Method for preparing 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate by condensation of isobutyraldehyde

A technology of pentanediol monoisobutyrate and isobutyraldehyde, which is applied in the preparation of aldehyde redox, separation/purification of carboxylate, organic chemistry, etc., can solve the problem of high quality requirements of raw material isobutyraldehyde and complex reaction process , the catalyst is toxic and other problems, to achieve the effect of environmental friendliness, high yield and less impurities in the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

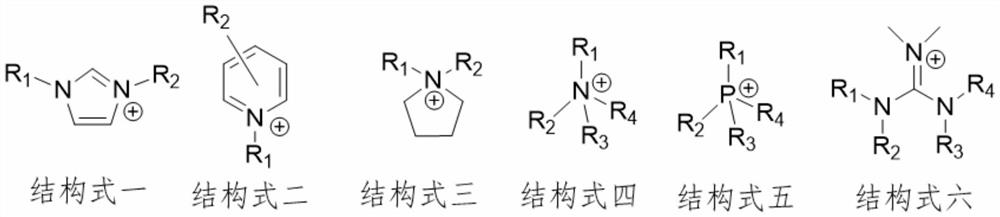

Embodiment 1

[0031] In this embodiment, a 100mL reaction kettle was used and heated in an oil bath. Add 50g of isobutyraldehyde to the reaction kettle, then add 0.5g of 1-methyl-3-butyl-imidazolium tetrafluoroborate, seal the reaction kettle, heat to 100°C, react for 20h, cool down after the reaction is completed , the measured yield of alcohol ester-12 was 71.8%, and the total impurity content was 1.56%.

Embodiment 2

[0033] Use a 1000L reactor and use steam heating. Add 500Kg isobutyraldehyde in the reactor, add 10Kg tetrabutylammonium hydroxide again, seal the reactor, heat to 80 ℃, react for 24h, after the reaction is completed, the reaction material is cooled down, and the yield of alcohol ester-12 is measured as 75.6%, and the total impurity content is 1.28%.

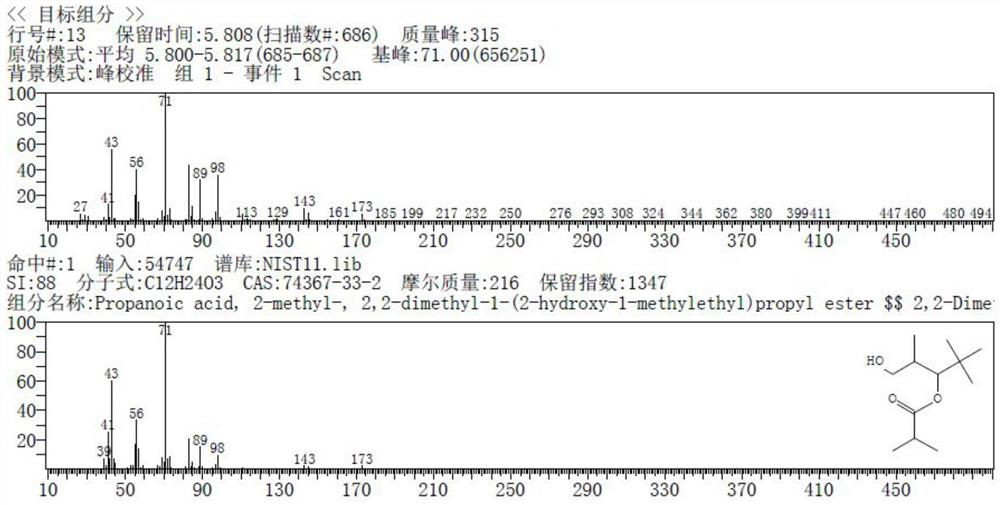

[0034] The reaction materials are sent to three rectification towers in series for rectification, and alcohol ester-12 is extracted from the top of the third rectification tower. The mass spectrometry test results are shown in figure 1 As shown in Figure A, with figure 1 Figure B is completely consistent with a purity of 99.5%. The ionic liquid catalyst remaining in the tower kettle is recovered.

Embodiment 3

[0036] In this embodiment, a 100mL reaction kettle was used and heated in an oil bath. Add 50g isobutyraldehyde in reactor, and add the ionic liquid catalyst (tetrabutylammonium hydroxide) that 0.25g embodiment 2 reclaims, be heated to 200 ℃, react 20h, measure the yield of alcohol ester-12 after completion of reaction is 73.6%, and the total impurity content is 1.18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com