Shaft-adjusting pipe grinding machine

A tube and shaft type technology, which is used in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding workpiece supports, etc., can solve the problems of inconvenient operation, difficult to ensure accuracy, and inability to grind and shape at one time, and improve work efficiency. , the effect of reducing labor intensity and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be described in further detail below in conjunction with the drawings, wherein the same symbols in all the drawings represent the same or similar components, and the drawings in the description are in simplified form and are only for understanding the specific structure of the present invention.

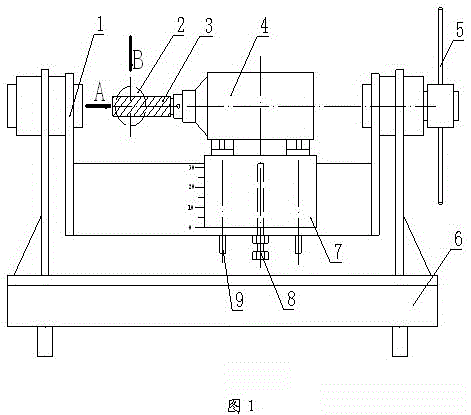

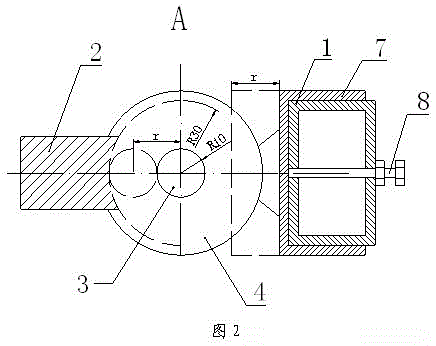

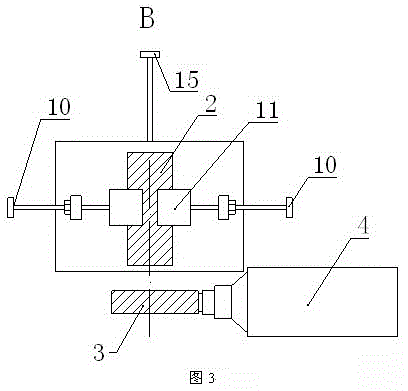

[0026] Such as figure 1 , Figure 4 As shown, the shaft-adjusting type pipe grinding machine of the present invention includes a frame 6, a rotating frame 1 and a workpiece adjustment device;

[0027] Both ends of the rotating base 1 are connected to the frame 6, and the rotating base 1 is connected with a relatively movable U-shaped adjusting seat 7 through an adjusting screw 8, and the rotation of the adjusting screw 8 can adjust the U-shaped The relative position of the adjustment seat 7 on the adjustment screw rod 8, the U-shaped adjustment seat 7 is provided with a motor 4, the output shaft of the motor 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com