Vibration absorbing device, vehicle spare tire support with same and vehicle

A technology of vibration damping device and spare tire rack, which is applied to vehicle parts, transportation and packaging, spare tire layout, etc., can solve the problems of increasing vehicle curb weight, increasing vehicle manufacturing and use costs, etc., and achieve good vibration reduction effect, Improve the life of the vehicle and improve the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

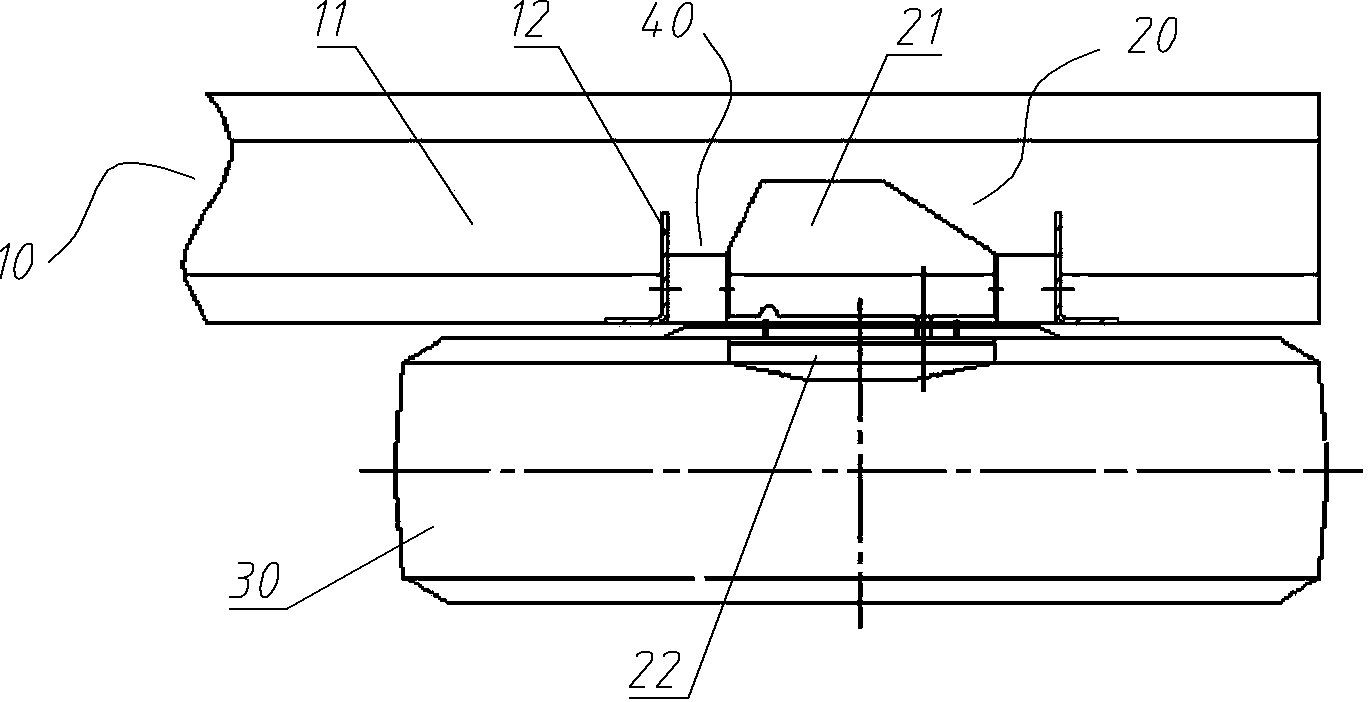

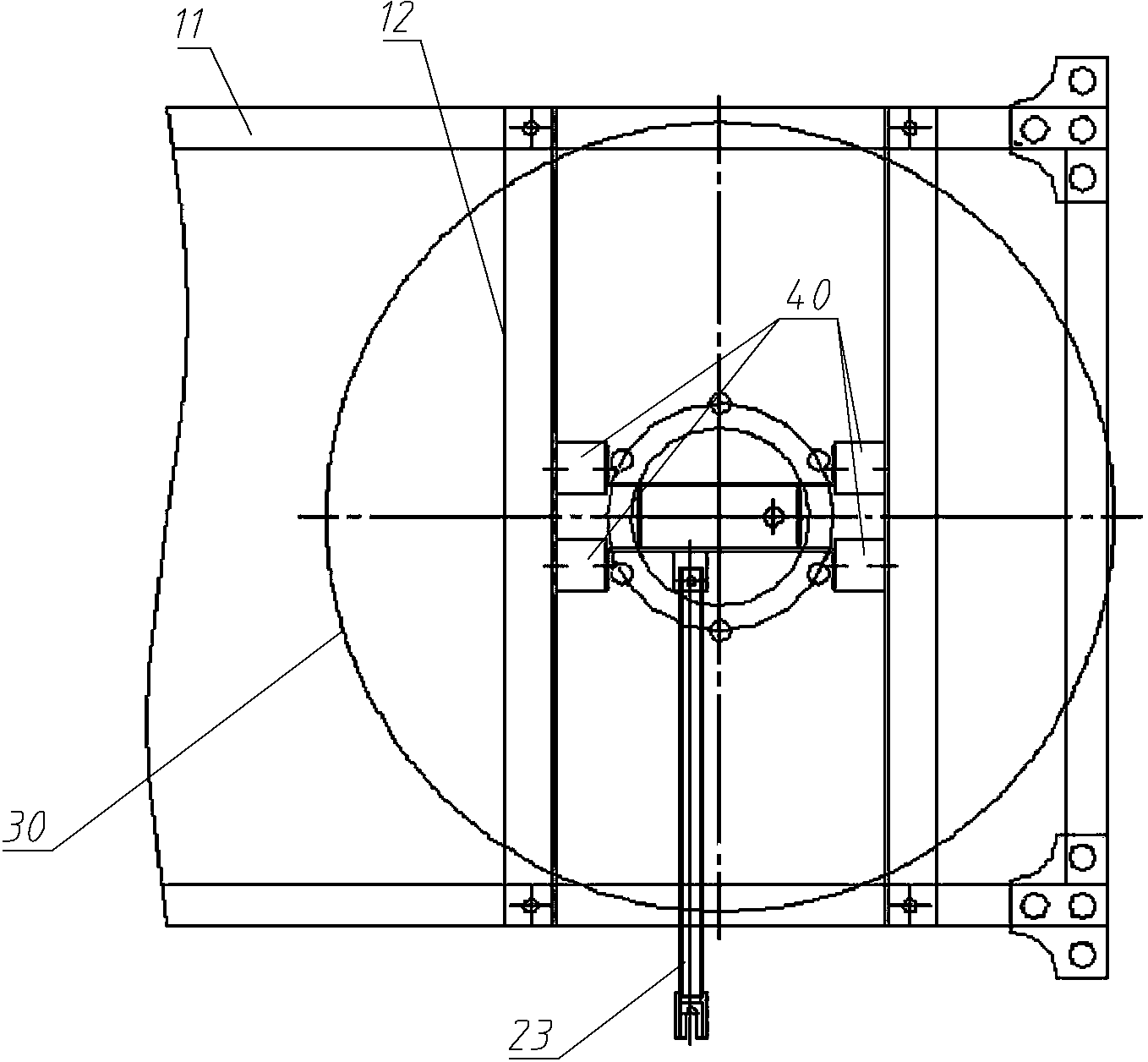

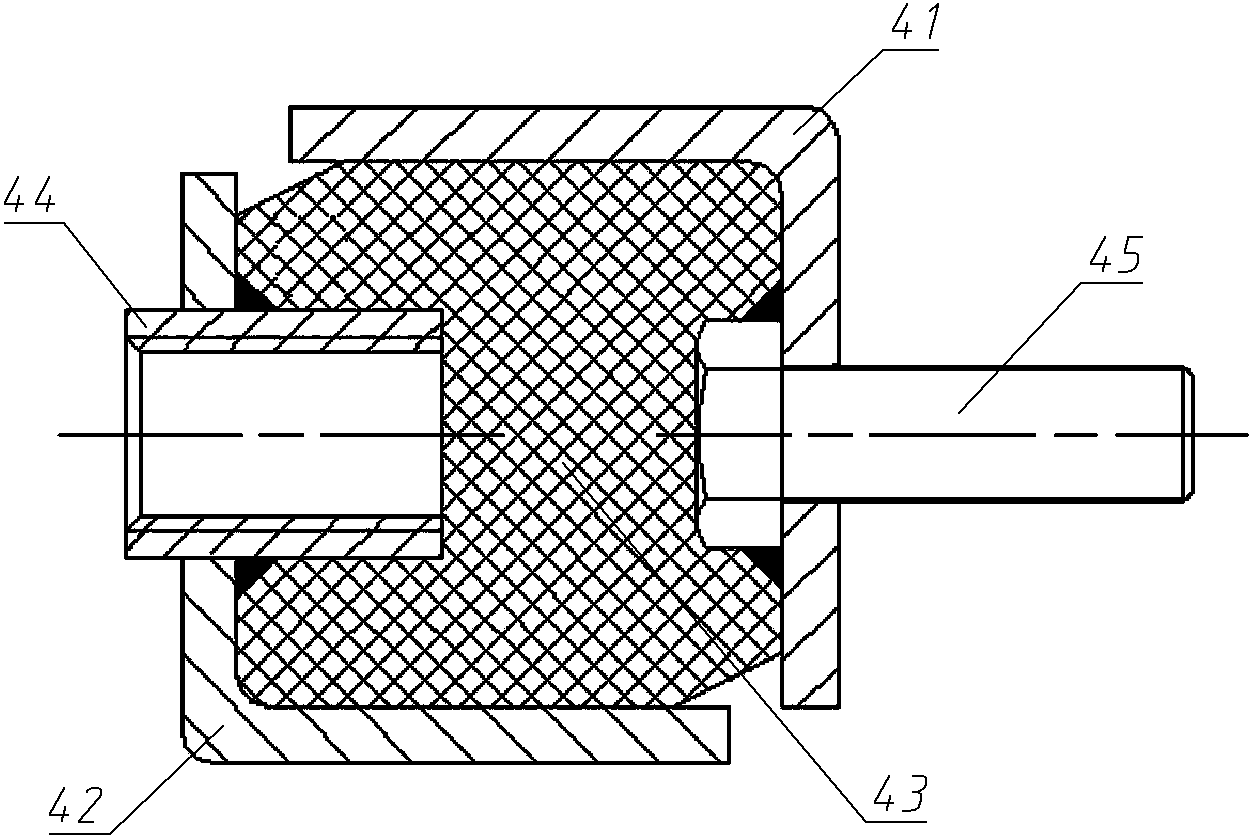

[0021] An example of a vehicle in the present invention is Figure 1~Figure 4 As shown, it is a commercial vehicle with a vibration-absorbing spare tire bracket, including a vehicle frame 10, a spare tire bracket 20 and a spare tire 30, and the spare tire bracket 20 includes a lifter main body 21, a lower pallet 22, a rocker 23 and a lift Rope, the spare tire 30 is connected on the lower supporting plate 22 of the spare tire rack 20, and the lower supporting plate 22 and the spare tire 30 can be driven up and down by shaking the rocker 23 through the lifting rope, so that the spare tire 30 can be put away and put down. 30 can be fixed together with spare tire frame 20 when packing up. The above-mentioned lifting method of the spare tire 30 is a commonly used prior art, and the structures of the lifter main body 21, the lower supporting plate 22, the rocking bar 23 and the lifting rope will not be described in detail here.

[0022] The vehicle frame 10 includes a longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com