A high-efficiency wire cutting machine guide wheel base and its guide wheel set

A wire cutting machine and guide wheel base technology, which is applied to electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of difficult work, affecting the working efficiency of the wire cutting machine, wasting time and energy, and saving time. and energy, low manufacturing cost and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

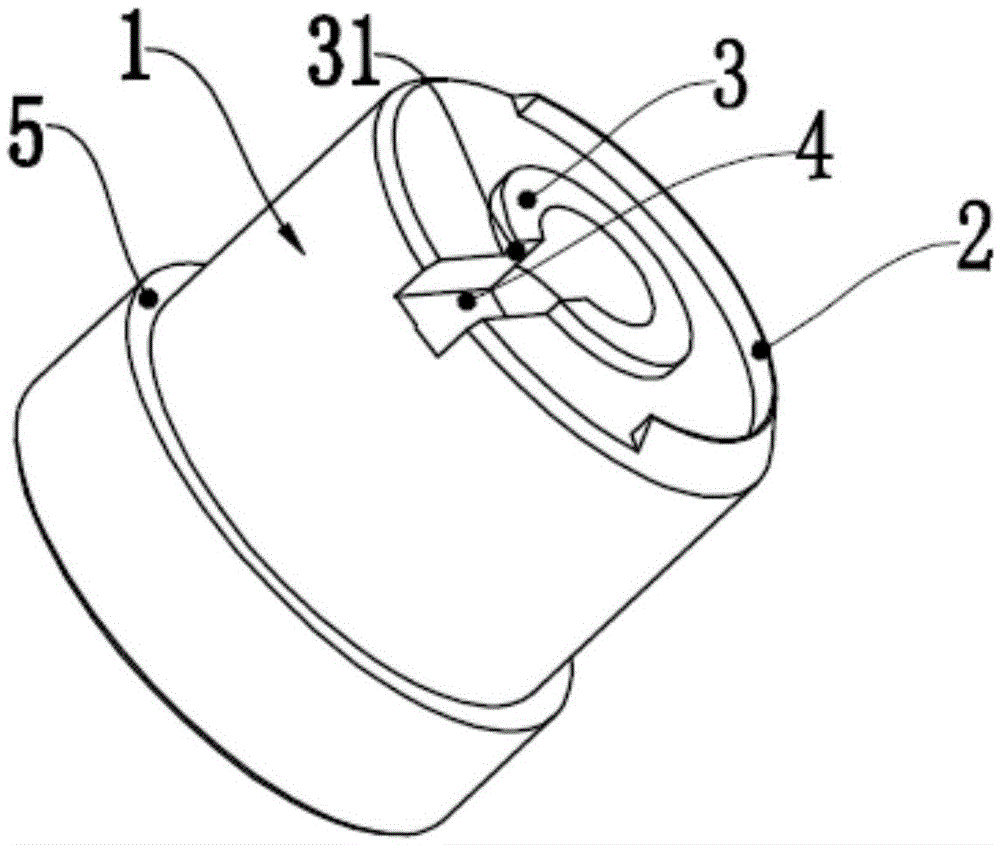

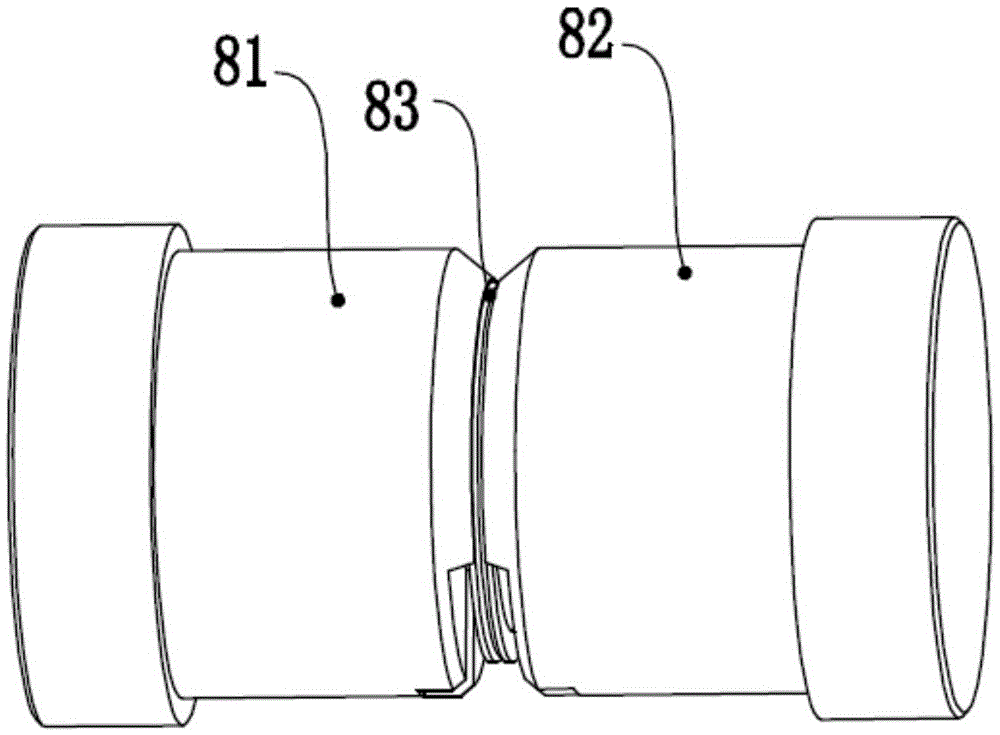

[0023] A high-efficiency wire cutting machine guide wheel seat, the middle part of the guide wheel seat 1 is provided with a bearing through hole, the edge of the guide wheel seat 1 is provided with an outer convex ring 2, and the outer convex ring 2 is inclined inward and gradually becomes smaller ; The edge of the bearing through hole in the middle of the guide wheel seat is provided with a convex ring 3 .

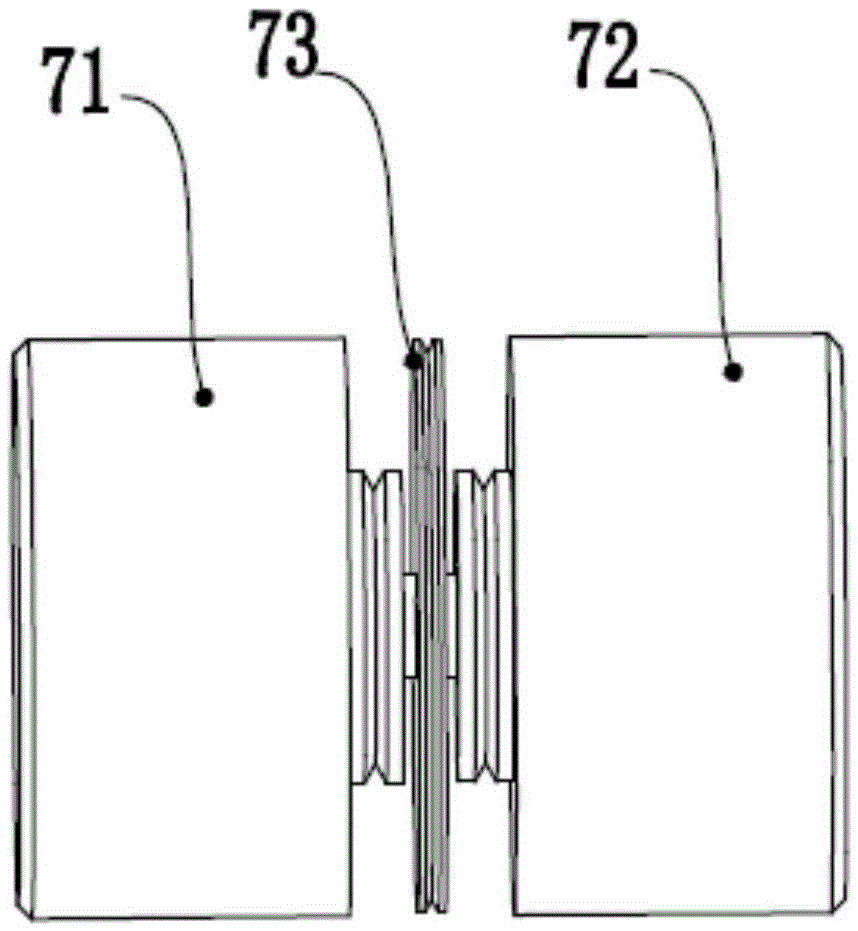

[0024] In wire cutting technology, the electrode wire runs between multiple guide wheel sets. The guide wheel group is made up of described guide wheel seat 1 and guide wheel 83. The outer convex ring 2 on the guide wheel seat 1 is matched with the edge of the wire groove on the guide wheel 83, so that the wire electrode does not need to be aligned with the wire groove on the guide wheel 83 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com