steamer

A technology of steaming and kettle bottom, applied in the field of dark tea processing equipment, can solve the problems of high energy consumption, difficult to grasp the degree of heating and humidification, low technical efficiency, etc., and achieve the effect of stable molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

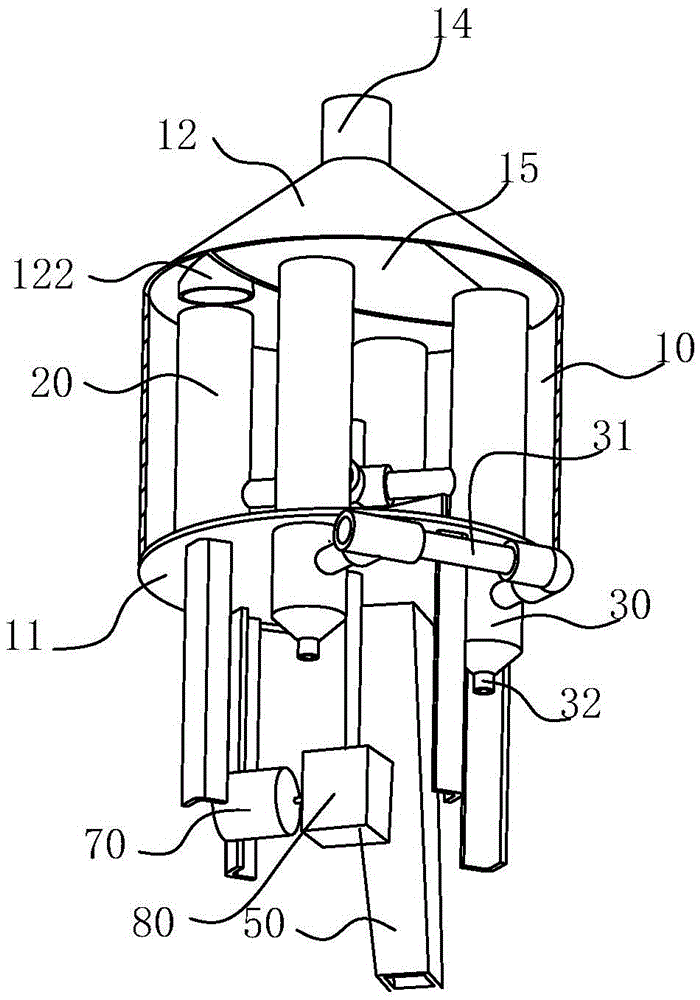

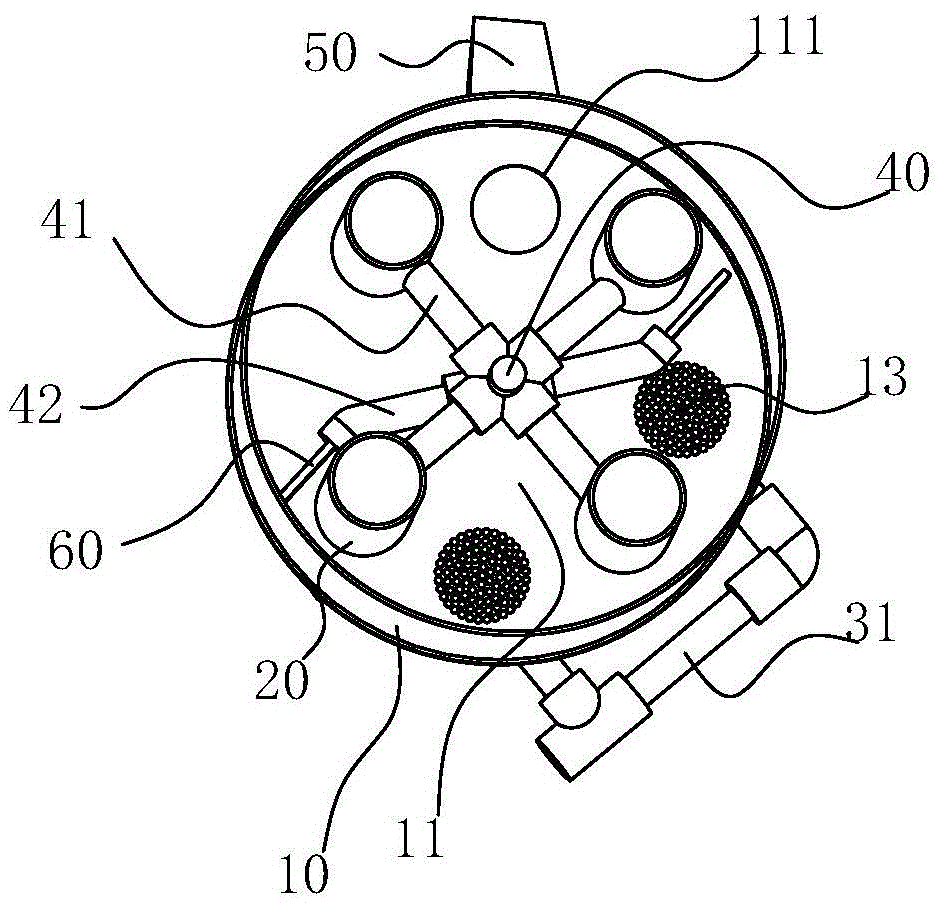

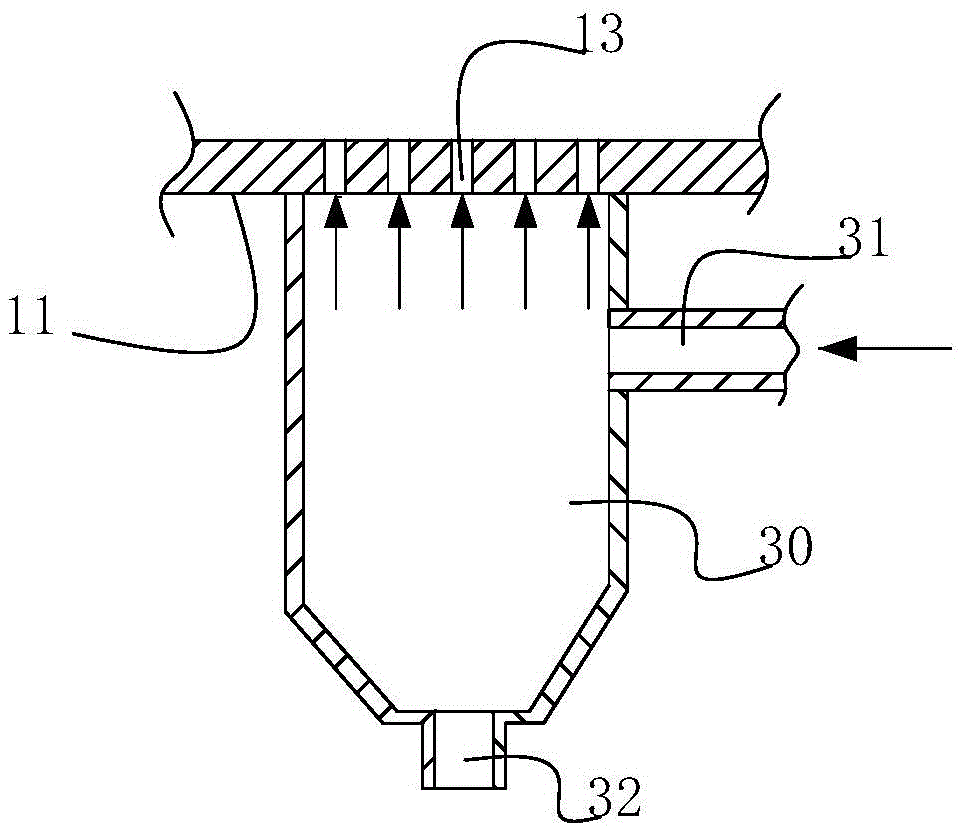

[0011] Such as figure 1 , figure 2 , Figure 4 As shown, a kind of steaming kettle comprises a tank-shaped kettle body 10, the bottom 11 of the kettle body 10 is located in a horizontal plane, and a feeding port 121 is provided on a kettle cover 12 located on the top, and a discharge port is provided on the bottom 11 of the kettle. 111, vent holes 13 are evenly and densely distributed on the bottom 11 of the tank next to the discharge port 111, and the area where the vent holes 13 are concentrated is consistent with the cross-sectional size and outline of the barrel 20 provided in the still cavity, and the vent holes 13 are communicated with the steam heat source. The material cylinder 20 is connected with the driving mechanism, and the driving mechanism drives the material cylinder 20 to sequentially index and move from the position aligned with the feeding port 121 , the vent hole 13 and the material discharging port 111 . In the drive mechanism, the motor 70 is decelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com