Cord fabric dipping control system

A control system and cord fabric technology, applied in the chemical fiber field, can solve the problems affecting the dipping quality of the cord fabric, affecting the surface cleanliness of the dipping roller, etc., and achieve the effect of reducing the height and eliminating the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

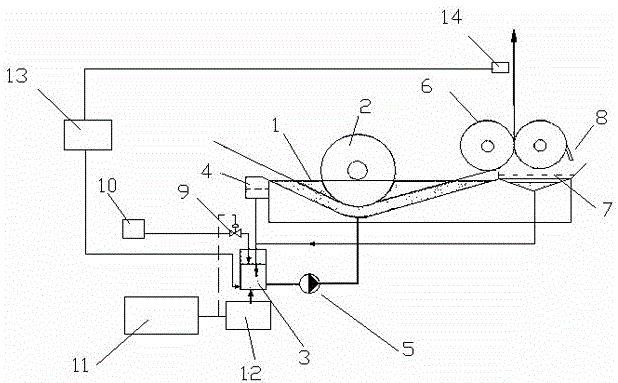

[0032] see figure 1 , the present invention relates to a cord fabric dipping control system, comprising a dipping tank 1, a dipping roller 2 and a circulation tank 3, the dipping roller 2 is arranged above the dipping tank 1 through a bearing, and is connected with the dipping tank 1 The glue inside is not in contact, so it can be free from pollution during the production process and avoid maintenance work; when working, the lower part of the dipping roller 2 is immersed in the glue in the dipping tank 1, and the cord fabric first enters the glue, and then with The dipping roller 2 contacts, then separates from the dipping roller 3, and finally leaves the glue solution. During the whole process, the entry point and separation point of the cord fabric and the dipping roller are completely under the dipping liquid surface, eliminating the foam generated by contact with air.

[0033] An overflow tank 4 is provided on the side where the cord fabric is introduced into the dipping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com