A kind of nano silver microsphere emulsion and its preparation method and application

A nano-silver and nano-silver sol technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of wide particle size distribution, insufficient long-term effect, and easy agglomeration of nano-silver. effect of effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

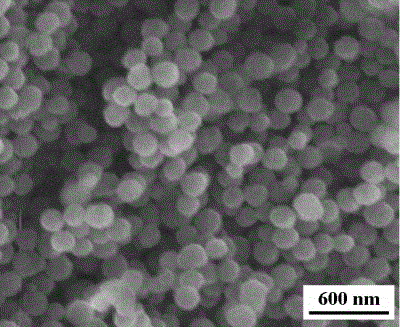

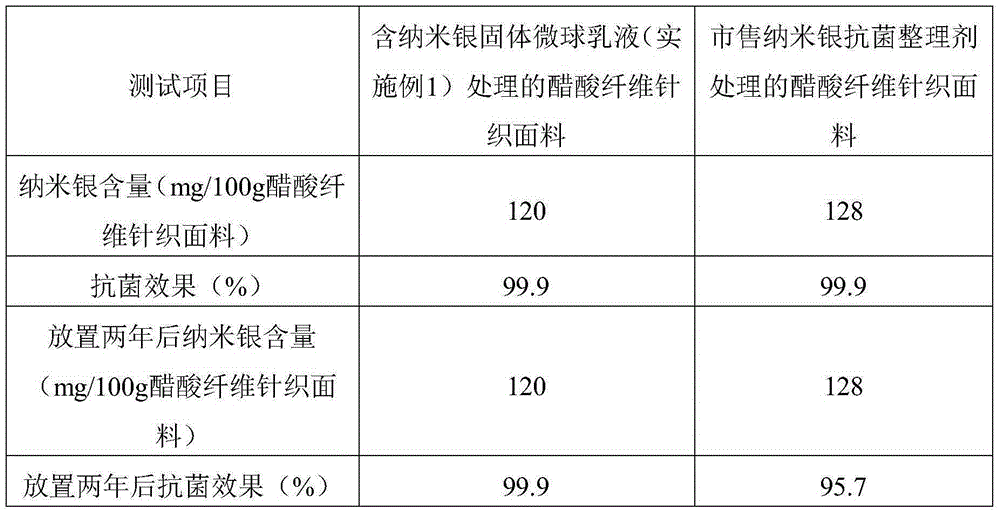

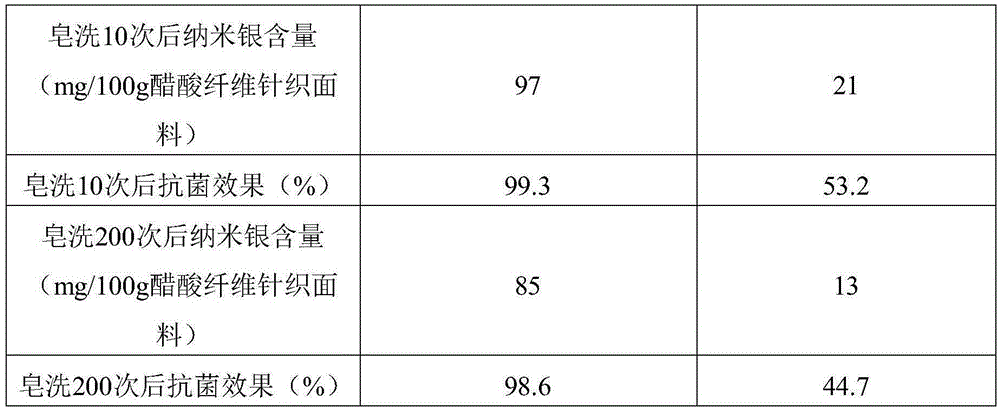

[0033] 4g PluronicF-127 (CAS: 9003-11-6, purchased from Sigma Company, molecular formula is HO(C2 h 4 O) 100 (C 3 h 6 O) 65 (C 2 h 4 O) 100 H) adding to 1000mL deionized water, stirring at a rate of 200rpm at 0°C until completely dissolved, then adding 2g of silver nitrate, and stirring at a rate of 800rpm for 1h at 45°C to obtain nano-silver sol microspheres with good water dispersibility,- Freeze-drying at 80° C. to obtain dry powder of nano-silver sol microspheres.

[0034] At 0°C, spread 1g of nano-silver sol microsphere dry powder on the vibrating conveyor belt, and at 100°C, use a melt sprayer to melt paraffin (section paraffin, pathological grade, melting point: 60-62°C) and spray it on the nano-silver sol Microsphere dry powder coating, the spray parameter is 10mg / min·cm 2 , the residence time of the nano-silver sol microsphere dry powder in the melt spray area is 1 second, and then immediately cooled to 0°C; through 2 sprays, the cladding thickness is 20±2nm, ...

Embodiment 2

[0038] 4g PluronicF-127 (CAS: 9003-11-6, purchased from Sigma Company, molecular formula is HO(C 2 h 4 O) 100 (C 3 h 6 O) 65 (C 2 h 4 O) 100 H) added to 1000mL deionized water, stirred at a rate of 300rpm at 10°C until completely dissolved, then added 1.8g of silver nitrate, stirred at a rate of 700rpm at 35°C for 2h, to obtain nano-silver sol microspheres with good water dispersibility, Freeze-drying at -60°C to obtain dry powder of nano-silver sol microspheres.

[0039] At 10°C, spread 1g of nano-silver sol microsphere dry powder on the vibrating conveyor belt, and at 95°C, use a melt sprayer to melt paraffin (section paraffin, pathological grade, melting point: 60-62°C) and spray it on the nano-silver sol Microsphere dry powder coating, the spray parameter is 10mg / min·cm 2 , The residence time of nano-silver sol microspheres dry powder in the melt spray area is 0.5 seconds, and then immediately cooled to 0 ° C; through 2 sprays, the coating thickness is 21 ± 2nm, a...

Embodiment 3

[0042] 4g PluronicF-127 (CAS: 9003-11-6, purchased from Sigma Company, molecular formula is HO(C 2 h 4 O) 100 (C 3 h 6 O) 65 (C 2 h 4 O) 100 H) adding to 1000mL deionized water, stirring at a rate of 400rpm at 20°C until completely dissolved, then adding 1.6g of silver nitrate, stirring at a rate of 600rpm for 3h at 25°C, to obtain nano-silver sol microspheres with good water dispersibility, Freeze-drying at -40°C to obtain dry powder of nano-silver sol microspheres.

[0043] At 20°C, spread 1g of nano-silver sol microsphere dry powder on the vibrating conveyor belt, melt paraffin (section paraffin, pathological grade, melting point 60-62°C) with a melt sprayer at 90°C, and spray it on the nano-silver sol Microsphere dry powder coating, the spray parameter is 10mg / min·cm 2 , The residence time of nano-silver sol microsphere dry powder in the melt spray area is 1 second, and then immediately cooled to 0°C; after 2 sprays, the cladding thickness is 22 ± 2nm, that is, na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com