Supporting structure for plastic part hot melting welding column

A support structure and heat fusion welding technology, applied in the field of support structures, can solve the problems of low support structure support strength, high friction noise between parts, poor coordination stability, etc., achieve good assembly adaptability, eliminate friction noise, and improve compression resistance The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

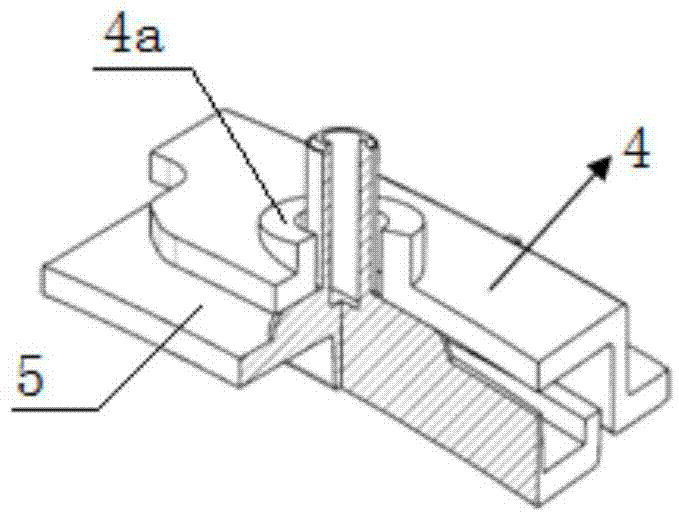

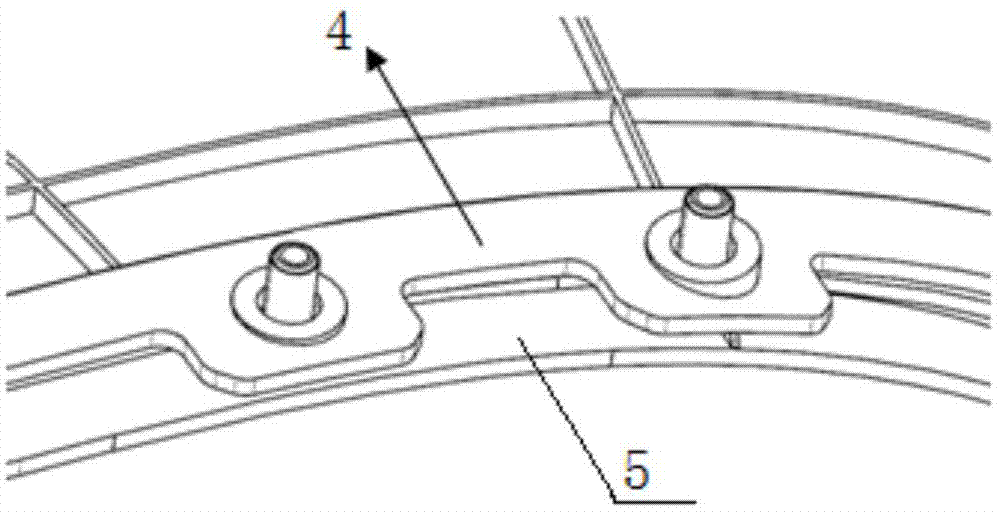

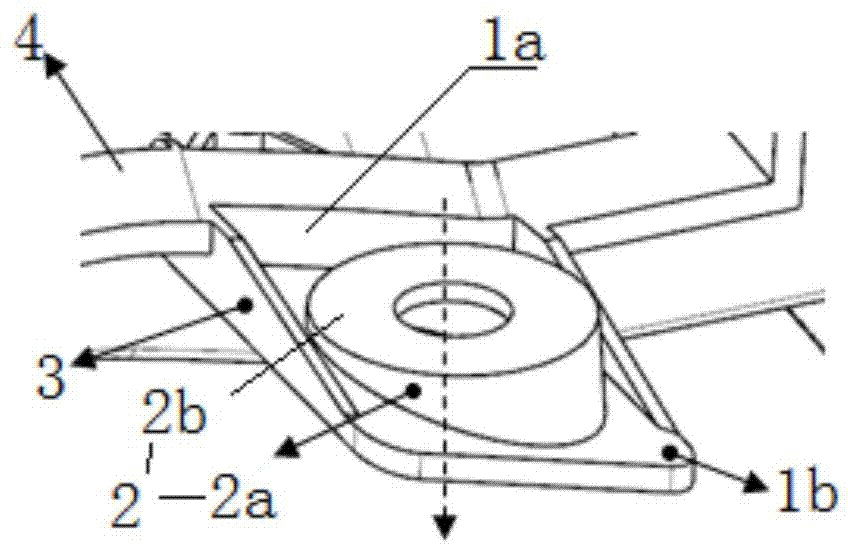

[0030] to combine Figure 3 to Figure 8 As shown, a supporting structure of a hot-melt welding column of plastic parts is fixedly connected with the flange 4 of the matching part. The supporting structure is composed of a supporting platform 1, a column platform 2 fixed on the supporting platform and a reinforcing rib 3.

[0031] The support platform is composed of two parts, the straight extension section 1a and the extension section 1b, which are connected together. Image 6 , the straight section controls the distance between the support platform and the substrate, and the stretching direction of the straight section is the same as the demoulding direction,

[0032] The straight extension section is fixedly connected to the lower edge of the front end of the flange of the fitting and extends downward, and the extension section is fixedly connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com