Safe handle mounting bracket structure

A mounting bracket and safe technology, applied in the directions of transportation and packaging, special positions of vehicles, vehicle parts, etc., can solve the problems of complicated installation and operation of safety handles, time-consuming and economical costs, inconvenient disassembly and assembly, etc., and achieves quick connection and long service life. , the effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

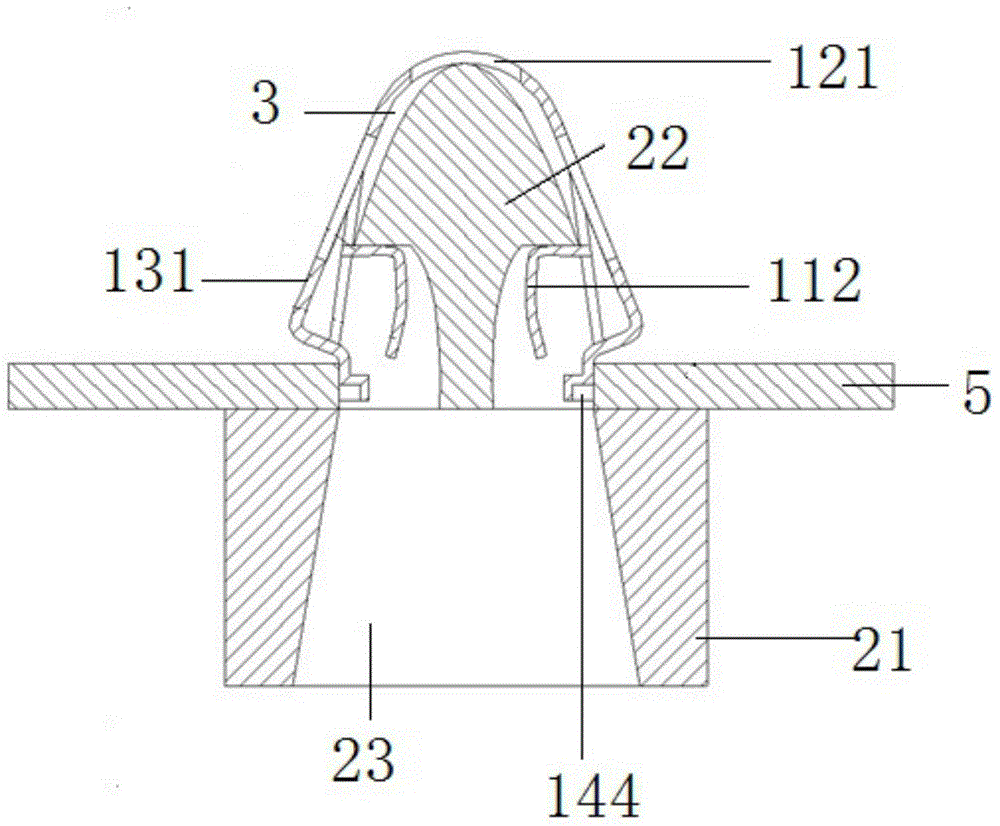

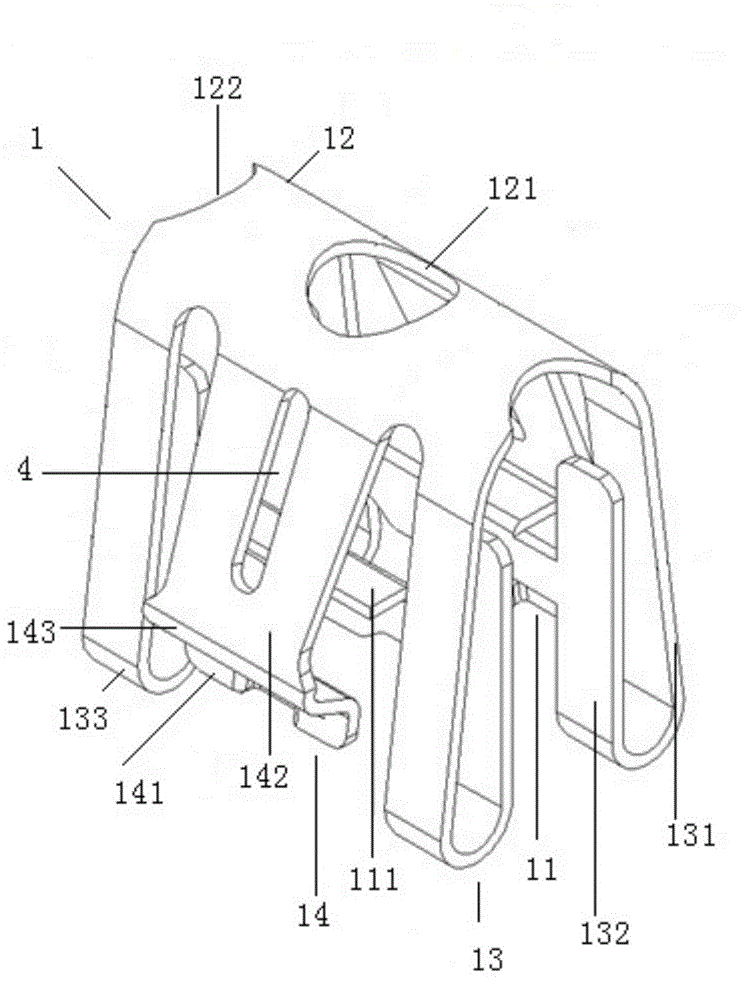

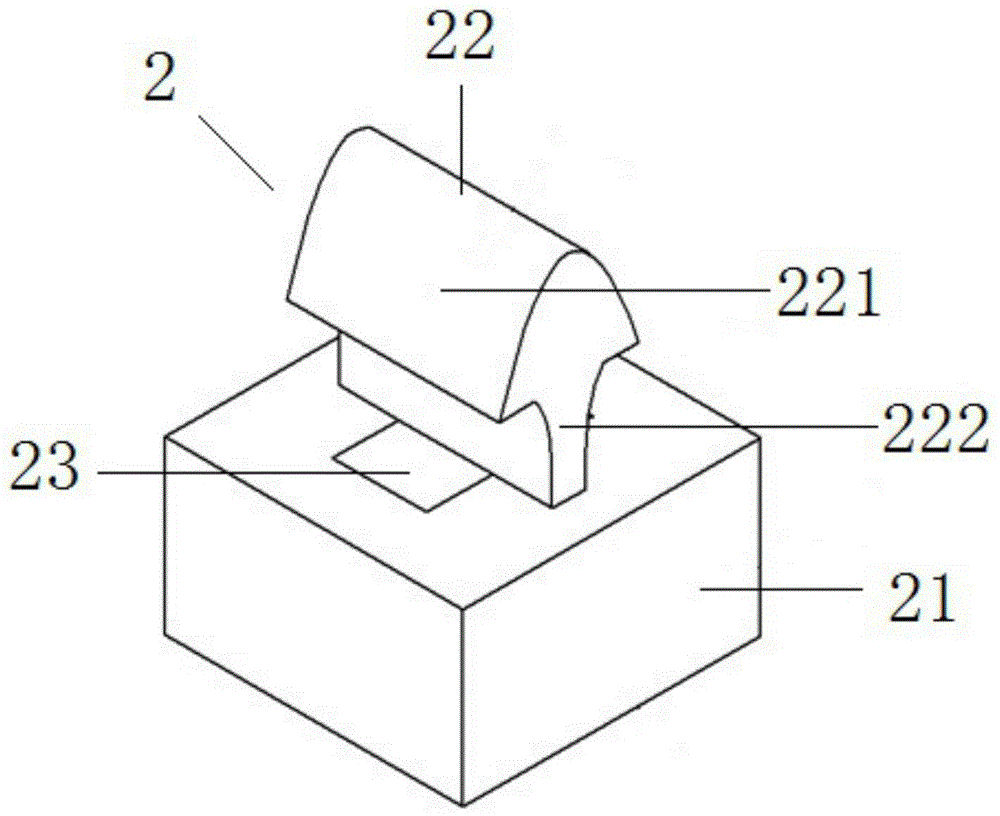

[0021] like figure 1 , figure 2 , image 3The safety handle installation bracket structure shown includes a sheet metal hole connection socket 1 and a plug part 2, and the sheet metal hole connection socket 1 includes a clamping part 11, a central top plate 12, and two sides connected to the central top plate 12. Several shielding parts 13, the middle part of both sides of the central top plate 12 is connected with an external engagement part 14, and the external engagement part 14 includes a pressing plate 141 for contacting with the inner edge of the sheet metal hole, and a The outer engaging plate 142 at an angle of 15 to 60 degrees, the connecting section of the pressing plate 141 and the outer engaging plate 142 forms an anti-off part 143, and the lower part of the pressing plate 141 is provided with a pincer groove 144, so The clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com