ti3+:tio2/tif3 composite semiconductor photocatalyst and preparation method thereof

A compound semiconductor and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that visible light cannot be effectively used, photocatalytic performance cannot be further improved, and further applications are hindered. Achieve good visible light absorption capacity, good visible light photocatalytic performance, and high commercial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Ti 3+ :TiO 2 / TiF 3 Preparation of composite semiconductor photocatalyst:

[0038] 2.5mmol titanium tetrachloride and 2.5mmol titanium tetrafluoride are completely dissolved in 45ml absolute ethanol, stirred for 5 minutes; then 1.875mmol elemental zinc (R ZT =3:8;R ZT , the molar ratio of the amount of Zn to Ti added), added to the above solution, and after fully stirring for 15 minutes, the solution was poured into a 120ml polytetrafluoroethylene reactor, and the reactor was put into an oven, and kept at 160°C for 32 Hours. After natural cooling, the obtained precipitate was repeatedly washed with absolute ethanol and deionized water three times, and then dried at 50°C.

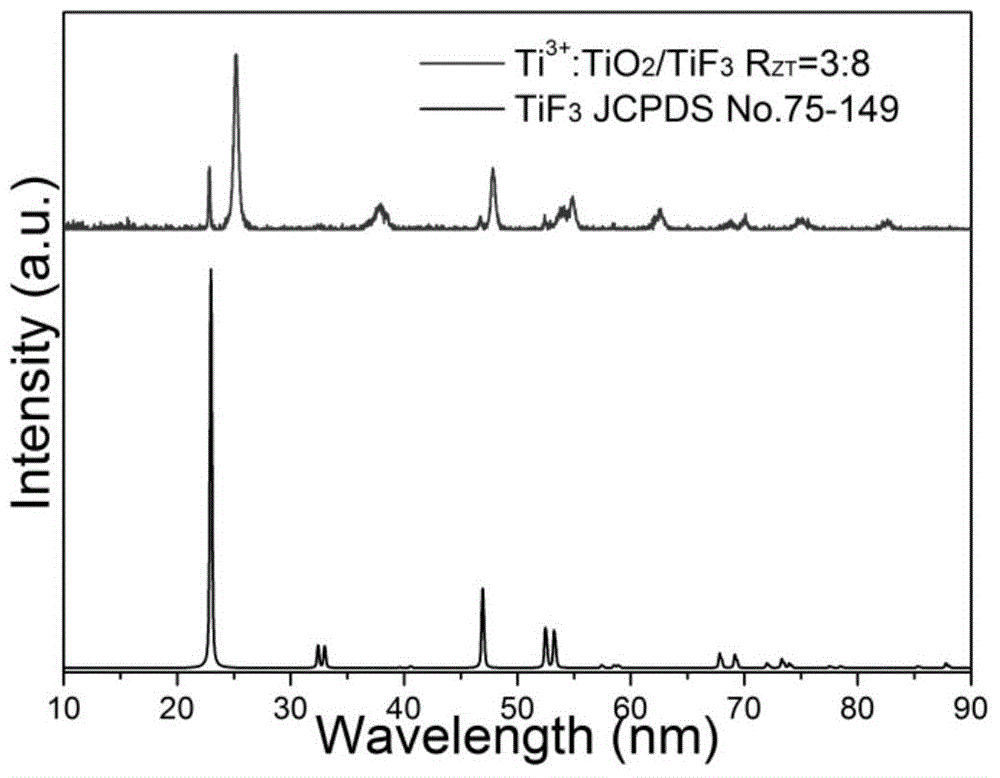

[0039] figure 1 It is the X-ray diffraction pattern of the product obtained in this embodiment, the top of the figure is the X-ray diffraction peak of the product obtained in the present embodiment, and the bottom part of the figure is the X-ray diffraction of the standard card (JCPDS No.75-...

Embodiment 2

[0043] (1) Ti 3+ :TiO 2 / TiF 3 Preparation of composite semiconductor photocatalyst:

[0044] 2.5 mmol of titanium tetrachloride and 2.5 mmol of titanium tetrafluoride were uniformly and completely dissolved in 45 ml of absolute ethanol, and stirred for 20 minutes. Then 2.5mmol elemental zinc (R ZT =4:8) was added to the above solution and stirred thoroughly for 10 minutes. Pour the solution into a 120ml polytetrafluoroethylene reactor, put the reactor into an oven, and keep the temperature at 180°C for 24 hours. After natural cooling, the obtained precipitate was repeatedly washed with absolute ethanol and deionized water three times, and then dried at 40°C.

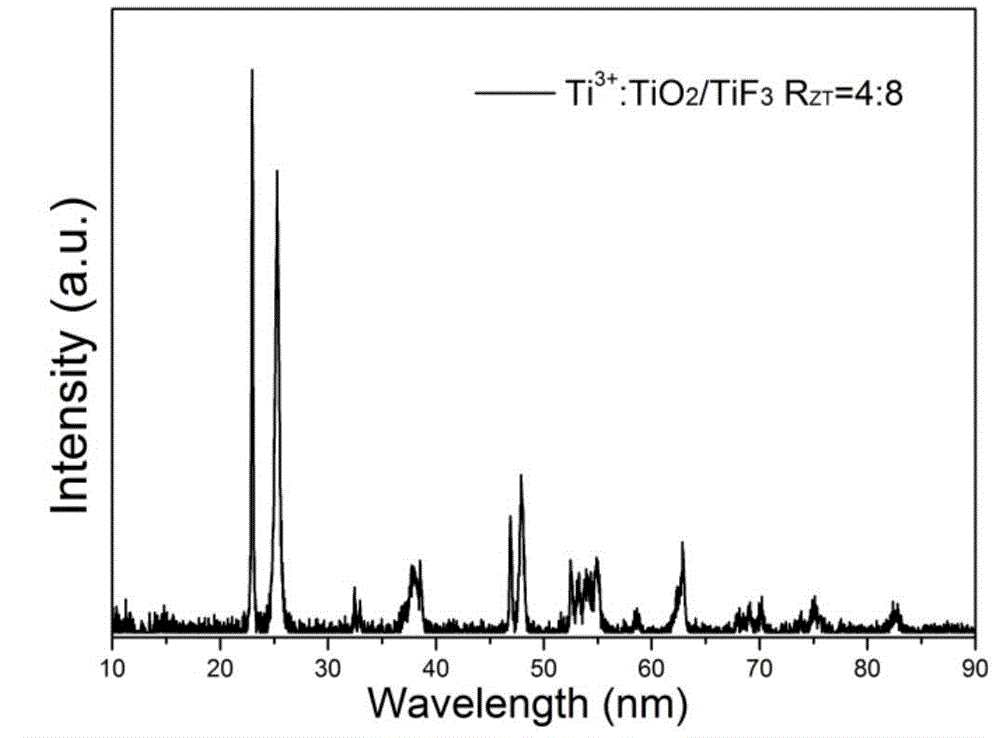

[0045] figure 2 It is the X-ray diffraction pattern of the product obtained in this embodiment, as can be seen from the figure, each diffraction peak of this product is the standard card (JCPDS No.21-1272) of anatase phase titanium dioxide and the standard card (JCPDS No. 75-149), there is no miscellaneous peak ...

Embodiment 3

[0049] (1) Ti 3+ :TiO 2 / TiF 3 Preparation of composite semiconductor photocatalyst:

[0050] 2.5 mmol of titanium tetrachloride and 2.5 mmol of titanium tetrafluoride were uniformly and completely dissolved in 45 ml of absolute ethanol and stirred for 15 minutes. Then 3.125mmol elemental zinc (R ZT =5:8) was added to the above solution and stirred thoroughly for 10 minutes. Pour the solution into a 120ml polytetrafluoroethylene reactor, put the reactor into an oven, and keep the temperature at 200°C for 18 hours. After natural cooling, the obtained precipitate was repeatedly washed with absolute ethanol and deionized water three times, and then dried at 60°C.

[0051] Figure 4 It is the X-ray diffraction pattern of the product obtained in this embodiment, as can be seen from the figure, each diffraction peak of this product contains the standard card (JCPDS No.21-1272) of anatase phase titanium dioxide and the standard card (JCPDS No. 75-149), and the diffraction peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com