Weaving method of seamless underwear fabrics

A kind of underwear fabric, seamless technology, applied in underwear, weft knitting, knitting, etc., can solve the problem of not being able to have both cold resistance and air permeability, and achieve the effect of light and thin material and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Choose two looms to use at the same time, the first loom has a cylinder diameter of 12 inches, the number of needles is 720 needles, and the number of stages is 19G; the second loom has a cylinder diameter of 6 inches, the number of needles is 300 needles, and the stage The number is 16G,

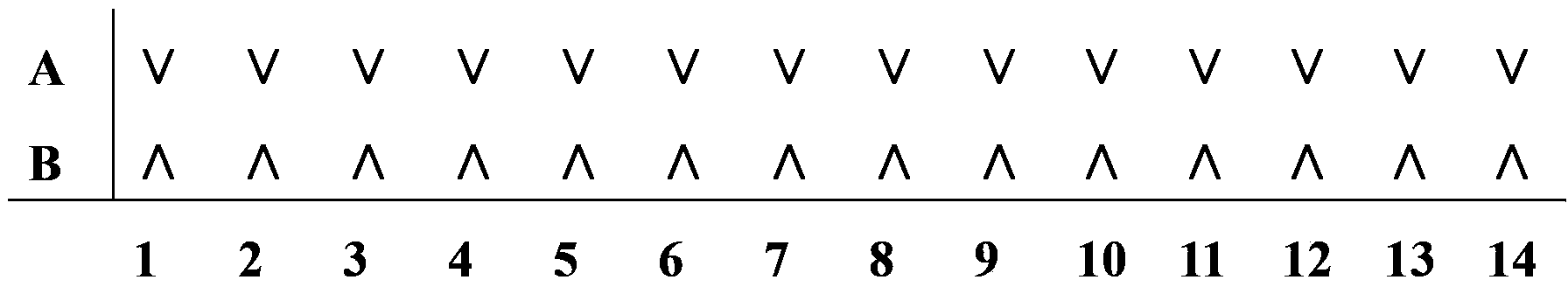

[0020] When knitting, a) determine the manual needle arrangement method, the knitting needles are arranged according to AB, the material used for A knitting needles is acrylic fiber, its fineness is 32 pieces / 1, and its consumption is 96% of the total fiber weight, and the knitting needles used for B are The material is a mixed fiber of spandex and nylon, wherein the fineness of spandex is 18D, and the dosage is 1% of the total fiber mass, and the fineness of nylon is 12D, and the dosage is 3% of the total fiber weight.

[0021] b) Determine the weaving mode, weaving 14 roads is a complete loop organization, wherein, the fiber fineness of 1, 3, 5, 7, 9, 11, 13 roads is 32, 2, 4, 6, 8...

Embodiment 2

[0023] Choose two looms to use at the same time, the first loom has a cylinder diameter of 12 inches, the number of needles is 720 needles, and the number of stages is 19G; the second loom has a cylinder diameter of 6 inches, the number of needles is 300 needles, and the stage The number is 16G,

[0024] When weaving, a) determine the way of manual arrangement of needles, the knitting needles are arranged according to AB, the material used for A knitting needles is the mixed fiber of spandex and nylon, wherein the fineness of acrylic fiber is 32, and its consumption is 96% of the total weight of the fiber, The fineness of spandex is 18D, and its dosage is 1% of the total weight of the fiber. The material used for the B knitting needle is acrylic fiber, and its fineness is 28, and the dosage is 96% of the total fiber mass. The fineness of nylon is 12D, and the dosage is 3% of the total fiber weight.

[0025] b) Determine the weaving method, weaving 14 roads is a complete loop ...

Embodiment 3

[0027] Choose two kinds of looms to use at the same time. The cylinder diameter of the first loom is 12 inches, the number of needles is 720 needles, and the number of stages is 19G. The diameter of the second loom is 6 inches, and the number of needles is 300 needles. The number is 16G,

[0028] When knitting, a) determine the manual needle arrangement method, the knitting needles are arranged according to AB, the material used for A knitting needles is acrylic fiber, its fineness is 28, and its consumption is 90% of the total weight of fibers, and the material used for B knitting needles is The mixed fiber of spandex and nylon, the spandex fineness is 40D, the dosage is 5% of the total fiber mass, the nylon fineness is 150D, and the dosage is 5% of the total fiber weight.

[0029] b) Determine the weaving method, weaving 14 roads is a complete loop organization, wherein, the fiber fineness of 1, 3, 5, 7, 9, 11, 13 roads is 25D, 2, 4, 6, 8, 10, 12, The fiber fineness of 14 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com