Electromagnetic braking device for elevator hoister

A technology of electromagnetic brake and winch, which is applied in the direction of winch device, etc., can solve the problems such as the impact of the room, and achieve the effect of improving stability and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

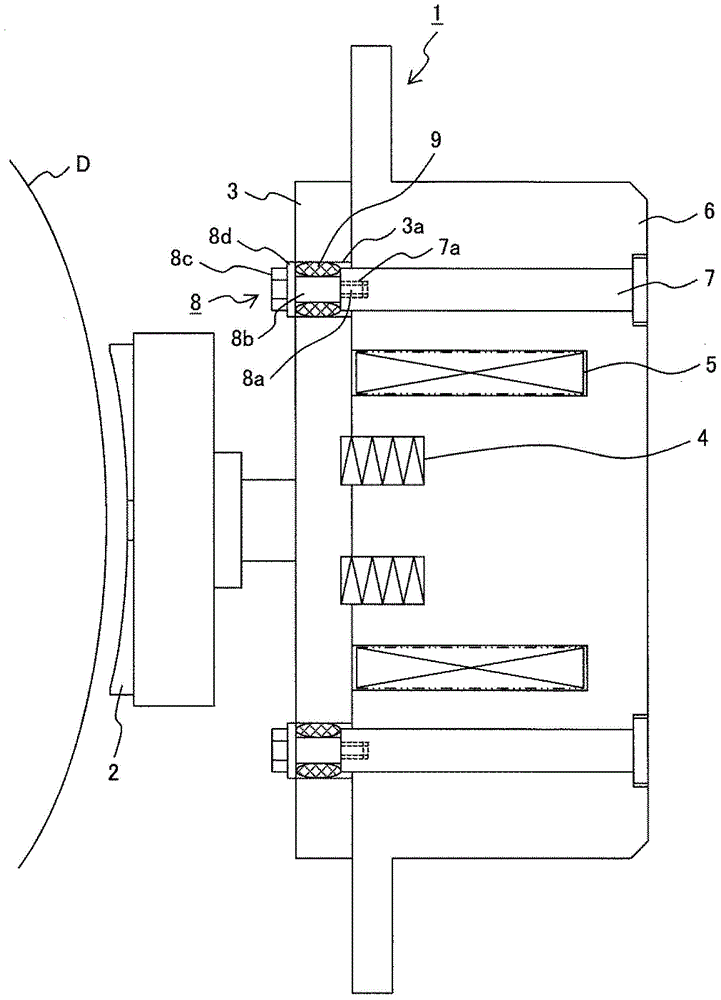

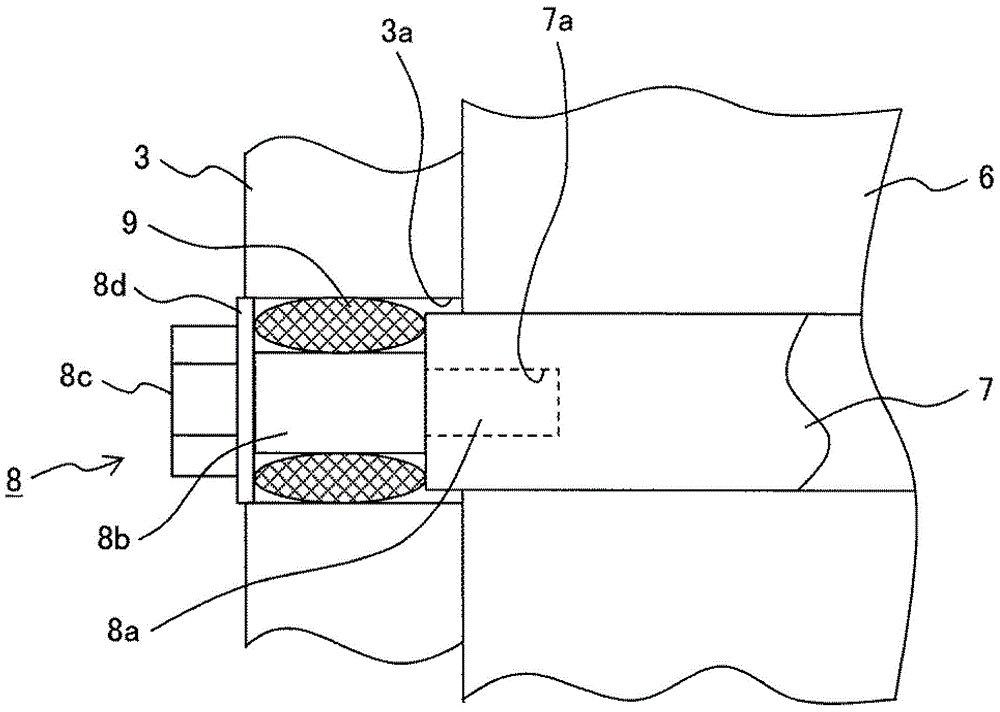

[0028] figure 1 It is a sectional view showing the electromagnetic brake device according to the first embodiment of the present invention. figure 2 yes figure 1 enlarged sectional view of the .

[0029] The installation purpose of the electromagnetic braking device 1 is, for example, to brake the lifting body of an elevator. Such as figure 1 As shown, there are brake shoes 2 capable of sliding contact with the brake drum of the hoist, an armature 3 supporting the brake shoe 2, a brake spring 4 that presses the armature 3 to push the brake shoe 2 in the braking direction, The electromagnet core 6 and the rod 7, the electromagnet core 6 has the electromagnetic winding 5, which overcomes the pushing force of the brake spring 4 and attracts the armature 3, so that the brake shoe 2 leaves the brake drum, and the rod 7 is integrally arranged on the electromagnetic Iron core 6 to guide the displacement of armature 3.

[0030] In the electromagnetic braking device 1 of the firs...

no. 2 example

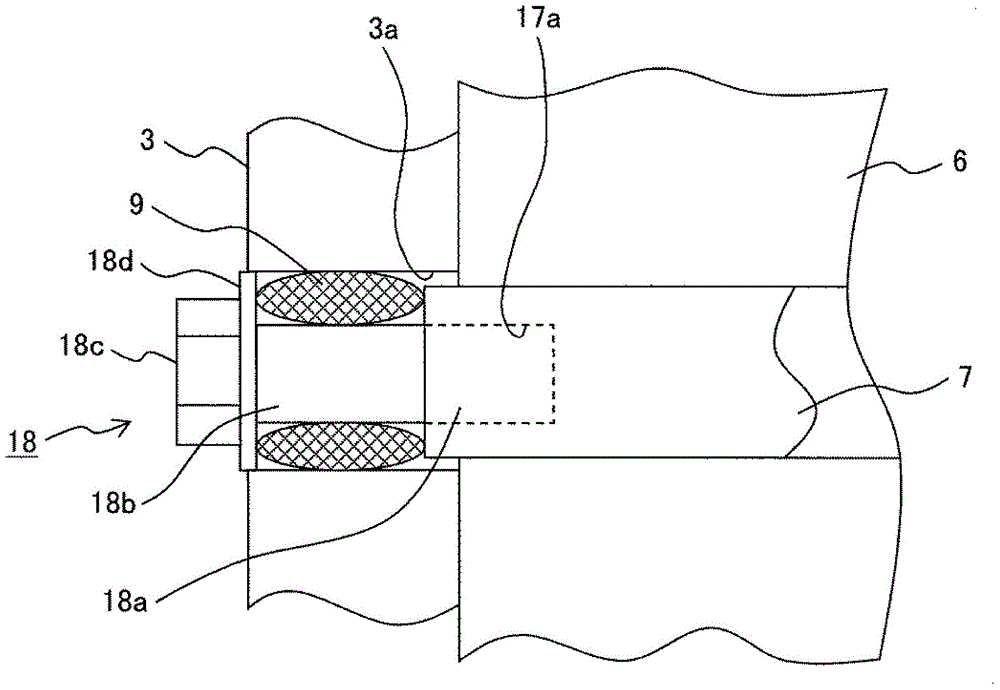

[0040] image 3 It is a sectional view showing the electromagnetic brake device according to the second embodiment of the present invention. Such as image 3As shown, there is a bolt body 18 that is detachably threadedly fitted to the end of the rod 7 on the brake shoe side, and an elastic body 9 disposed between the bolt body 18 and the armature 3. The elastic body 9 The contact area with the armature 3 can be changed as the screw body 18 advances and retreats.

[0041] A male thread 18 a is formed at the front end of the bolt body 18 , and the male thread 18 a is screwed into a female thread 17 a formed on the rod 7 . In addition, the diameter of the middle part 18b of the bolt body 18 is smaller than the diameter of the guide hole 3a formed on the armature 3, and has a width larger in diameter than the middle part 18b and slightly smaller than the guide hole 3a on the head 18c side. Section 18d. The elastic body 9 is formed of a rubber ring having an oval shape in cross...

no. 3 example

[0043] Figure 4 It is a sectional view showing the electromagnetic brake device according to the third embodiment of the present invention. Such as Figure 4 As shown, it is equipped with a bolt body 28 that is detachably screwed to the end portion of the rod 7 on the brake shoe side, and an elastic body 9 disposed between the bolt body 28 and the armature 3. The elastic body 9 The contact area with the armature 3 can be changed as the screw body 28 advances and retreats. Reference numeral 26 denotes an electromagnet core.

[0044] The front end of the bolt body 28 is formed with a male thread 28a, and the male thread 28a is threadedly engaged with a female thread 27a formed on the rod member 7 . In addition, the diameter of the middle portion 28b of the bolt body 28 is smaller than the diameter of the guide hole 3a formed on the armature 3, and has a wider portion on the head 28c side with a diameter larger than the middle portion 28b and slightly smaller than the guide h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com