Good tensile performance, environmental protection, spray-paintable, weather-resistant and personalized car sticker production process

A production process and car sticker technology, applied in metal processing, thin material handling, transportation and packaging, etc., can solve the problems of loss of stretchability, high storage requirements, easy quality change, etc., and achieve easy degradation, good tensile properties, Store convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

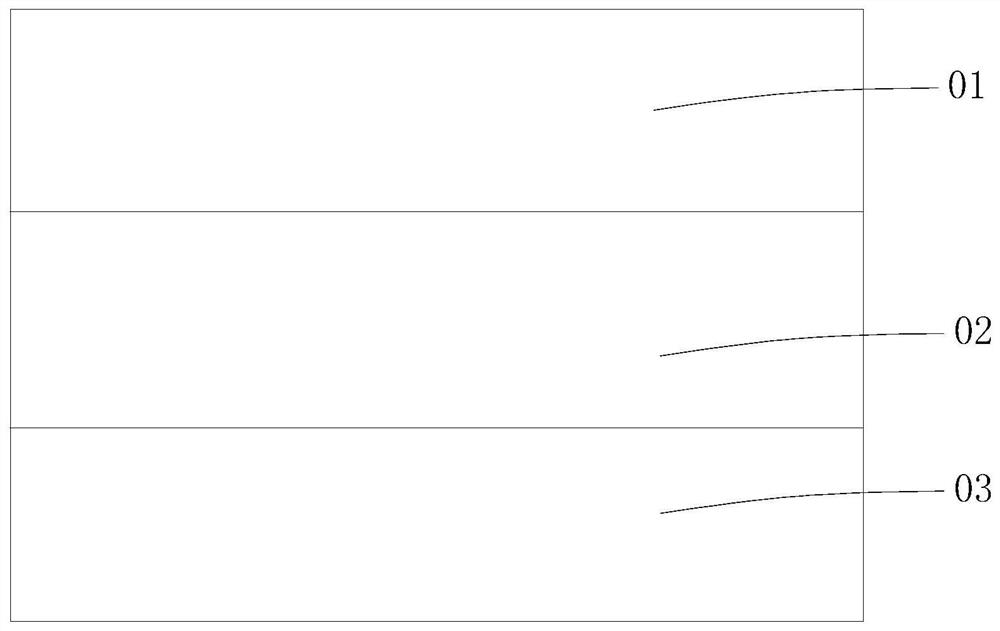

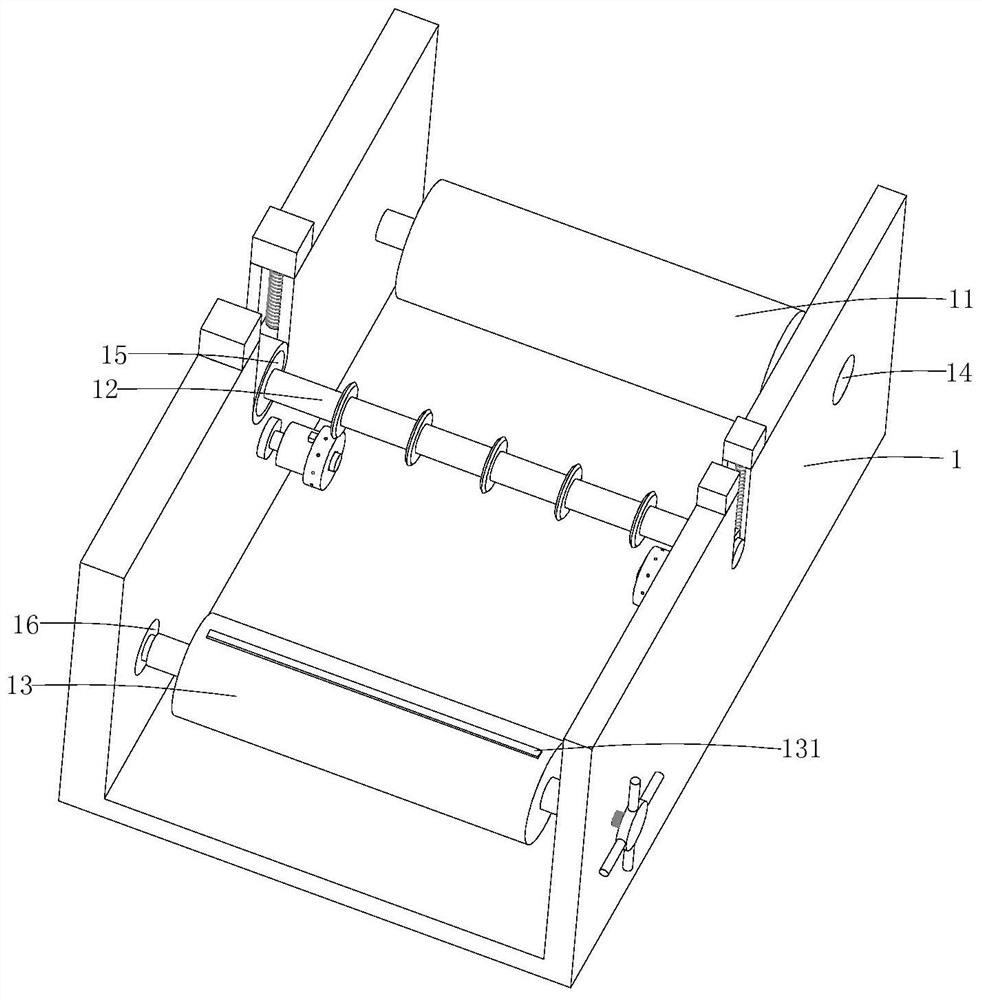

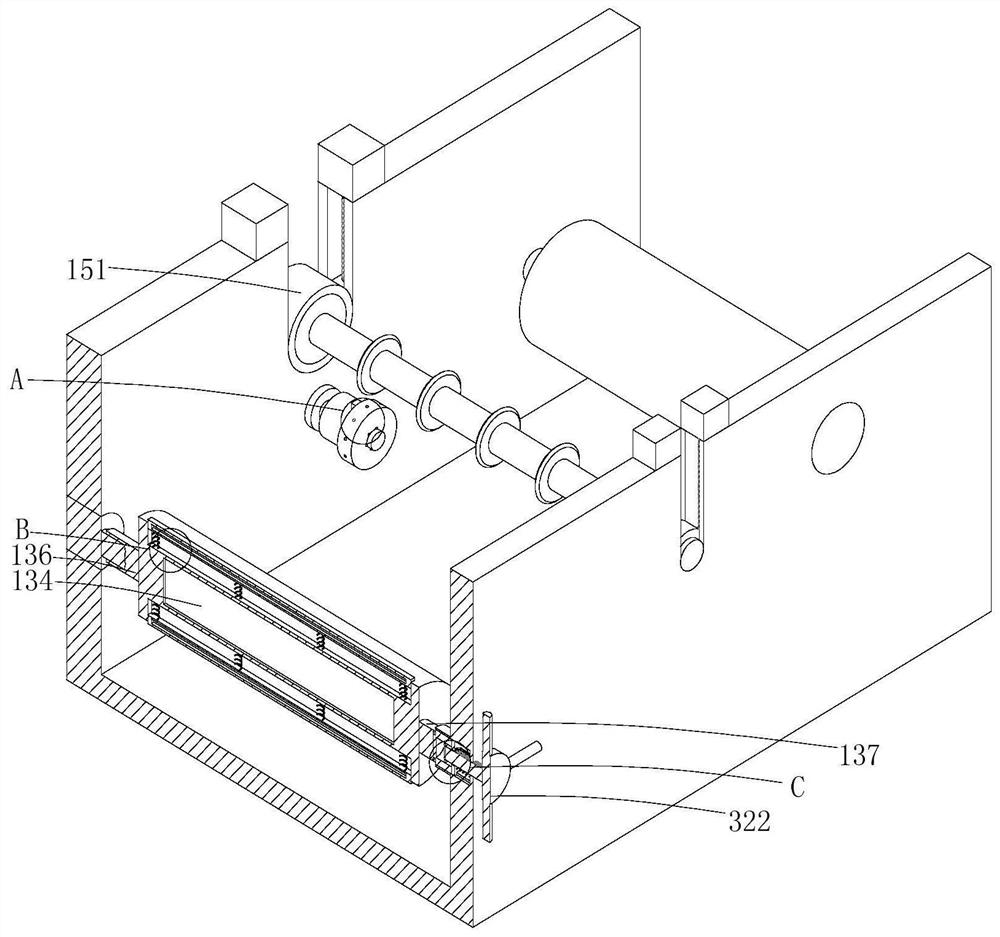

[0023] A production process of environmentally friendly and stretchable personalized car stickers that can be printed and weather-resistant. The personalized car stickers that can be printed and weather-resistant with good environmental protection stretching properties include 5-wire PVCfree material 01, polymer adhesive layer 02 and 140g double-plastic G paper Release material 03, the production process of the environmentally friendly and weather-resistant personalized car stickers with good tensile properties can include the following steps: a. base paper: prepare the base paper to be used; b. printing: print the specified personalized pattern on the base paper ; c. Lamination: Laminate film on the base paper; d. Die-cutting of release paper: Cut the release paper to the specifications suitable for the base paper through the die-cutting equipment of release paper; The paper and the adhesive layer are extruded and bonded together; in the step a, the paper of more than 125g / m2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com