Horizontally mounted compressor

A compressor, horizontal type technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as difficult to increase the side pressure of electric components, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

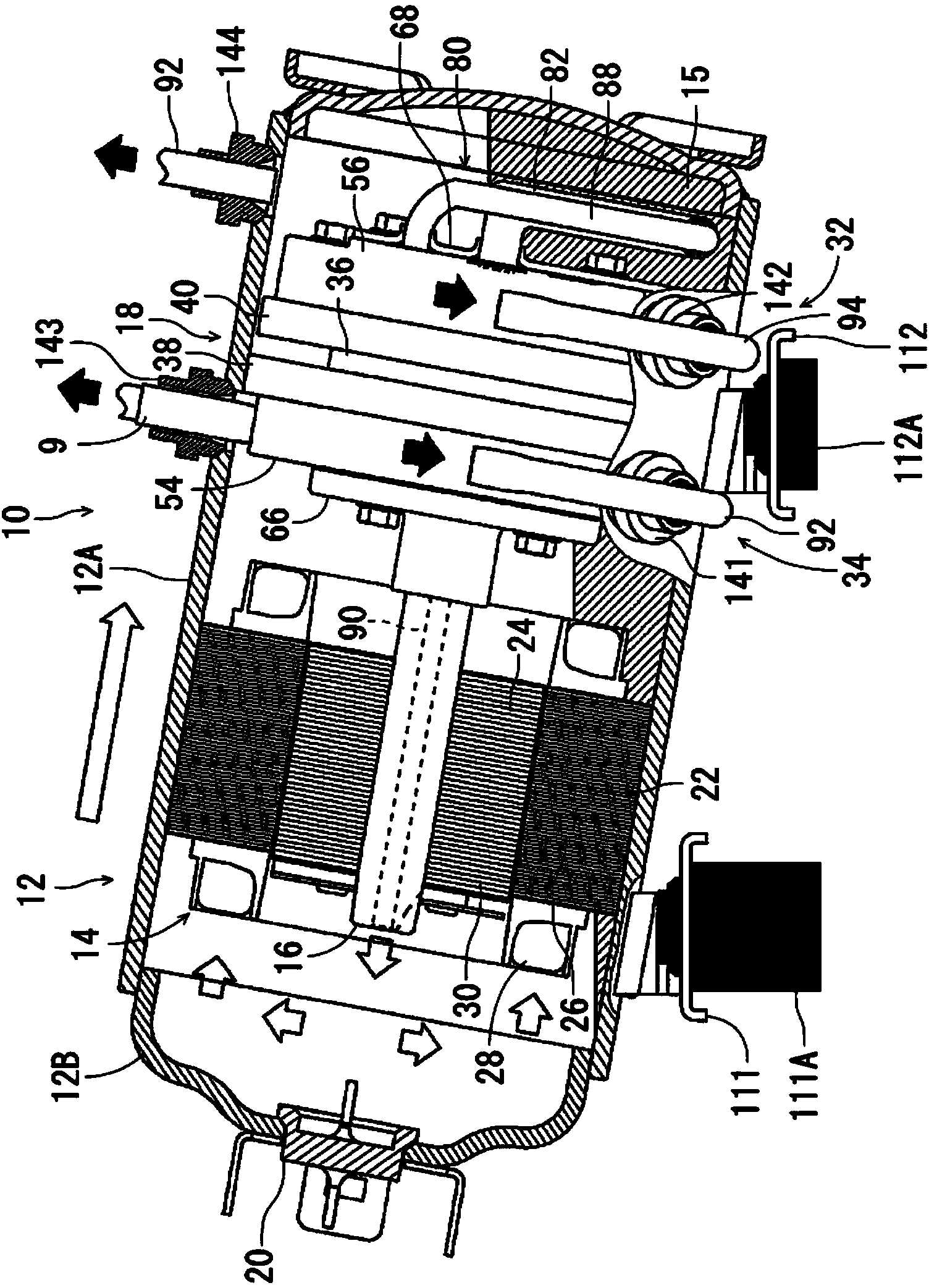

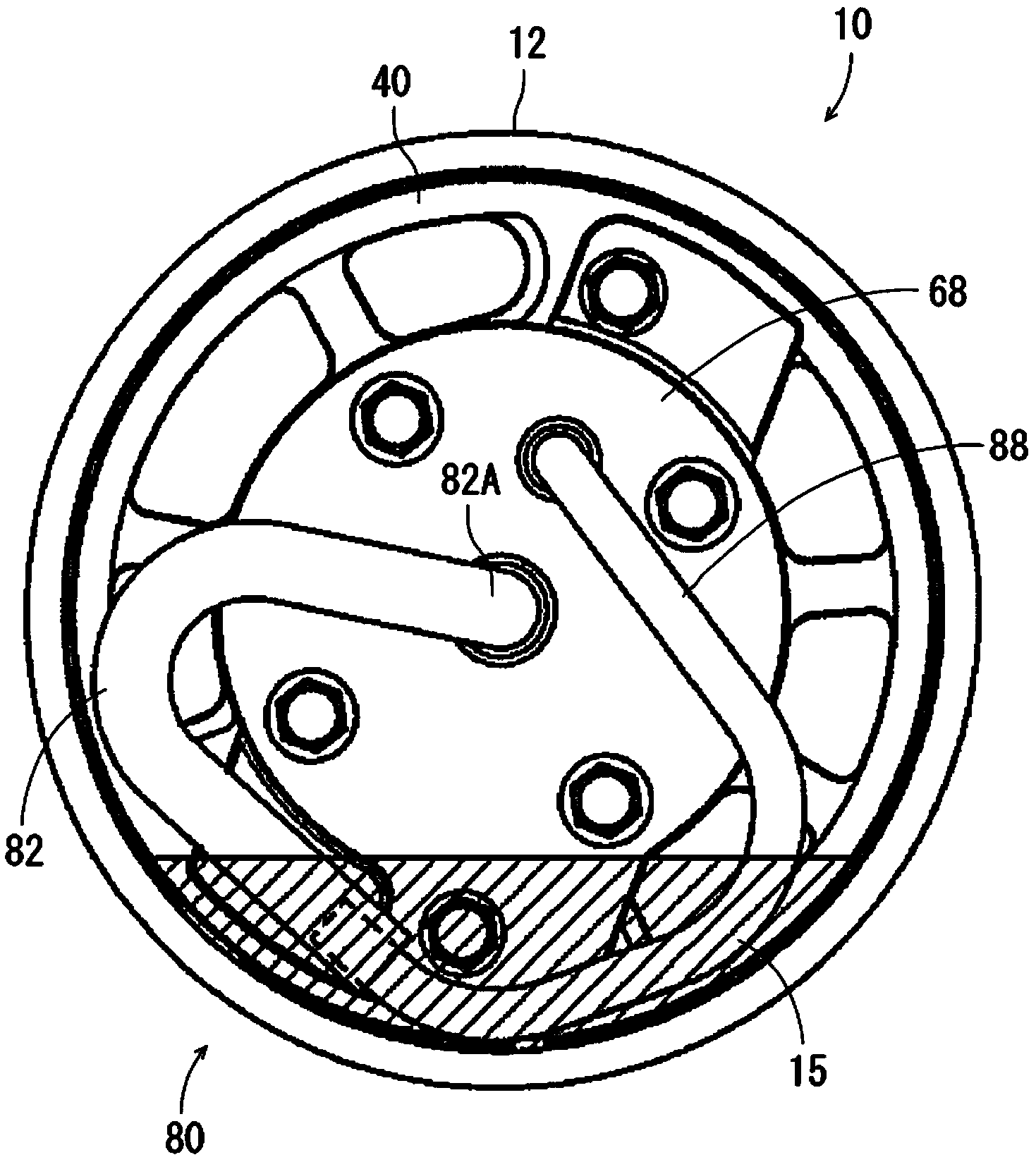

[0036] Hereinafter, embodiments of the present invention will be described in detail. In each figure, 10, as an embodiment of the horizontal type compressor of the present invention, is to convert carbon dioxide (CO 2 ) is used as a horizontal type internal intermediate pressure type multi-stage compression rotary compressor used as a refrigerant. This multi-stage compression rotary compressor (compressor) 10 has a horizontally elongated cylindrical airtight container 12 with both ends sealed, and the inner bottom of the airtight container 12 serves as an oil storage tank 15 . The airtight container 12 is composed of a container main body 12A and a substantially bowl-shaped end cap (lid body) 12B that closes the opening of the container main body 12A.

[0037] In this airtight container 12, an electric element 14 composed of an electric motor, a first compression element 32 and a second compression element driven by the rotation shaft 16 of the electric element 14 extending i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com