A new type of chemical forming equipment

A chemical formation equipment and a new type of technology, applied in the field of lithium-ion batteries, can solve the problems that the battery capacity, cycle performance and high temperature performance cannot be fully exerted, affect product performance, and poor formation effect, etc., and achieve simple structure, ensure formation effect, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

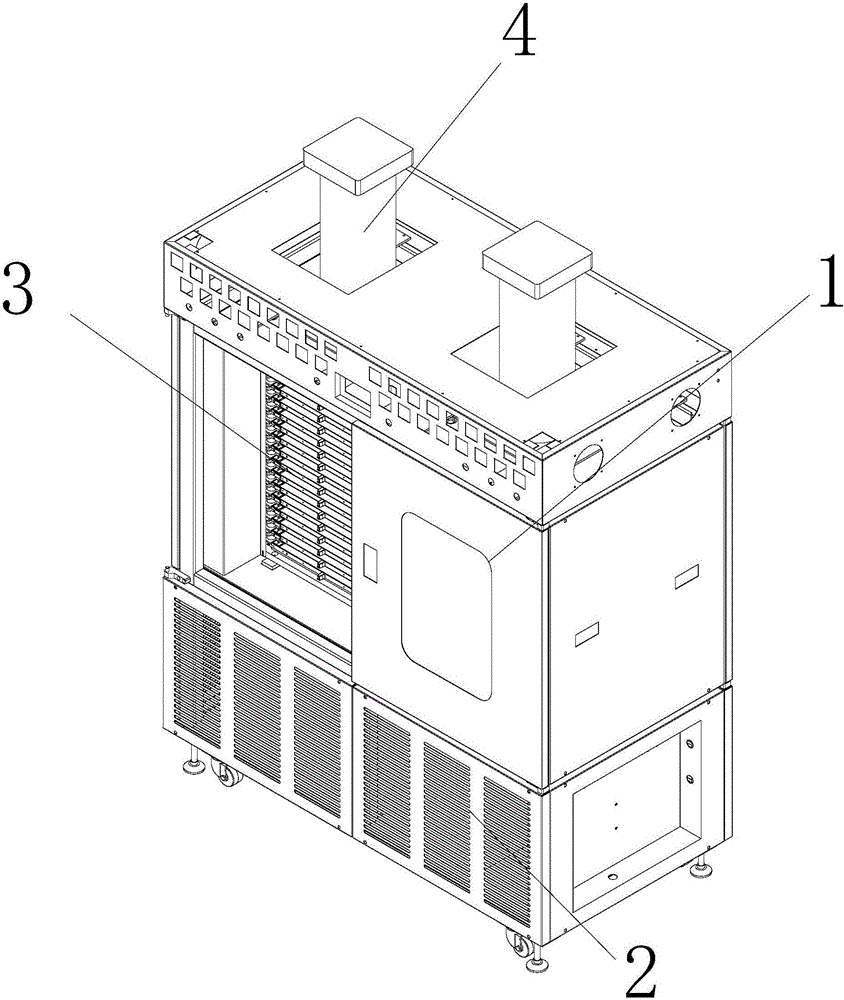

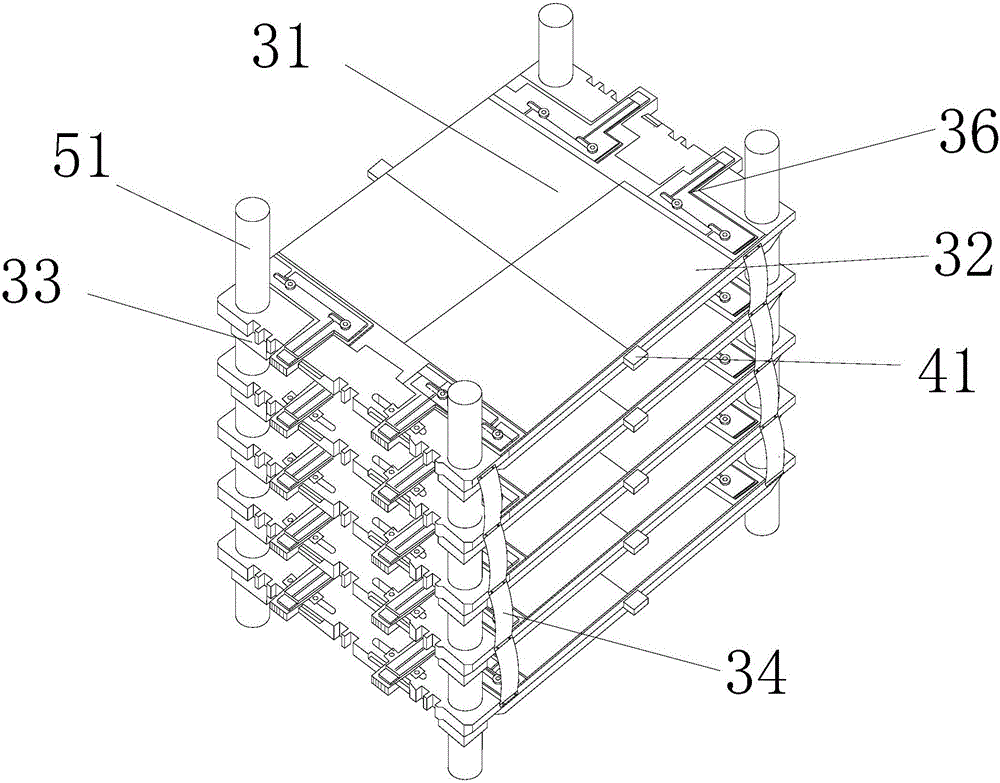

[0038] Figure 1 to Figure 7 A novel chemical formation plant according to the present invention is schematically shown.

[0039] According to one aspect of the present invention, a new type of chemical conversion equipment is provided, including a fixture 3, a chassis 1, a power supply 2, and a lifting mechanism and a heating unit for the fixture 3, wherein

[0040] The above-mentioned lifting mechanism includes four sets of movable shafts 51 and cylinders 4 arranged in the cabinet 1. The cylinder 4 is fixed on the cabinet 1 and its output shaft is connected with the pressure block provided. The cylinder 4 can adjust the clamp 3 as required. Provide pressure, the heating part heats the soft-packed lithium-ion battery, the heating temperature and the applied pressure can be set, and the pressure is 0-15kgf / cm 2 , the heating temperature is from room temperature to 90°C.

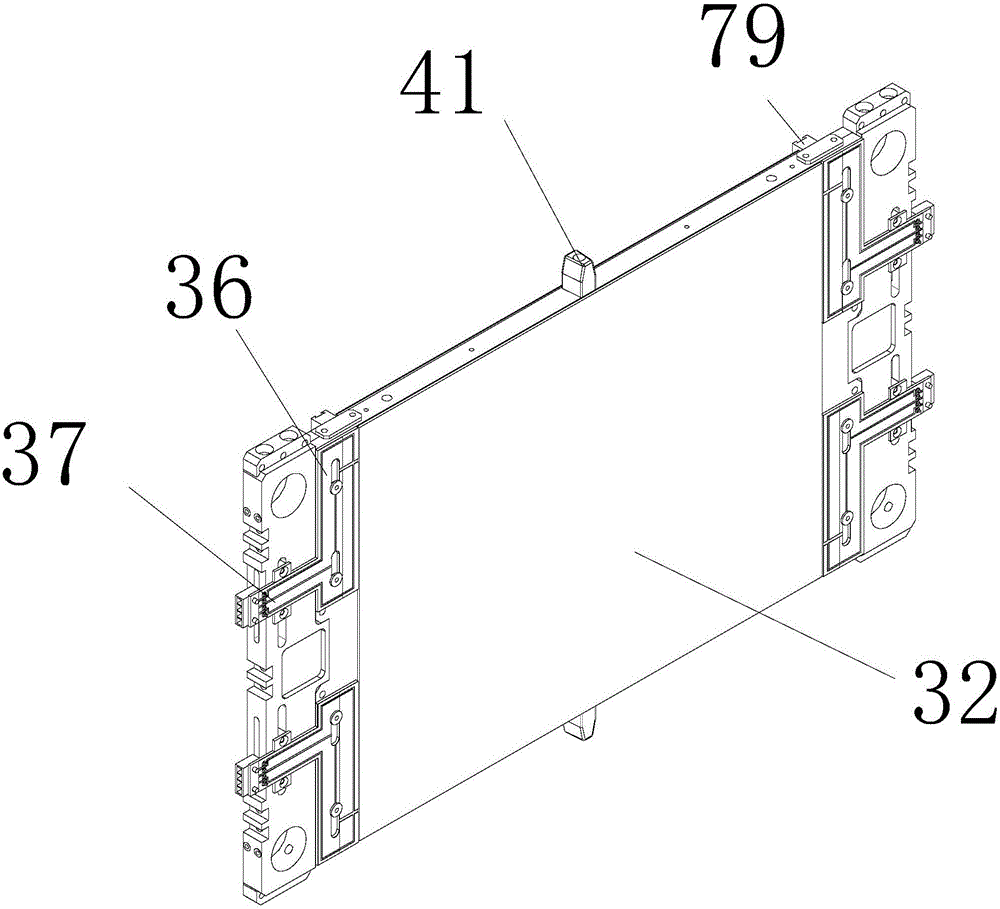

[0041]The clamps 3 are arranged in the outer frame, and each clamp 3 includes an adjustable supporting p...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 is that, as Figure 8 to Figure 12 As shown, a plurality of through holes 71 are also provided on the adjustable support plate 31. In this embodiment, four through holes 71 are set for one adjustable support plate 31. The through holes 71 are adjacent to the circuit board 36 and located in the circuit board. The middle position of the two poles of the plate 36, the clamp 3 also includes positioning wires 72, the two ends of the positioning wires 72 are fixed on the clamp 3 by adjustable bolts 73, and the positioning wires 72 pass through the adjustable supporting plates 31. Some through holes 71 are provided with an adjustment frame 74 at the fixed end of the upper end of the positioning wire 72, and an adjustment spring 75 connected with the positioning wire 72 is arranged in the adjustment frame 74 to realize adjusting the tightness of the positioning wire 72. The side edge of the adjustable supporting plate 31 i...

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is that, as Figure 13 and Figure 14 As shown, the circuit board 36 is provided with an anti-short circuit groove, and the anti-short circuit groove separates the terminal 37, and a silicone tube 78 is arranged in the anti-short circuit groove, and the silicone tube 78 is higher than the The contact surface of the terminal 37 is described above, so that after the blister tray 35 is installed, the silicone tube 78 will withstand the positive and negative ears of the lithium ion battery placed on the blister tray 35, which is impossible for the positive and negative ears of the lithium ion battery. It is in contact with the connection terminal 37 of the circuit board 36, which can avoid the short circuit problem caused by human error. Because the flexibility of the silicone tube 78 is good, when the cylinder 4 starts to apply pressure to the adjustable supporting plate 31, the adjustable supporting plate 31 The sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com