LED lamp filament piece, manufacturing method of LED lamp filament piece and LED lamp filament piece bulb

A technology for LED filaments and light bulbs, which is applied in lighting and heating equipment, electrical components, circuits, etc. It can solve the problems of difficult large-scale production of LED filaments, low yield, long length of LED filaments, etc., and achieve streamlined SMT placement process, The effect of reducing production cost and rapid prototyping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

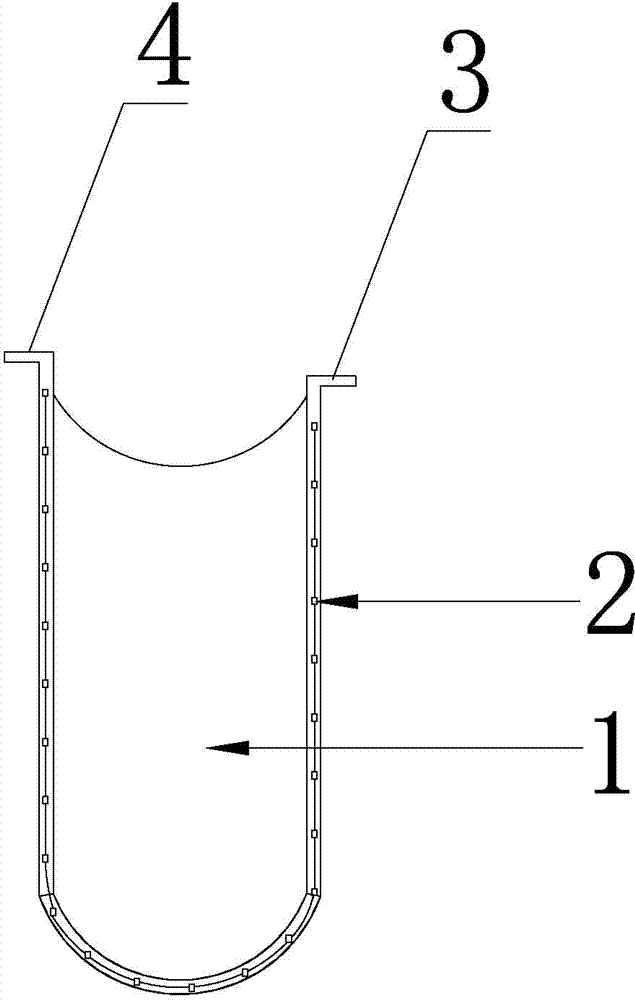

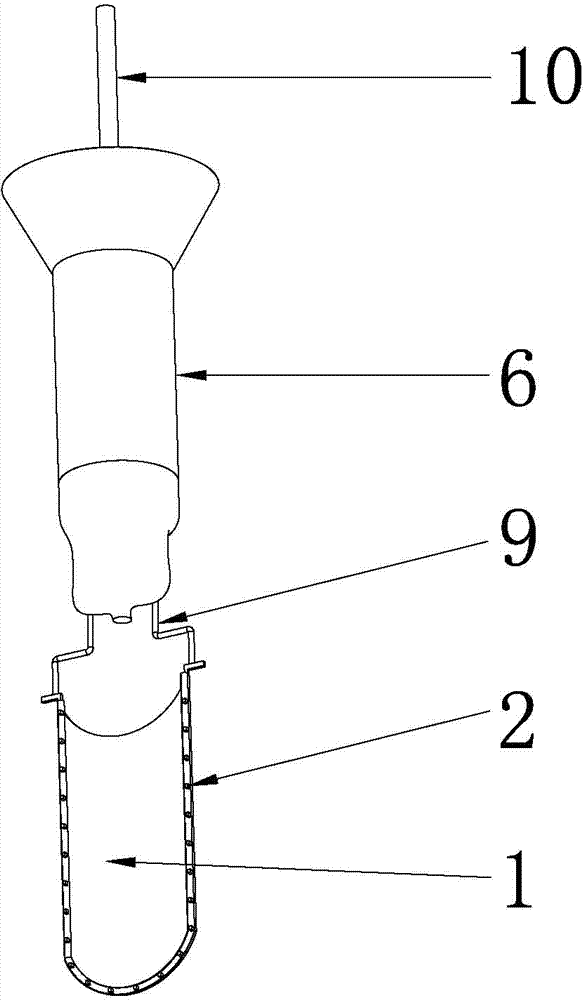

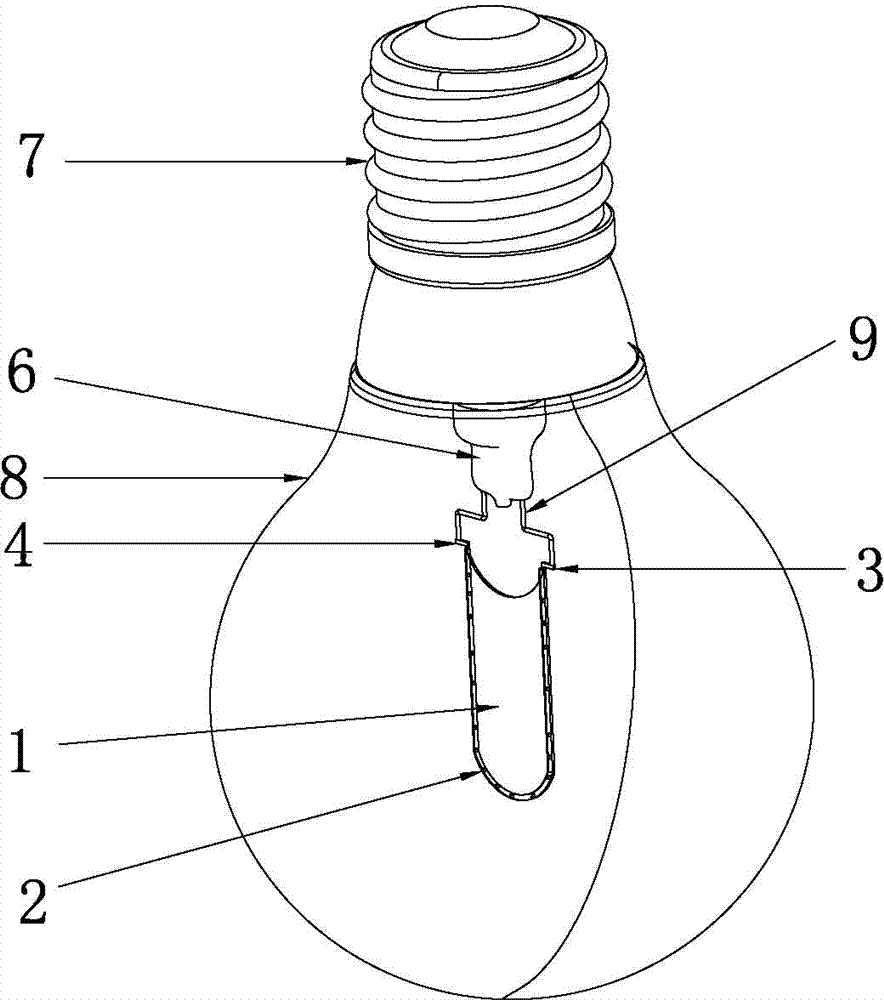

[0038] In this example, please refer to Figure 1 to Figure 5 , provided by the present invention one An LED filament sheet, including a substrate 1, several LED chips 2, and fluorescent glue (not shown in the figure) covering the LED chips 2, the fluorescent glue is composed of a transparent colloidal material mixed with phosphor powder, coated A protective layer of the LED chip 2 is formed on the periphery of the LED chip 2, and an optical lens of the LED chip 2 is formed at the same time, which can increase optical reflection, reduce light loss, and improve light efficiency.

[0039] Several LED chips 2 described in the first embodiment are arranged in sequence according to U-shaped rules and connected in series to form U-shaped LED filaments (such as figure 1 shown), and fixed on at least one side of the substrate 1, in this embodiment, the U-shaped LED filament is only installed on one side, and the side is set outward during use; the substrate 1 A first electrode pin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com