Miniature circuit breaker level relative inserting wire inletting structure

A miniature circuit breaker, horizontal technology, applied in the direction of busbar/line layout, protective switch terminal/connection, etc., can solve the problems of confusing wiring, high manufacturing cost, large space occupation, etc., to achieve convenient disassembly and maintenance, ensure electrical conductivity, Guaranteed overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

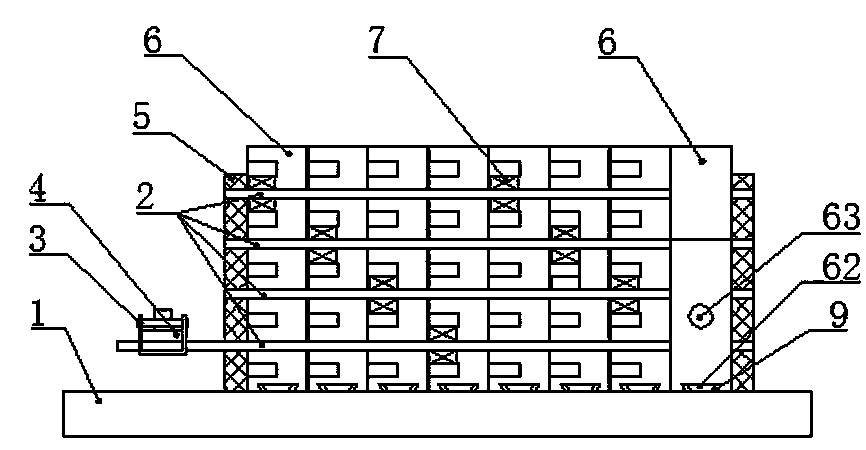

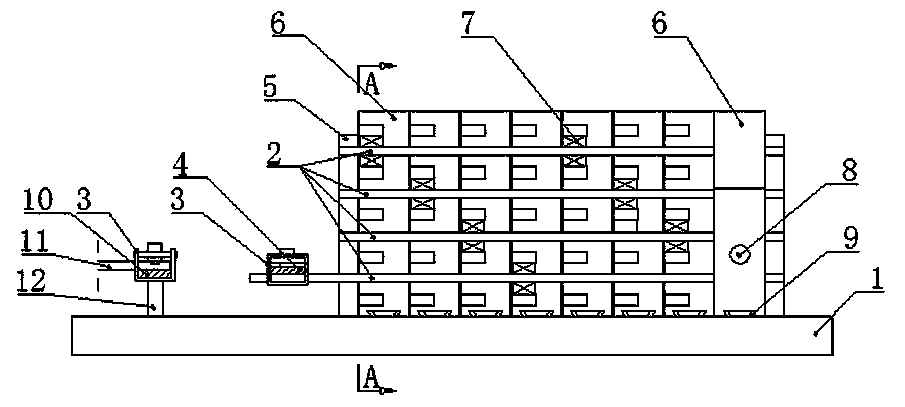

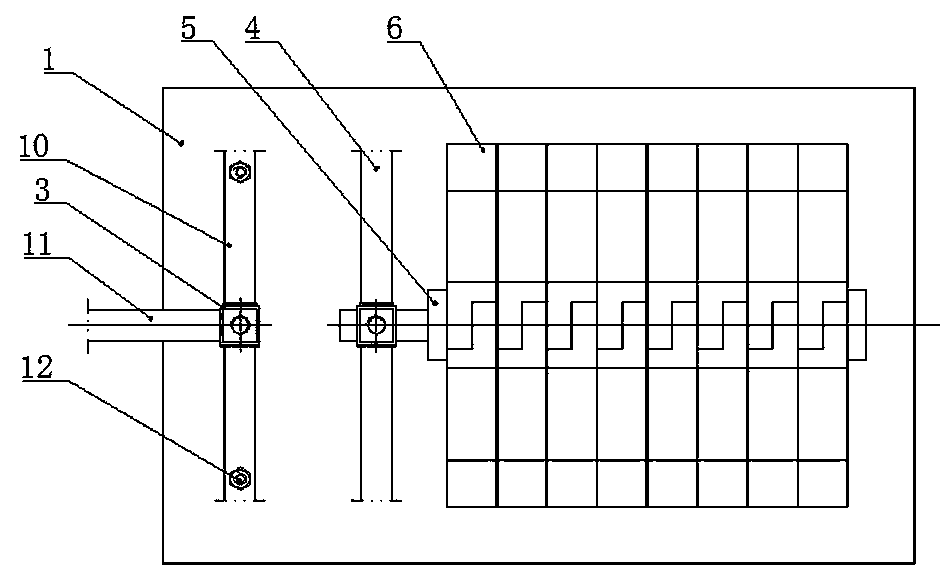

[0043] see Figure 1 to Figure 31 , the present invention is a miniature circuit breaker horizontally relatively inserted into the incoming line structure, including a miniature circuit breaker 6 and a busbar 2, and a plurality of busbars 2 are arranged side by side in multiple layers and fixed on the bottom plate 1 through an insulating bracket 5. The half of one end of the miniature circuit breaker 6 is provided with a plurality of rectangular teeth 61 corresponding to multiple busbars, and in the groove between a certain pair of rectangular teeth 61, there is an insertion port as the incoming line end of the miniature circuit breaker 6 . Type busbar conductive chuck 7, and the other end of the miniature circuit breaker 6 is provided with an outlet terminal 63 (conventional terminal). One end of the rectangular tooth 61 of the paired miniature circuit breaker 6 is plugged on both sides of the busbar 2, and the plug-in busbar conductive clip 7 of each miniature circuit breake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com