Denitrated uranium trioxide hydration and activation technology

A technology of uranium trioxide and denitrification, which is applied in the field of uranium conversion, can solve problems such as unapplied examples and complicated process, and achieve the effect of simple equipment, simple system structure and feasible process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

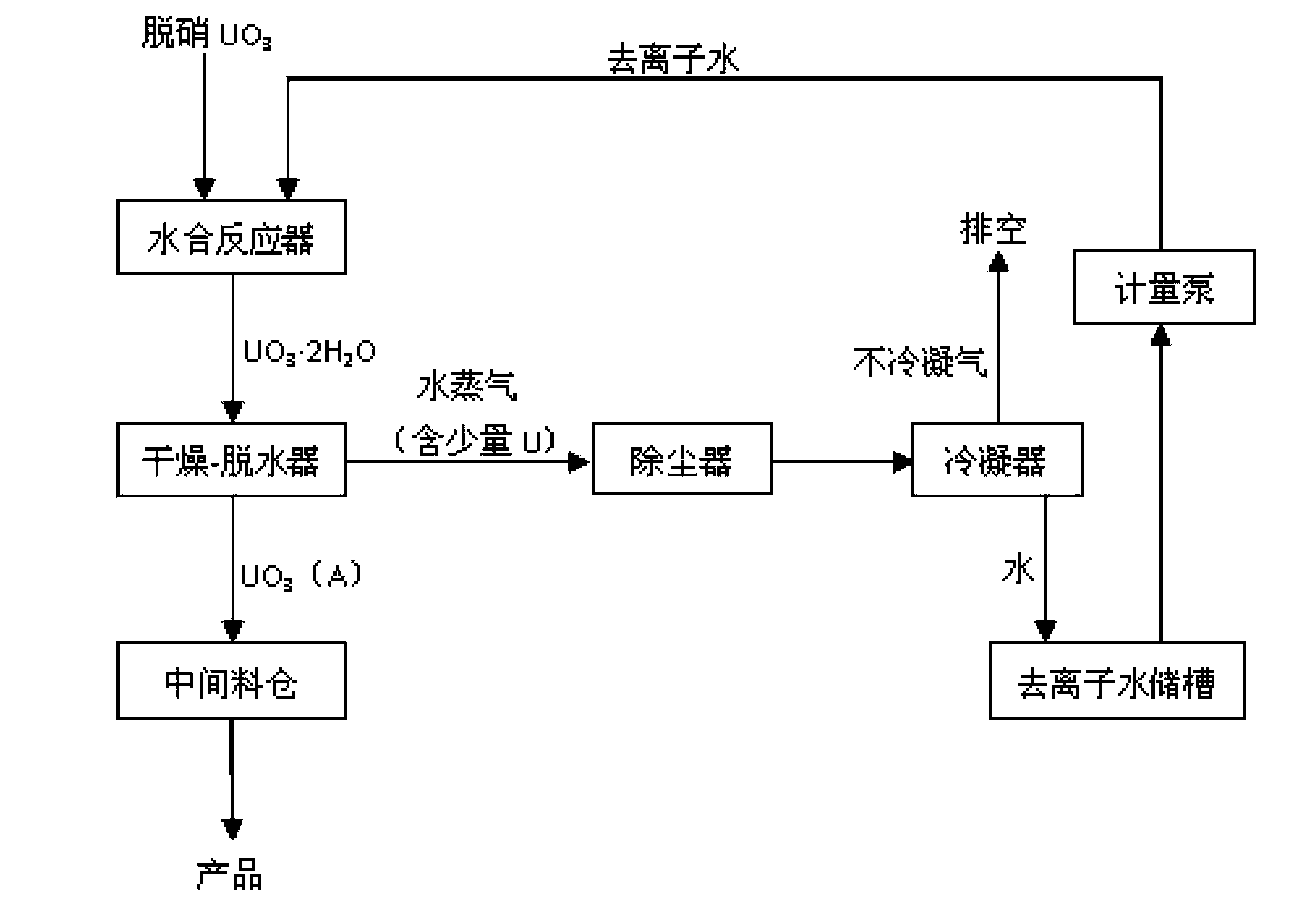

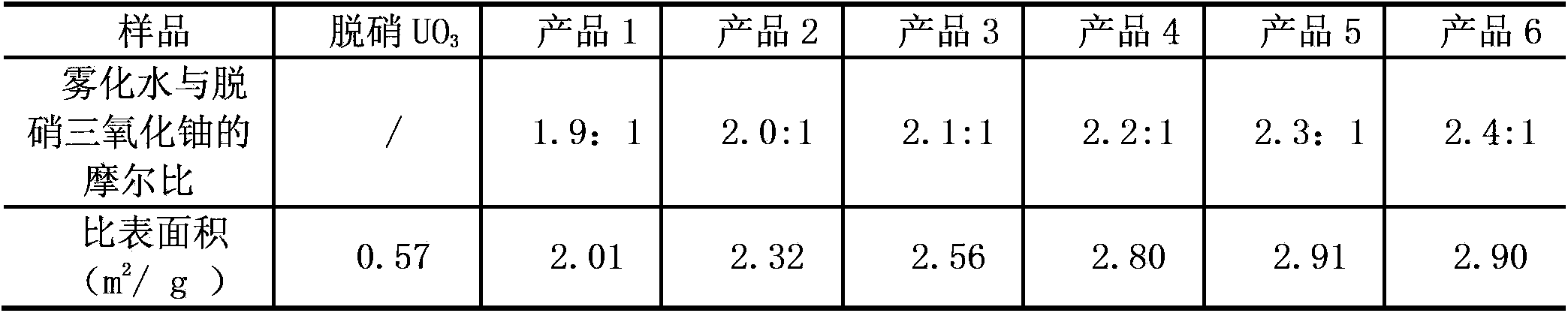

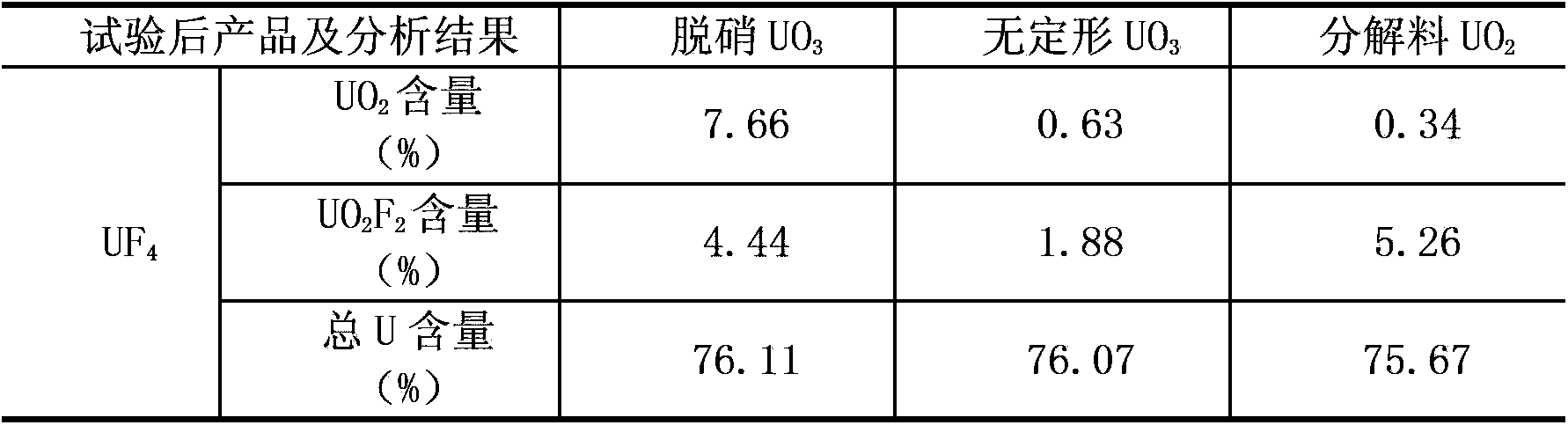

[0027] The principle of the present invention is: denitrification UO 3 Under certain conditions, react with water to form UO 3 2H 2 O, UO 3 2H 2 O can form amorphous UO after drying-dehydration 3 . According to this feature, the present invention uses the horizontal stirred bed as the hydration reactor, by controlling the flow of atomized water, UO 3The input amount and the temperature of the reactor, the hydration reaction is carried out in the reactor to generate UO 3 2H 2 O, then to UO 3 2H 2 O, for drying-dehydration, the drying dehydrator also adopts the horizontal stirring bed method, which is realized by controlling the temperature.

[0028] A denitration uranium trioxide hydration activation process, such as figure 1 shown, including the following steps:

[0029] Step 1, build the hydration activation test platform: the test system f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com