Method for stabilizing silanol group-containing polysiloxane solution, method for producing stabilized silanol group-containing polysiloxane solution, and stabilized silanol group-containing polysiloxane solution

一种聚硅氧烷溶液、硅烷醇基的技术,应用在分子量的稳定化领域,能够解决保存稳定性不充分等问题,达到保存稳定性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

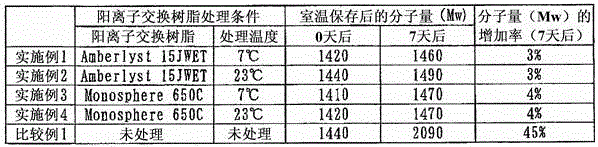

Embodiment 1~4 and comparative example 1)

[0046] Add 601.5g (2887mmol) of tetraethoxysilane (TEOS), 273.6g (1333mmol) of methyltriethoxysilane (MTEOS) and 44.1g (PhTMOS) into a 3000mL four-neck flask ( 222mmol) and 1324g of acetone, cooled to 10°C under blade stirring, added dropwise 292.2g of 0.01N hydrochloric acid over 20 minutes at 10-20°C, raised the temperature to 62°C, and stirred for 4 hours. To this solution, 1,766 g of PGMEA (propylene glycol monomethyl ether acetate) was added, while concentrating under reduced pressure at 40 to 60°C to replace PGMEA with acetone, hydrogen chloride, water, ethanol, and methanol to obtain 806.3 g PGMEA solution of silanol-containing polysiloxane. Moreover, hydrochloric acid which is a polycondensation catalyst can also be removed by this substitution. The PGME / PGMEA solution of the silanol group-containing polysiloxane was obtained by diluting the PGMEA solution of the silanol group-containing polysiloxane with 1021.3 g of PGME (propylene glycol monomethyl ether). In addit...

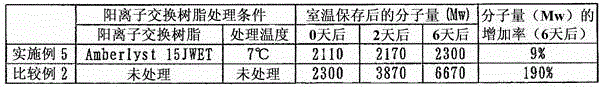

Embodiment 5 and comparative example 2)

[0054] Add 185.1g (888.4mmol) of tetraethoxysilane (TEOS) and 264.9g of acetone to a 1000mL four-neck flask, cool to 10°C under blade stirring, and drop 0.01N hydrochloric acid over 20 minutes at 10-20°C 58.43g, heated up to 62°C, and stirred for 4 hours. To this solution, 353.3 g of PGMEA was added, while concentrating under reduced pressure at 40 to 60° C., thereby replacing PGMEA with acetone, hydrogen chloride, water, and ethanol to obtain 159.4 g of silanol group-containing polysiloxane. PGMEA solution. Moreover, hydrochloric acid which is a polycondensation catalyst can also be removed by this substitution. The PGME / PGMEA solution of the silanol group-containing polysiloxane was obtained by diluting the PGMEA solution of the silanol group-containing polysiloxane with 197.3 g of PGME. In addition, the PGME / PGMEA solution of this silanol group-containing polysiloxane was used as the polymer solution of the comparative example 2.

[0055] Next, the PGME / PGMEA solution of...

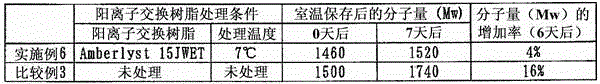

Embodiment 6 and comparative example 3)

[0061] Add 129.6g (621.9mmol) of tetraethoxysilane (TEOS), 39.6g (222.1mmol) of methyltriethoxysilane (MTEOS), and 8.64g of phenyltrimethoxysilane (PhTMOS) into a 1000mL four-necked flask (43.5mmol), N-(3-(triethoxysilyl)propyl) benzenesulfonamide 0.32g (0.89mmol) and acetone 267.2g, cooled to 10°C under blade stirring, at 10~20°C 59.23 g of 0.01N hydrochloric acid was added dropwise over 20 minutes, the temperature was raised to 62° C., and the mixture was stirred for 4 hours. 356.2 g of PGMEA was added to this solution, while concentrating under reduced pressure at 40 to 60° C., thereby replacing PGMEA with acetone, hydrogen chloride, water, and ethanol to obtain 160.4 g of silanol group-containing polysiloxane. PGMEA solution. Moreover, hydrochloric acid which is a polycondensation catalyst can also be removed by this substitution. The PGEE / PGMEA solution of the silanol group-containing polysiloxane was obtained by diluting the PGMEA solution of the silanol group-containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com