Catalyst for preparing methanol through CO2 hydrogenation as well as preparation method and application of catalyst

A catalyst and hydrogen production technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve emissions and environmental pollution, catalysts are easy to sinter, methanol selectivity It can improve the reaction activity, good CO2 conversion and methanol yield, and high methanol selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

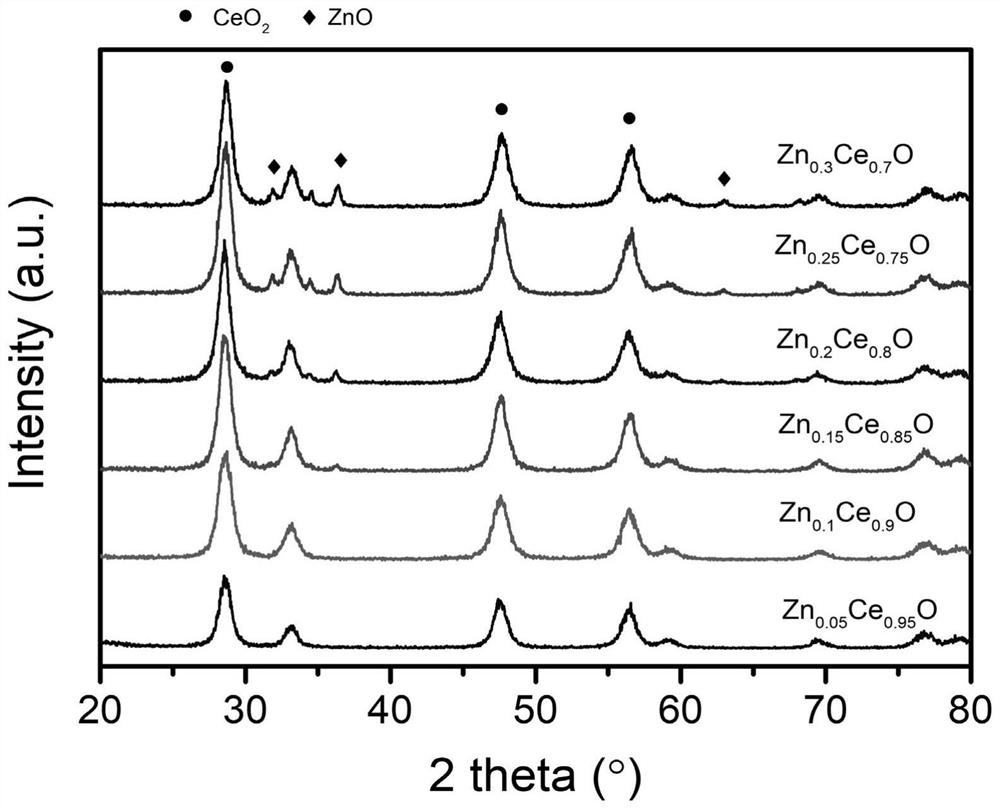

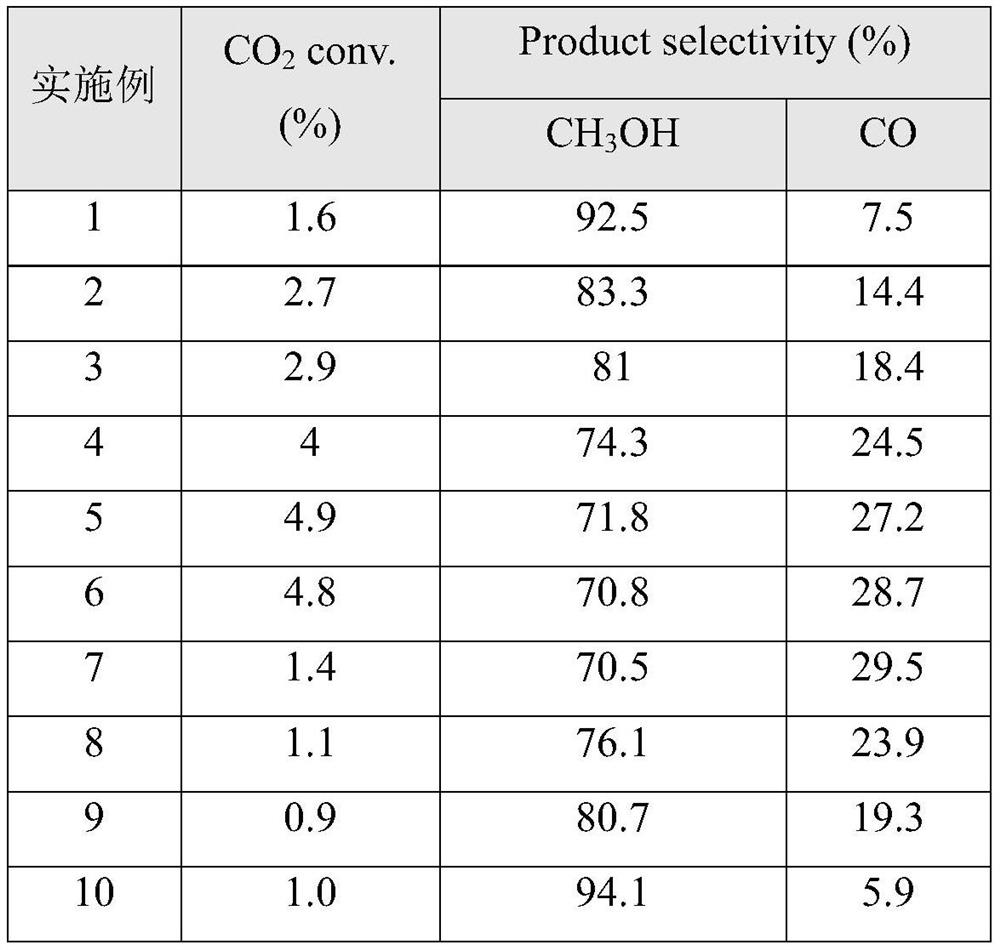

[0045] ZnCe oxide solid solution was prepared by co-precipitation method (Zn x Ce 1-x O). Dissolve zinc nitrate and cerous nitrate at a molar ratio of 0.05:0.95 in 240 mL of deionized water to form salt solution A (add two kinds of nitrates with a mass of 0.5 g and 14 g respectively), and stir at 30°C for 1 h. Then 6.660g of ammonium carbonate was dissolved in 220mL of deionized water and fully stirred and dissolved to form alkaline solution B. Transfer solution A to a round-bottomed flask and preheat it in an oil bath at 70°C, then add solution B to the round-bottomed flask at a rate of 3ml / min with a peristaltic pump under nitrogen purging, and then continue stirring at 70°C 3h. The resulting precipitate was cooled to room temperature, and the precipitate and the solution were separated under high-speed centrifugation. The precipitate was washed with deionized water and then centrifuged again. After repeating three times, the precipitate was dried at 60°C for 12h, and the...

Embodiment 2

[0048] ZnCe oxide solid solution was prepared by co-precipitation method (Zn x Ce 1-x O). Dissolve zinc nitrate and cerous nitrate at a molar ratio of 0.1:0.9 in 240 mL of deionized water to form salt solution A (the mass of the two nitrates added is 1 g and 13.3 g respectively), and stir at 30°C for 1 h. Then 6.660g of ammonium carbonate was dissolved in 220mL of deionized water and fully stirred and dissolved to form alkaline solution B. Transfer solution A to a round-bottomed flask and preheat it in an oil bath at 70°C, then add solution B to the round-bottomed flask at a rate of 3ml / min with a peristaltic pump under nitrogen purging, and then continue stirring at 70°C 3h. The resulting precipitate was cooled to room temperature, and the precipitate and the solution were separated under high-speed centrifugation. The precipitate was washed with deionized water and then centrifuged again. After repeating three times, the precipitate was dried at 60°C for 12h, and then bak...

Embodiment 3

[0051] ZnCe oxide solid solution was prepared by co-precipitation method (Zn x Ce 1-x O). Dissolve zinc nitrate and cerous nitrate at a molar ratio of 0.15:0.85 in 240 mL of deionized water to form salt solution A (add two nitrates with a mass of 1.5 g and 12.5 g respectively), and stir at 30°C for 1 h. Then 6.660g of ammonium carbonate was dissolved in 220mL of deionized water and fully stirred and dissolved to form alkaline solution B. Transfer solution A to a round-bottomed flask and preheat it in an oil bath at 70°C, then add solution B to the round-bottomed flask at a rate of 3ml / min with a peristaltic pump under nitrogen purging, and then continue stirring at 70°C 3h. The resulting precipitate was cooled to room temperature, and the precipitate and the solution were separated under high-speed centrifugation. The precipitate was washed with deionized water and then centrifuged again. After repeating three times, the precipitate was dried at 60°C for 12h, and then baked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com