UV color mirror glass and processing process thereof

A glass and colored mirror technology, applied in the field of UV colored mirror glass, can solve the problems of insufficient aesthetic feeling and insufficient color, and achieve the effect of increasing visual beauty and rich color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

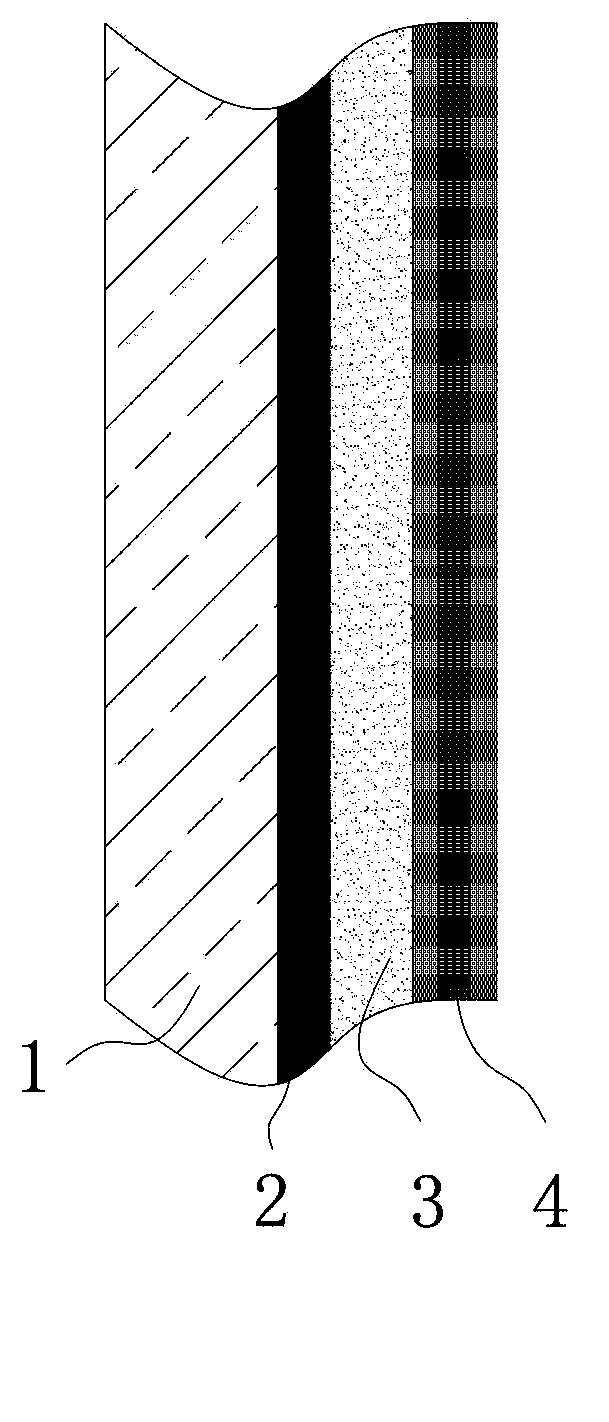

[0017] Such as figure 1 Shown is a structural schematic diagram of an embodiment of the present invention, a UV colored mirror glass, including a glass layer 1, and a UV ink layer 2, a coating layer 3 and a paint layer 4 are sequentially provided on the plate surface on one side of the glass layer.

[0018] In this embodiment, hollow patterns are arranged on the UV ink layer.

[0019] In this embodiment, the coating layer is an opaque colored coating, so as to be conveniently used in various space arrangements requiring privacy.

[0020] The material included in the paint layer is silver mirror paint, which has better light perception effect and better visual experience for observers.

[0021] A kind of technique of processing UV colored mirror glass provided by the invention comprises the following steps:

[0022] 1) Cleaning thin plate-shaped glass materials;

[0023] 2) Put the cleaned glass material into the screen printing machine for UV ink printing, draw a hollow pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com