Local random point contact solar cell with back electrode and preparing method thereof

A technology for solar cells and back electrodes, applied in the field of solar cells, can solve the problems of surface passivation and electrode contact of silicon solar cells, and achieve the effects of being beneficial to mass production, increasing short-circuit current and open-circuit voltage, and improving long-wave response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

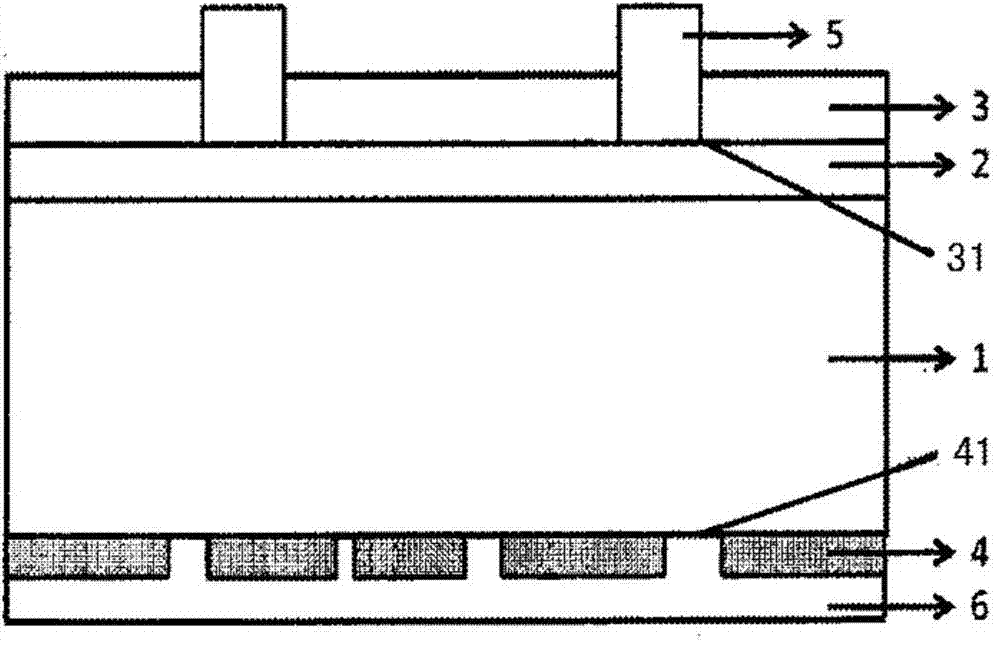

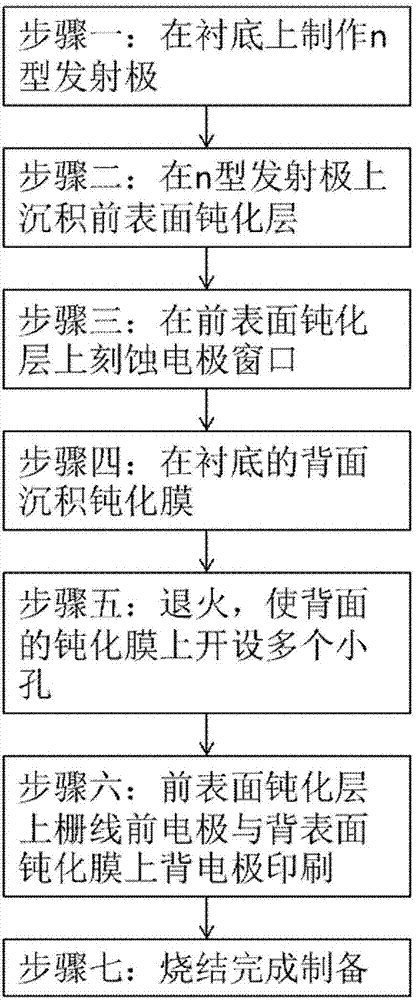

[0028] First, the realization principle of the present invention is briefly described

[0029] The method for forming the electrode local point contact structure provided by the present invention is to deposit Al on the silicon surface 2 o 3 film, because the film contains a large number of mobile hydrogen atoms, hydrogen atoms will combine to form hydrogen gas during the annealing process, so from Al 2 o 3 escapes from the film, making the Al 2 o 3 Blistering occurs in the film. A round hole will naturally be left at the foaming place, and there is no Al in this round hole. 2 o 3 The silicon surface is exposed by covering with the film. When there is electrode metal covered to Al 2 o 3 When it is on the film, a part of the metal will fall into the hole and contact with the silicon, so as to realize the electrode local point contact model of the silicon material with surface passivation.

[0030] Based on the above realization principles, the present invention propos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com