Electro-hydraulic control inverse electromagnetic valve of AT (automatic transmission)

An automatic transmission and electro-hydraulic control technology, which is applied in transmission control, valve details, multi-way valves, etc., can solve the problems of high cost and dependence on imports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

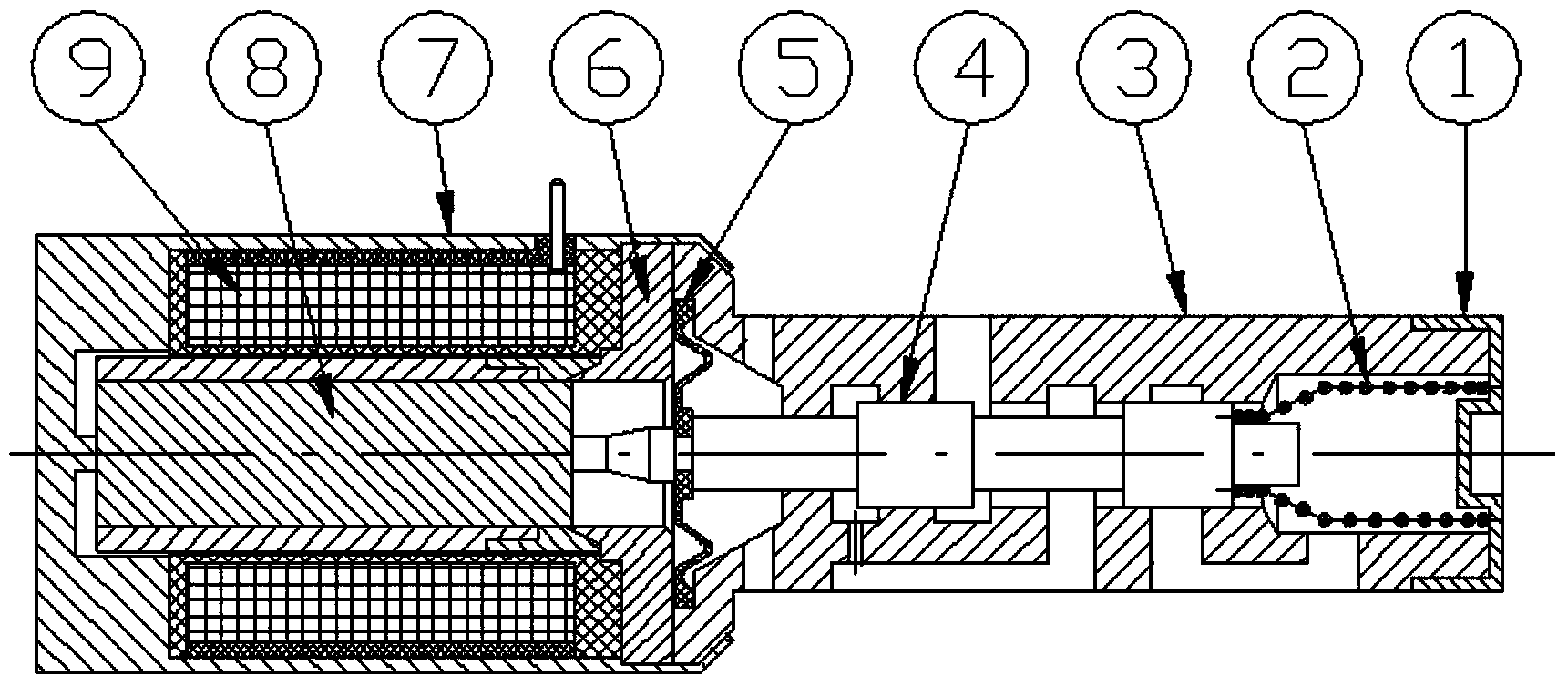

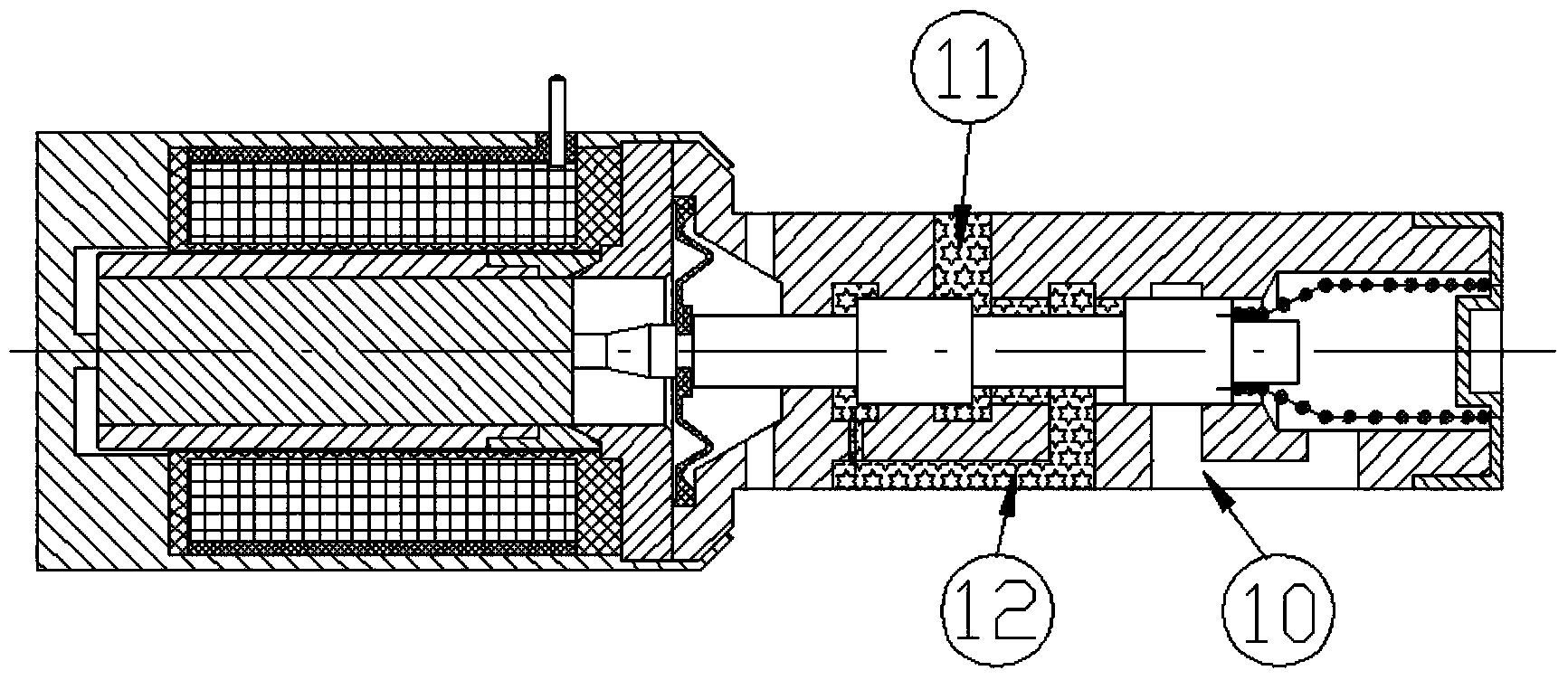

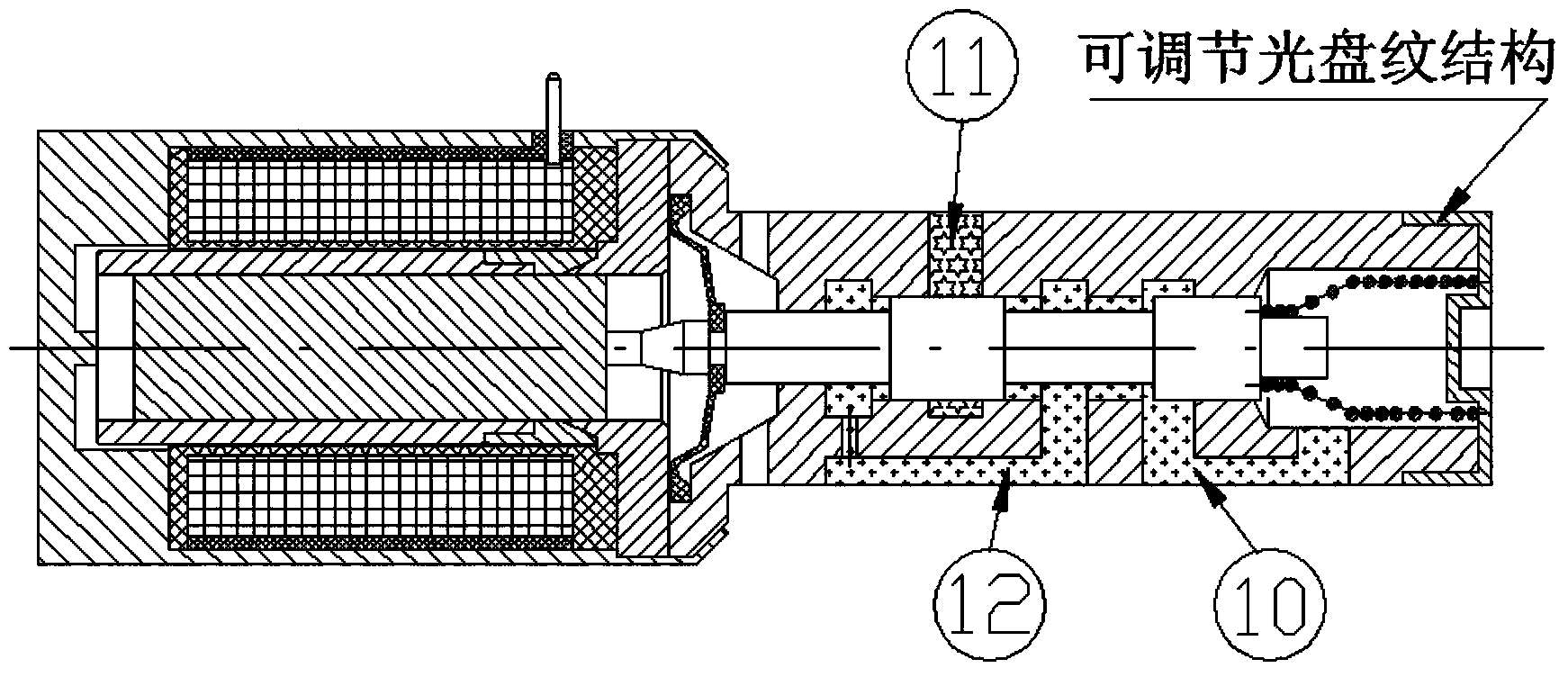

[0015] like figure 1 As shown, the present invention includes a valve body 3, the valve body 3 is hollow tubular with openings at both ends, one end of the valve body 3 is connected to the shell 7, and the other end is connected to the back cover 1, and the inside of the valve body 3 is provided with Open spool 4, one end of the spool 4 is sleeved on one end of the spring 2, the other end of the spring 2 is against the back cover 1, the spring 2 can be squeezed and deformed by the spool 4, and the other end of the spool 4 extends into the shell 7 to resist the armature 8, the armature 8 and the end of the valve core 4 extending into the casing 7 are wrapped inside the yoke assembly 6, and the outside of the yoke assembly 6 is wrapped with a coil 9, and the coil 9 is placed between the casing 7 and the gap between the yoke assembly 6 , The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com