Drilling device for wheel insert

A drilling device and insert technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as drilling, and achieve high processing efficiency, advanced technology and high positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

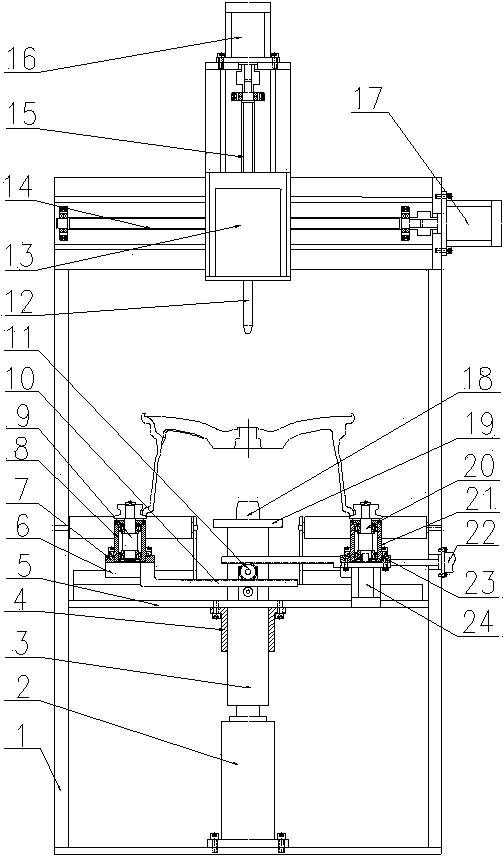

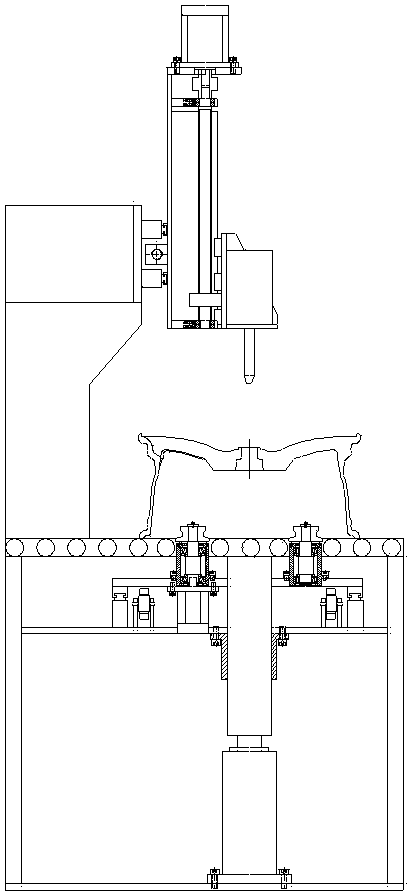

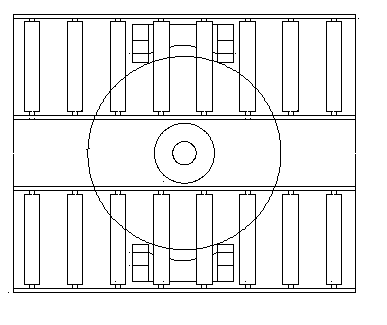

[0014] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

[0015] The device consists of frame 1, lifting cylinder 2, lifting column 3, guide sleeve 4, base plate 5, guide rail 6, left slide plate 7, left bearing seat 8, left shaft 9, rack 10, gear 11, drill bit 12, power head 13. Horizontal sliding table 14, vertical sliding table 15, servo motor Ⅰ16, servo motor Ⅱ17, mandrel 18, tray 19, right shaft 20, right bearing seat 21, clamping cylinder 22, right sliding plate 23 and servo motor Ⅲ24 The lifting cylinder 2 is fixed on the bottom of the frame 1, the output end of the lifting cylinder 2 is connected to the bottom of the lifting column 3; the tray 19 is fixed on the upper end of the lifting column 3, and the mandrel 18 matched with the center hole of the wheel is fixed on the top of the tray 19 The guide sleeve 4 matched with the lifting column 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com