Novel sound absorption material and structure for vehicle and manufacturing method thereof

A technology for sound-absorbing materials and vehicles, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve the problems of single application frequency range, difficult to master the preparation process, poor sound absorption effect, etc., and achieve excellent sound absorption effect, low production cost, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

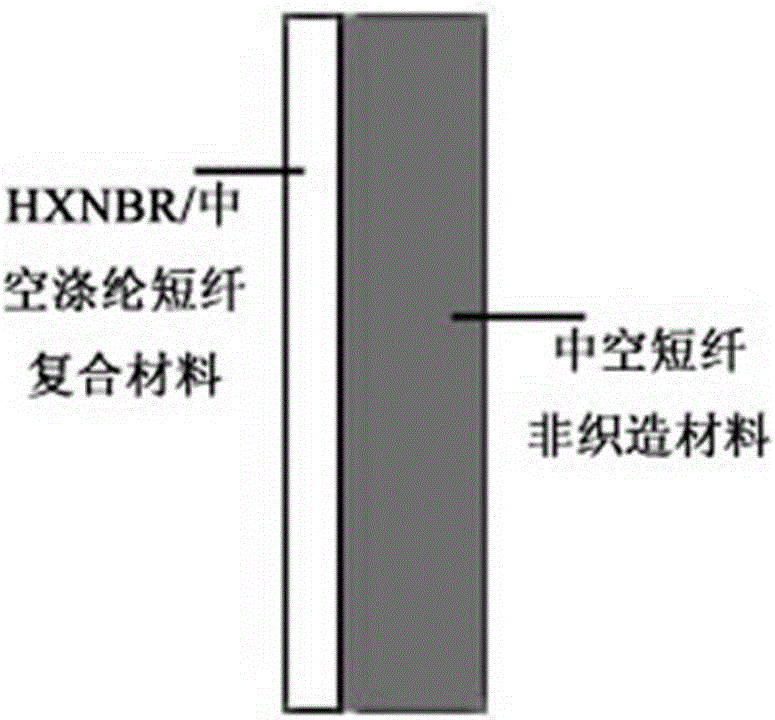

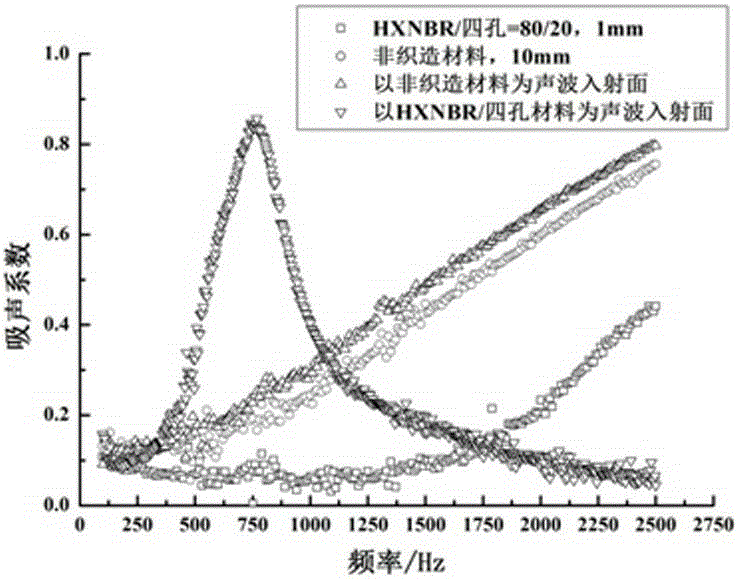

[0025] HXNBR and four-hole hollow polyester staple fiber are weighed according to the mass ratio of 80 / 20. First, HXNBR is kneaded on a double-roll mill at 30±5°C for 5 minutes to form a film with a relatively uniform thickness. Then add a certain amount of four-hole hollow polyester staple fiber to the film, lay it evenly, then fold the film to wrap the fiber inside, and then knead for 3 to 5 minutes, repeat this process until the weighed four Hollow polyester staple fiber is completely added and mixed evenly to obtain a HXNBR / four-hole hollow polyester staple fiber mixture; put the HXNBR / four-hole hollow polyester staple fiber mixture into a 1mm thick mold, and the upper and lower parts of the mold are 30cm×30cm thick The 3mm stainless steel plate is clamped, and a layer of anti-sticking high-temperature resistant PET film is placed between the mold and the steel plate, and then the installed steel plate is placed in a flat vulcanizer, preheated at 130°C for 5 minutes, and th...

Embodiment 2

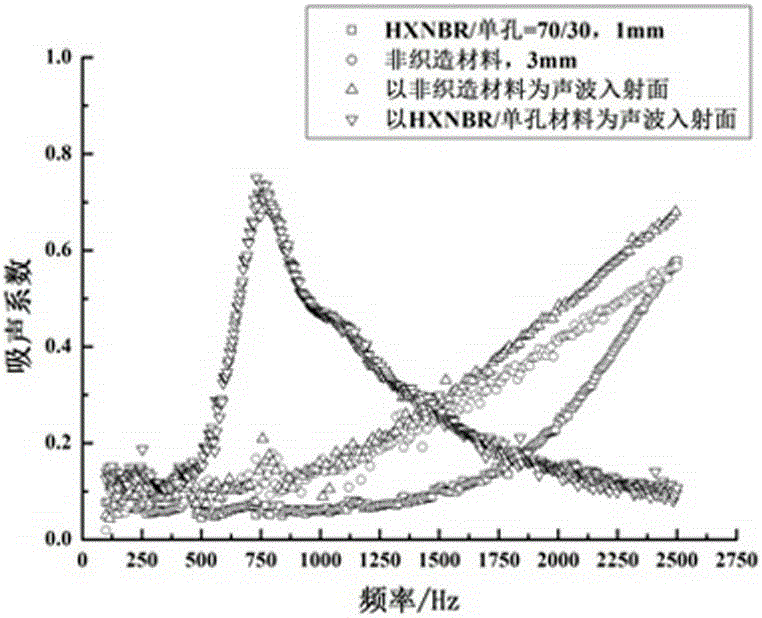

[0028] HXNBR and single-hole hollow polyester staple fiber are weighed according to the mass ratio of 70 / 30. First, HXNBR is kneaded on a double-roll mill at 30±5°C for 5 minutes to form a film with a relatively uniform thickness. Then add a certain amount of single-hole hollow polyester staple fiber to the film, lay it evenly, then fold the film to wrap the fiber inside, and then knead for 3 to 5 minutes, repeat this process until the weighed single The hollow polyester staple fiber is completely added and mixed evenly to obtain the HXNBR / single-hole hollow polyester staple fiber mixture; put the HXNBR / single-hole hollow polyester staple fiber mixture into a 1mm thick mold, and the upper and lower parts of the mold are 30cm×30cm thick The 3mm stainless steel plate is clamped, and a layer of anti-sticking and high-temperature resistant PET film is placed between the mold and the steel plate, and then the installed steel plate is placed in a flat vulcanizer, preheated at 130°C f...

Embodiment 3

[0031] HXNBR and seven-hole hollow polyester staple fiber were weighed according to the mass ratio of 70 / 30. First, HXNBR was kneaded on a double-roll mill at 30±5°C for 5 minutes to form a film with a relatively uniform thickness. Then add a certain amount of seven-hole hollow polyester staple fiber to the film, lay it evenly, then fold the film to wrap the fiber inside, and then knead for 3 to 5 minutes, repeat this process until the weighed seven The hollow polyester staple fiber is completely added and mixed evenly to obtain the HXNBR / seven-hole hollow polyester staple fiber mixture; the HXNBR / seven-hole hollow polyester staple fiber mixture is put into a 1mm thick mold, and the mold is 30cm×30cm thick. The 3mm stainless steel plate is clamped, and a layer of anti-sticking and high-temperature resistant PET film is placed between the mold and the steel plate, and then the installed steel plate is placed in a flat vulcanizer, preheated at 130°C for 10 minutes, and then adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com