A cable laying device with corner function

A cable laying and functional technology, used in cable laying equipment, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of heavy cable weight, easy to wear cable insulation layer, limited cable trench space, etc. Small, increased footprint, small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

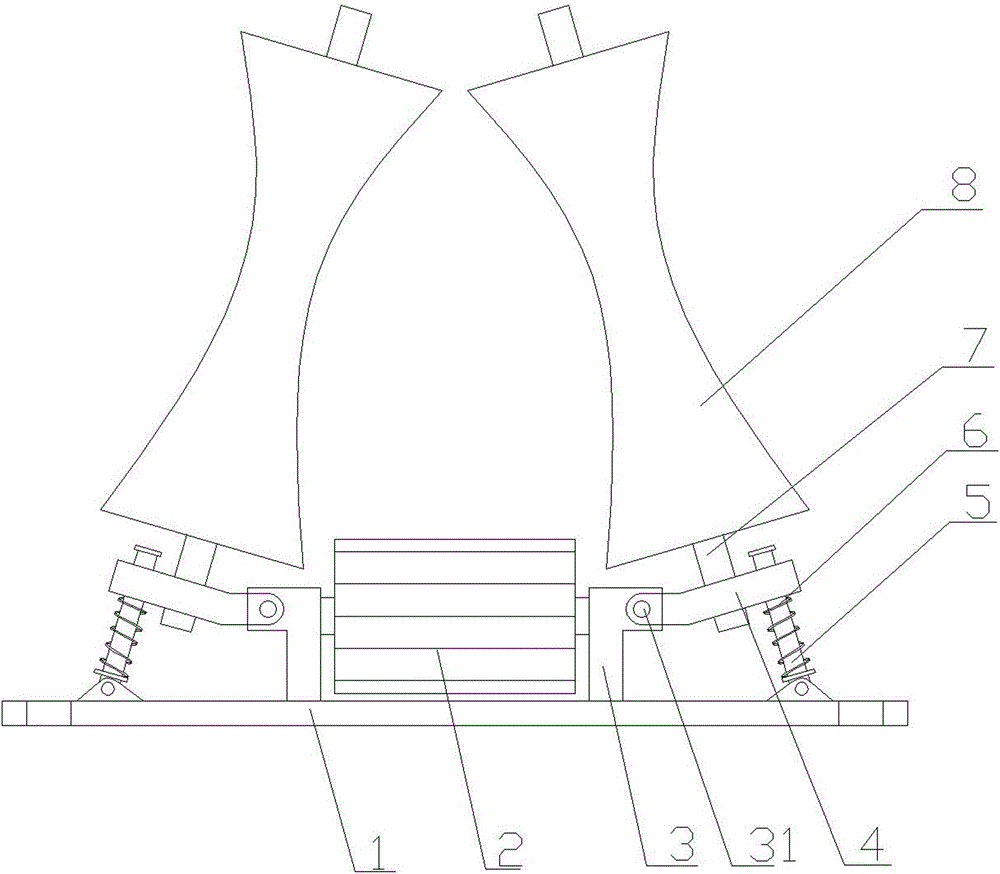

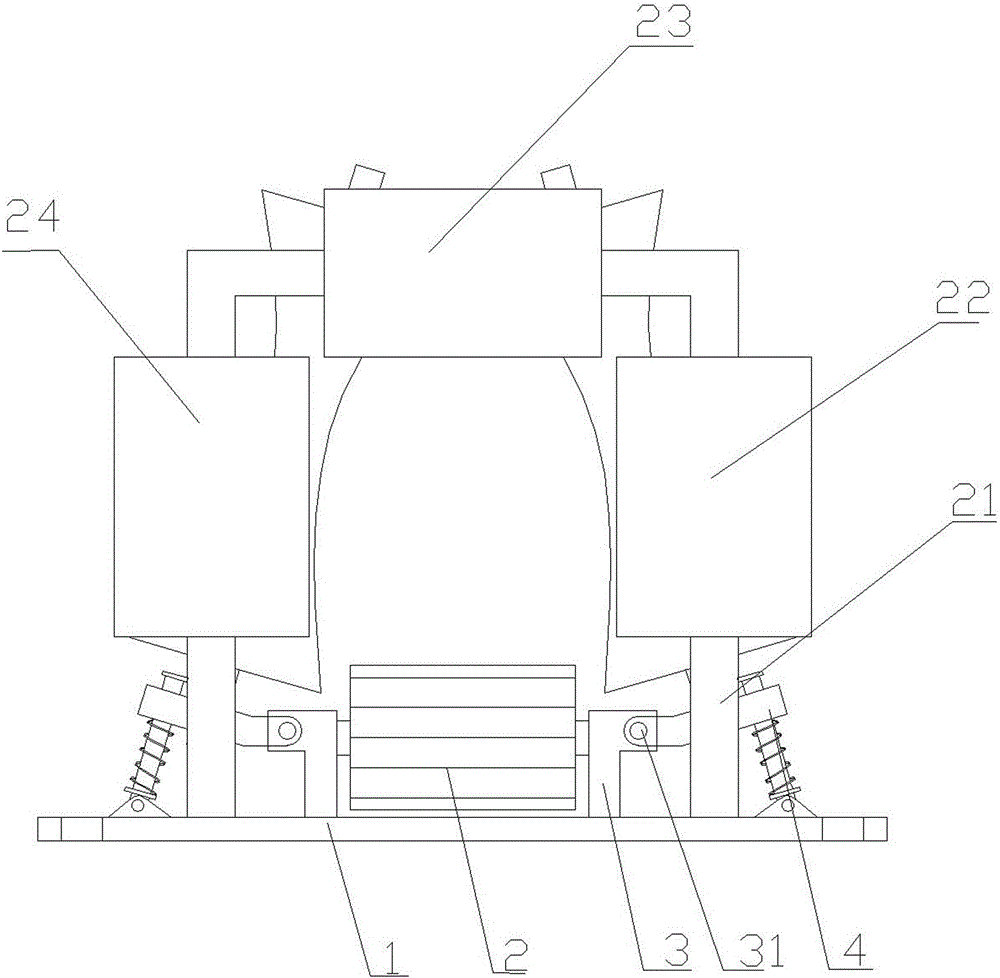

[0021] The following will be combined with Figure 1-5 The present invention will be described in further detail.

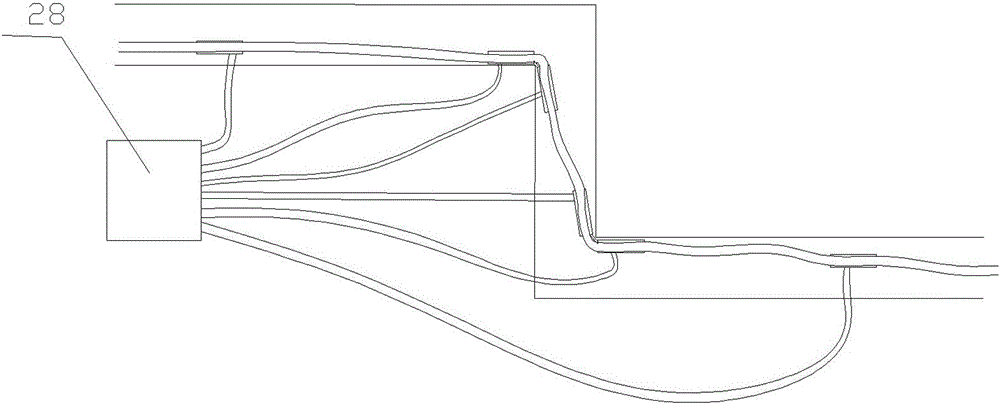

[0022] as attached Figure 1-4 As shown, a high-efficiency cable laying device with a corner function includes two laying bodies hinged by steel plates 25, and the two ends of the steel plate 25 are respectively connected to the two laying bodies through hinge shafts 26, and the steel plates 25 are provided with There is runner 27.

[0023] The laying body includes a base 1, a conveyor belt 2, a fixed frame 3, a pressure wheel 8 and a connecting rod 5 with a compression spring 6, the conveyor belt 2 is fixed on the base 1, and the fixed frame 3 is fixed on the On both sides of the conveyor belt 2, the connecting rod 5 is hinged on the base 1 and is located outside the fixed frame 3. The fixed frame 3 is hinged with a connecting plate 4 through a rotating shaft 31, and the other of the connecting plate 4 One end is sleeved on the outside of the connecting rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com