Bridge hinge joint reinforcing method through transverse anchoring steel plates

A technology of steel plates and hinge joints, which is applied in the reinforcement of bridge hinge joints, can solve the problems of normal traffic influence, high technical requirements, and long time consumption, and achieve the goals of easy construction quality, improved reliability indicators, and improved shear bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

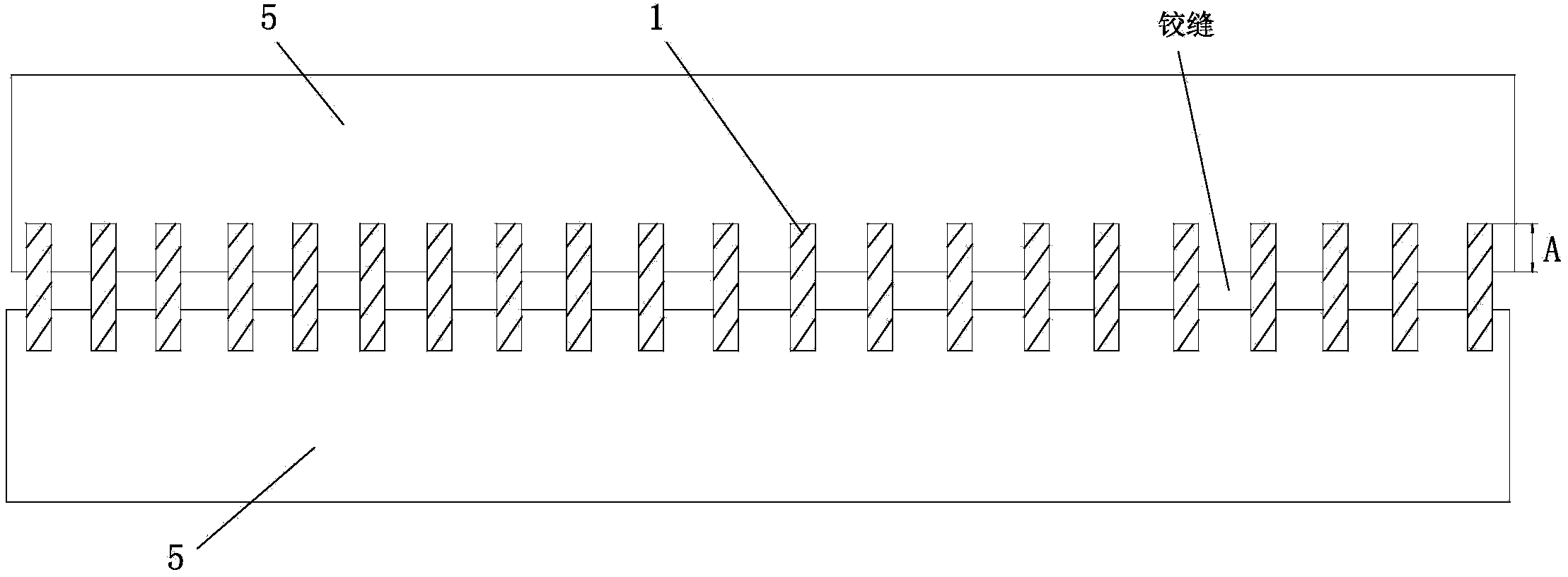

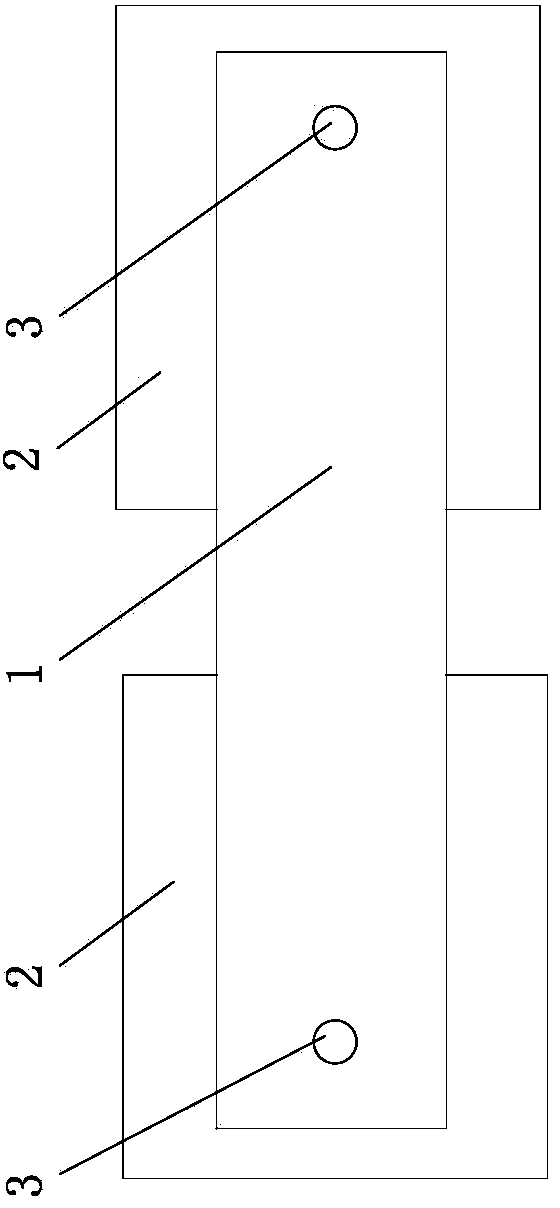

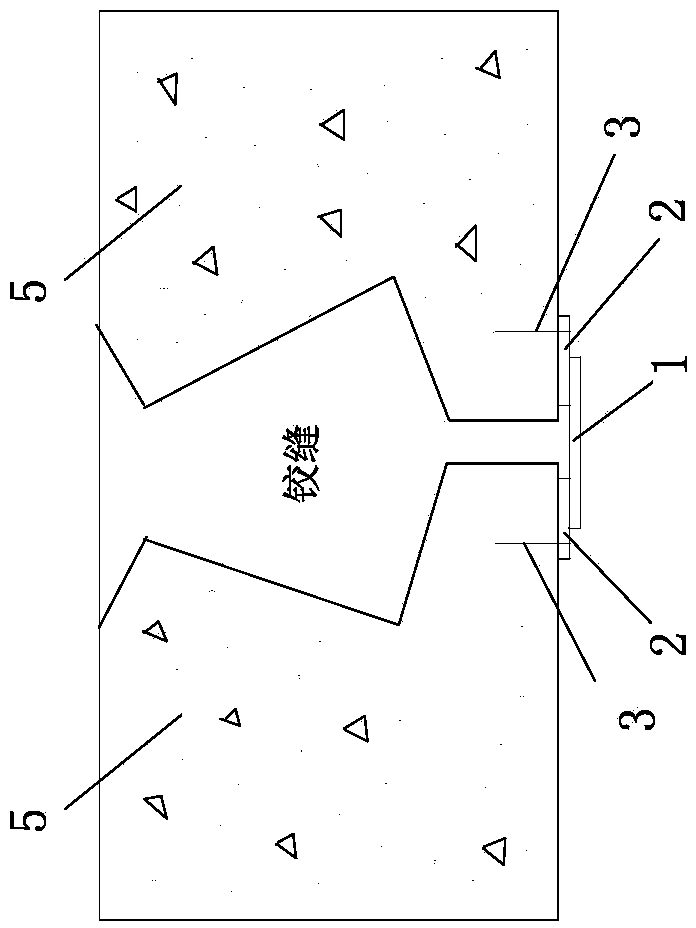

[0018] figure 2 The combined steel plate shown includes a strip-shaped steel plate 1 and two steel backing plates 2; one side of the backing plate is directly attached to the bottom surface of the plate beam 5, and the strip-shaped steel plate is covered on the backing plate, and then respectively bolted 3 (preferably chemical bolts) Fasten the strip steel plate and the backing plate to the plate girder one by one. Due to the use of chemical bolts (purchased), the bolts have the role of anchor rods.

[0019] In order to ensure the connection strength, the bolt fixing part needs to have a certain distance from the edge of the plate girder; for this reason, the distance between the bolt hole and the hinge joint is at least 5 times larger than the bolt hole diameter. Therefore, after the strip-shaped steel plate crosses the hinge joint transversely, the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com