volume, and improve space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

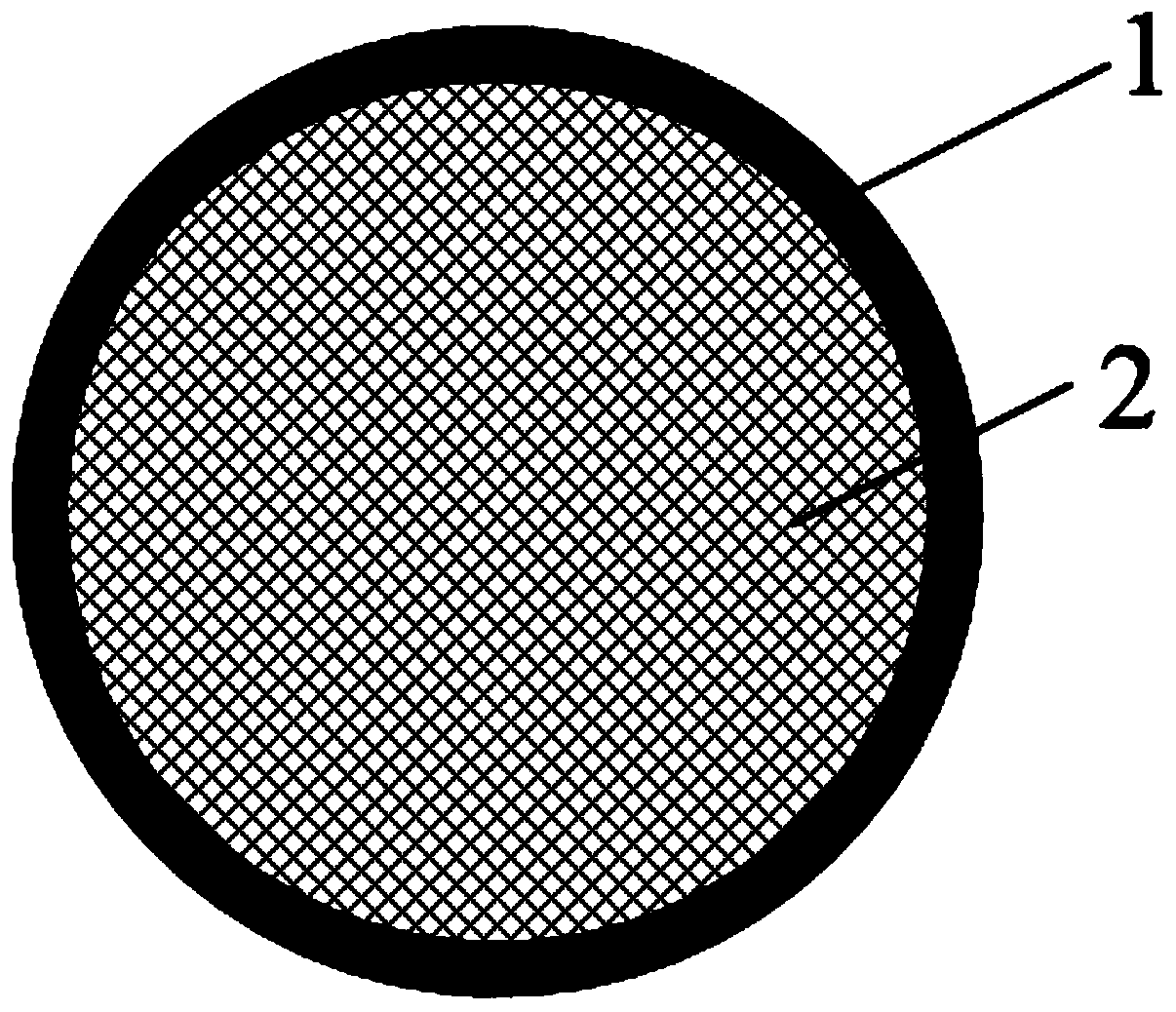

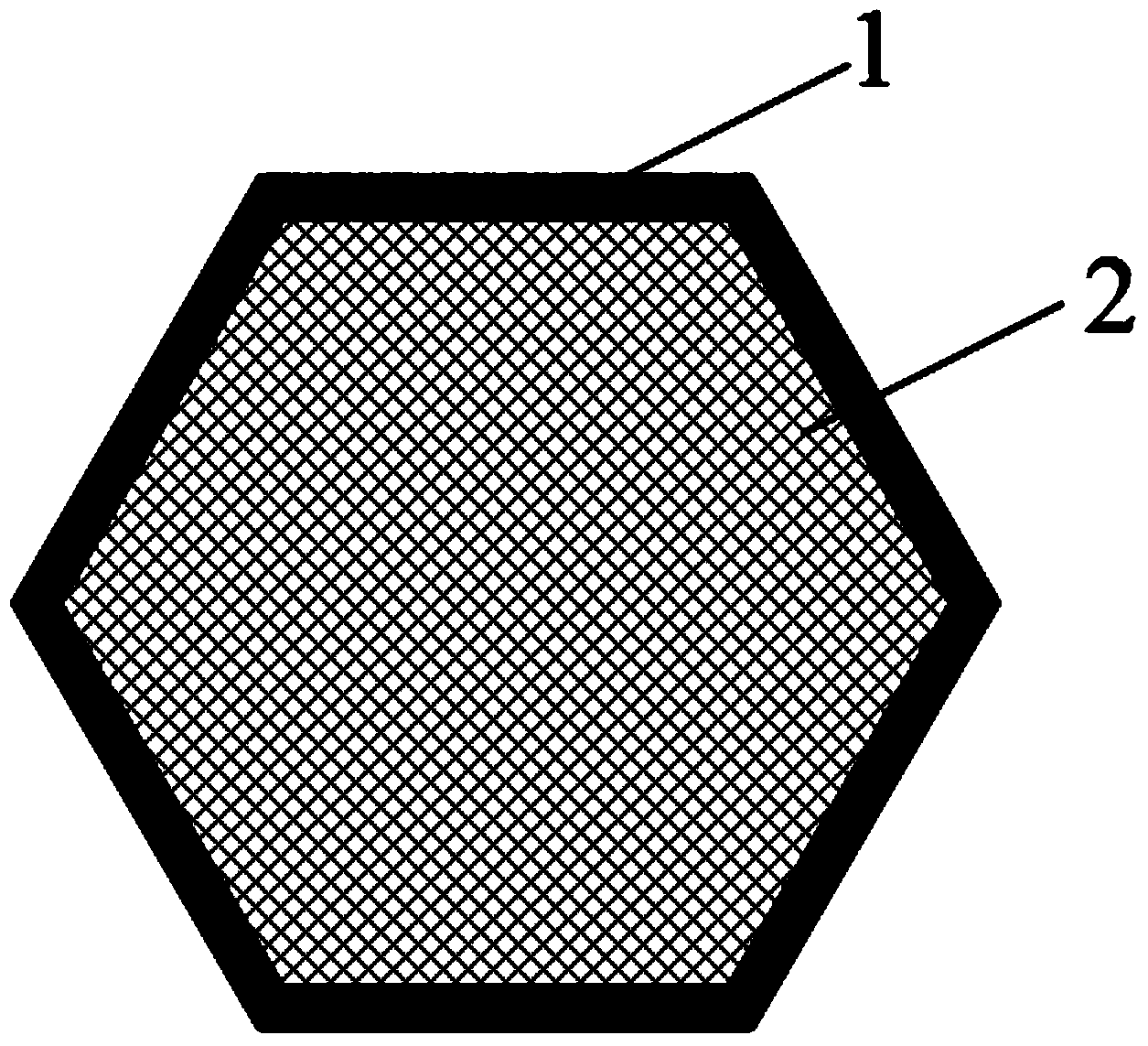

[0023] In Example 1, the polygonal enameled wire is hexagonal. Enameled wires formed with other polygons still fall within the scope of the present invention.

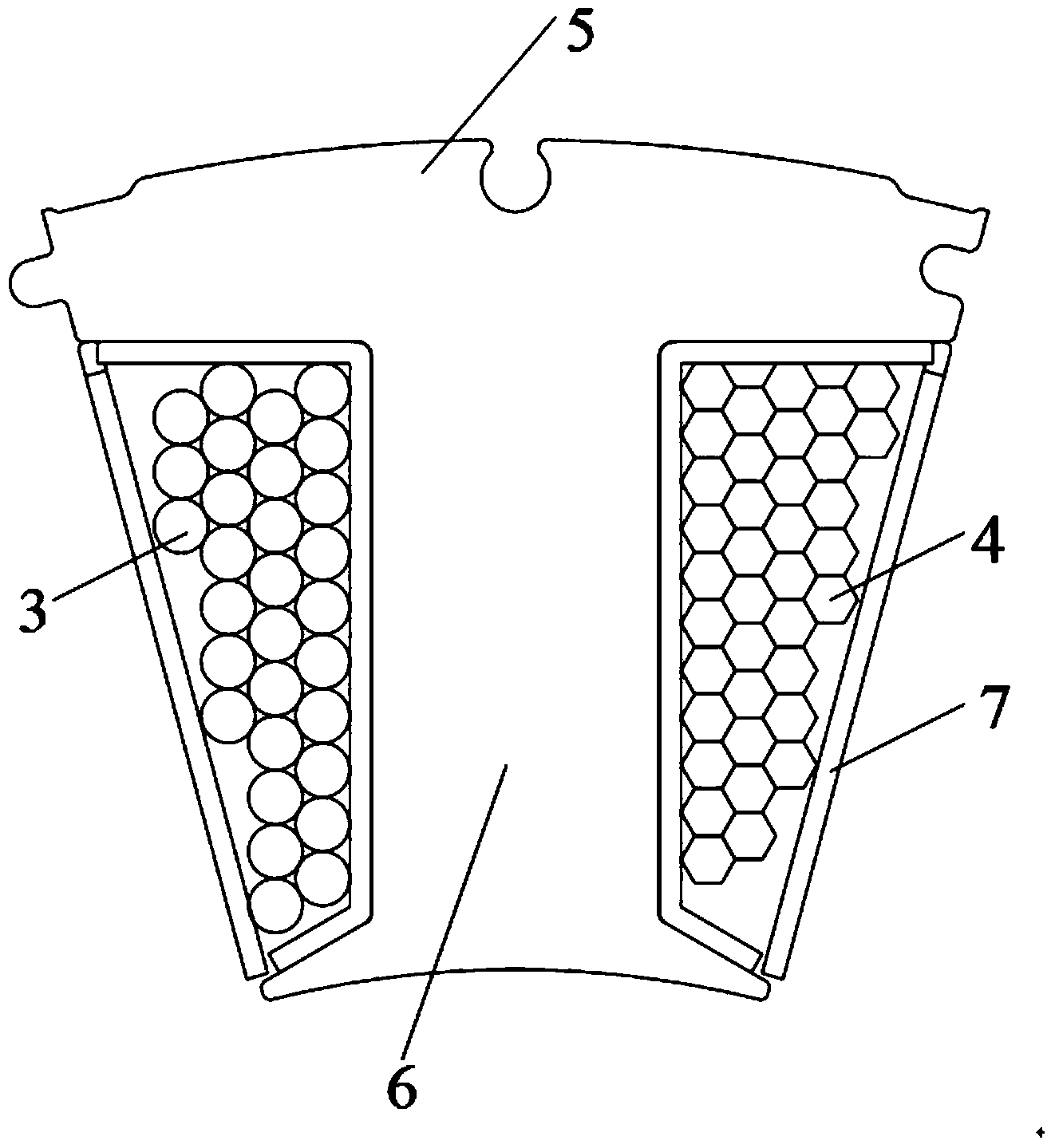

[0024] The polygonal enameled wire in the present invention can be used for electromagnetic windings, image 3 It is a schematic diagram of the comparison between the circular enameled wire and the hexagonal enameled wire in the motor stator. From image 3 It can be seen from the partial sectional view of the stator core of the motor, wherein the slots on both sides of the stator teeth 6 have the same area, and two kinds of enameled wires are respectively placed: the circular enameled wire in the prior art and the hexagonal enameled wire in the present invention. The circular enameled wire 3 is placed on the left side of the stator tooth 6 . The hexagonal enameled wire 4 is placed on the right side of the stator tooth 6 (of course, other polygons can also be placed). Obviously, with the polygonal enameled wire, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com