A kind of functional furan resin and preparation method thereof

A furan resin and functional technology, applied in the fields of bioengineering, environmental engineering, and chemical engineering, can solve the problems of inability to meet the requirements of microbial treatment of industrial wastewater, difficult and low-cost large-scale preparation, complex preparation process, etc., and achieve a simple preparation method. Easy to implement, easy to popularize and apply, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 1, the invention provides a kind of preparation method of functional furan resin, comprises the steps:

[0026] S1: Mix liquid furan resin and solid anthraquinone in a certain proportion and stir to form a uniform liquid;

[0027] S2: standing the homogeneous liquid obtained in step S1 at 10-90° C. for 0.1-24 hours to form a solid;

[0028] S3: keeping the solid obtained in step S2 at 100-150° C. for 0.5-10 hours to obtain a functional furan resin.

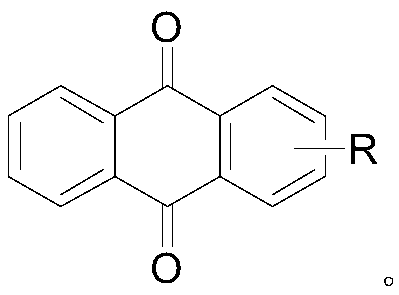

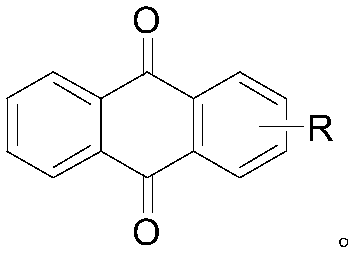

[0029] Wherein, in the step S1, anthraquinone has the following general chemical structure formula:

[0030]

[0031] Wherein, in the general chemical structure formula of anthraquinone, the substituent R includes but not limited to: hydrogen, sulfonic acid group, nitro group, halogen, alkyl group, alkoxyl group and hydroxyl group, and can be selected from one of the above substituent groups species, or a mixture of any two or more of the above substituents.

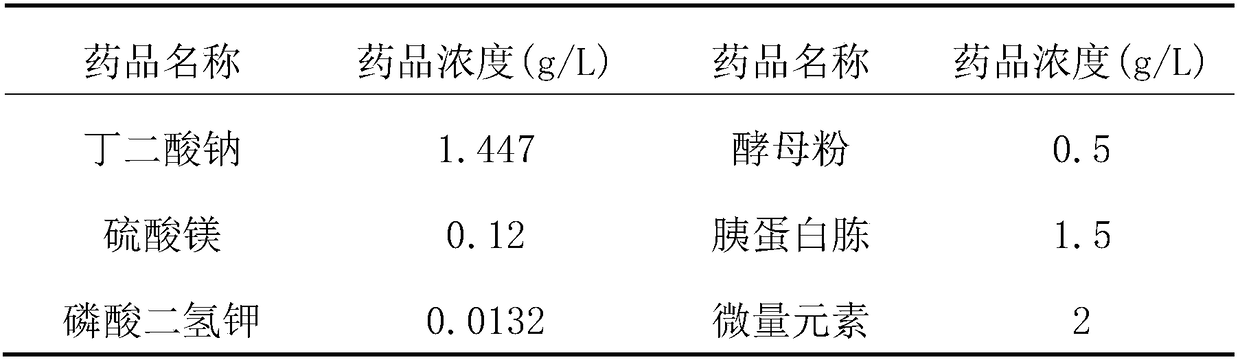

[0032] Wherein, in the step S1, it also includes uniformly...

Embodiment 1

[0059] S1: Mix 100g of liquid furan resin and 1g of anthraquinone and stir evenly to obtain a viscous liquid;

[0060] S2: standing the viscous liquid obtained in step S1 at 90° C. for 0.1 h to form a solid;

[0061] S3: Keep the solid obtained in step S2 at 100°C for 10 hours to obtain 81 g of functional furan resin, which contains anthraquinone 5.9×10 -5 mol\g.

[0062] Table 4: Catalytic properties of functional furan resins

[0063]

Embodiment 2

[0065] S1: Mix 100g of liquid furan resin and 20g of anthraquinone and stir evenly to obtain a viscous liquid;

[0066] S2: Put the viscous liquid obtained in step S1 at 70°C for 12 hours to form a solid;

[0067] S3: Keep the solid obtained in step S2 at 120° C. for 7 hours to obtain 97 g of functional furan resin, which contains anthraquinone 9.9×10 -4 mol\g.

[0068] Table 5: Catalytic properties of functional furan resins

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com