Poultry egg conveying automatic positioning and packaging robot and working method thereof

An automatic positioning and automatic packaging technology, applied in the field of egg collection and packaging, can solve the problems of high cost of the whole machine, increase the cost of the control system, and affect the promotion and application, so as to reduce labor costs and production costs, improve labor productivity, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail with reference to the drawings.

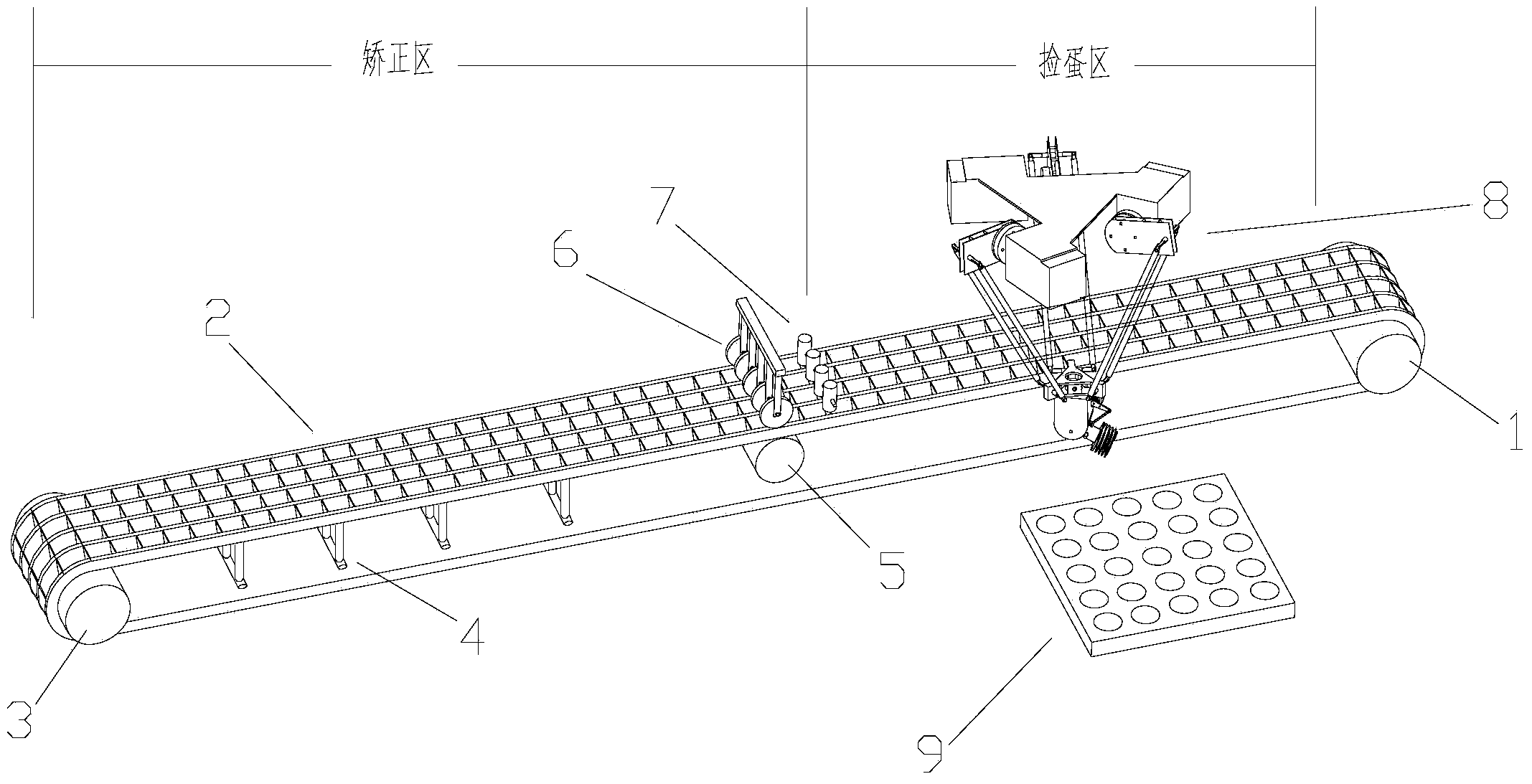

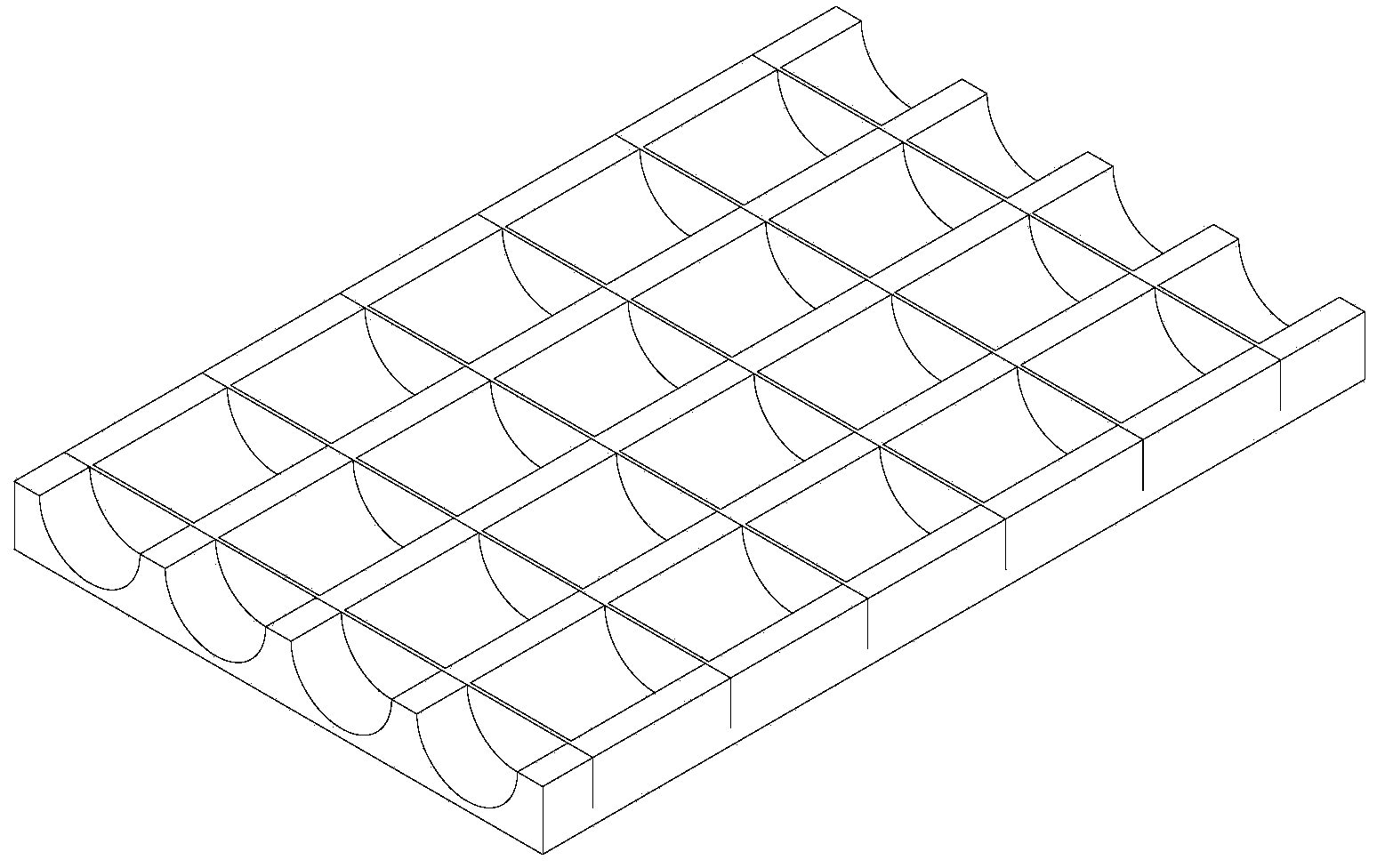

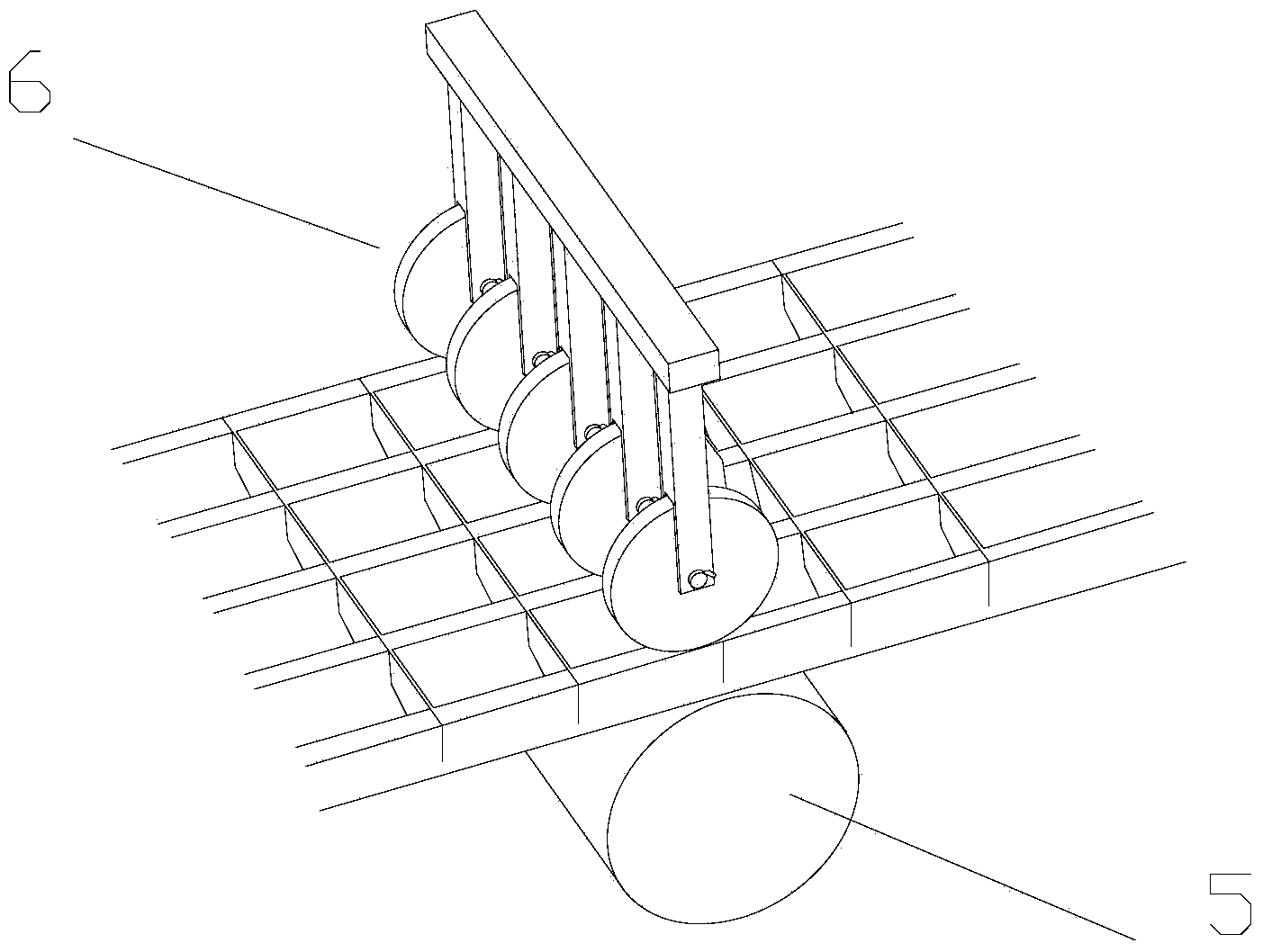

[0035] The egg transport device is such as figure 1 As shown, it is composed of an egg-collecting trough conveyor belt 2, a driving roller with a photoelectric encoder 1, a driven roller 3, a servo motor and a conveyor belt pressing device. The egg collection trough conveyor belt such as figure 2 As shown, the surface is made of silicone material, which is divided into a plurality of rectangular silicone grooves in the width and length directions of the surface of the conveyor belt. Each rectangular silicone groove forms a hollow egg collecting groove with an arc-shaped bottom and an arc-shaped structure in the width direction The groove ridge is divided into multiple rows in the length direction by the linear structure groove ridge. The groove depth of each grid is half of the egg width, the groove width is slightly larger than the width of the egg, and the groove length is slightly larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com