Device for packaging optical fiber grating temperature sensing probe on electric energy meter connecting terminal and integration temperature calibration method thereof

A terminal and fiber grating technology is applied in the field of temperature monitoring of electric energy meters, which can solve the problems of inaccurate temperature measurement and unstable working state, and achieve the effects of improving temperature sensing accuracy, avoiding temperature calibration errors, and avoiding contact damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

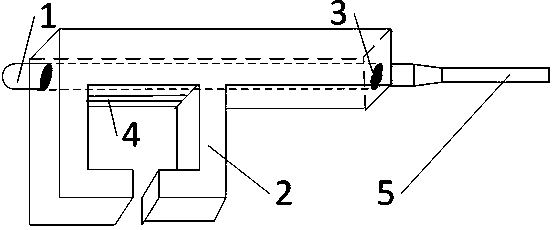

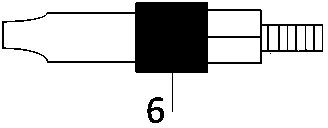

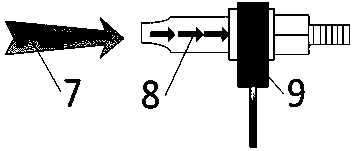

[0021] see figure 1 , a device for encapsulating a fiber grating temperature-sensing probe on an electric energy meter terminal based on a back-shaped card slot structure. The main body of the device is a back-shaped card slot 2 made of a heat-conducting material, and one side of the card slot 2 runs through There is a built-in cylindrical hole for inserting the fiber grating temperature probe, which is used to fix the entire fiber grating temperature probe 1 to the contact of the electric energy meter and can effectively and quickly conduct the heat of the contact. The return type card slot 2 The shape and size of the inner hole correspond to the connection terminals of the electric energy meter. There is a bar-shaped opening area on the inner side of the card slot side that runs through the embedded cylindrical hole 3, and the opening area communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com