Ship follow-up steering system

A rudder system and follow-up technology, applied in the field of steering systems, can solve the problems of unintuitive operators, low steering precision, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

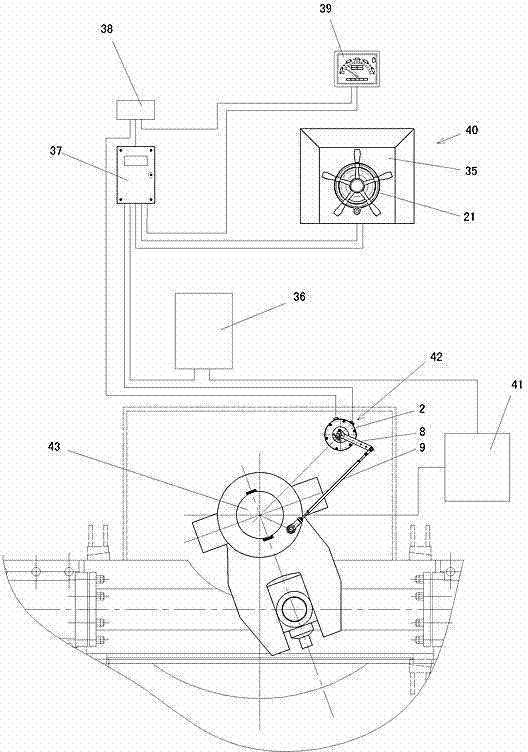

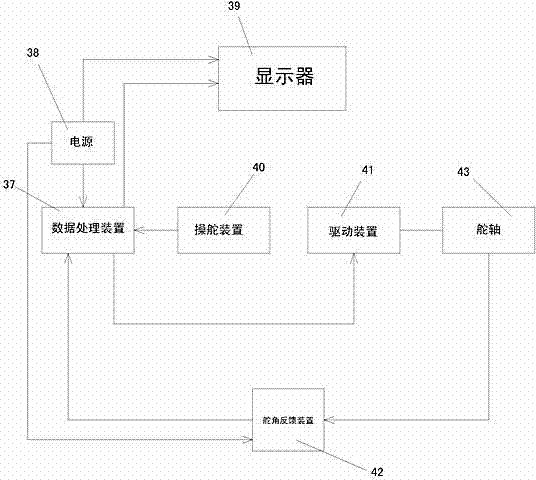

[0019] Such as figure 1 , 2 Shown: 40 is steering mechanism, and 41 is the driving device 41 that drives rudder shaft 43 to rotate, and 38 is power supply. Steering mechanism 40 is connected with data processing device 37, display 39 successively, and data processing device 37 connects driving device 41, and driving device connects rudder shaft 43, and rudder shaft 43 connects rudder angle feedback device 42, and rudder angle feedback device connects data processing device 37, The power supply 38 is connected to the display 39 , the data processing device 37 and the rudder angle feedback device 42 .

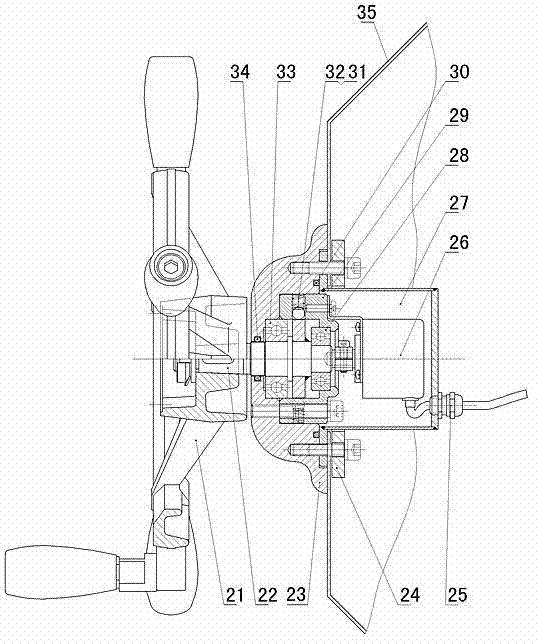

[0020] Such as image 3 , 4 As shown: the steering mechanism 40 includes a steering hand wheel 21, and the center hole of the steering hand wheel 21 is equipped with a wheel shaft 22 through a key connection. A second sealing ring 34 is disposed between the axle 22 and the housing 23 .

[0021] The axle 22 is supported in the housing 23 through bearings, and the housing 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com