Construction method of building pile body in underground space and building structure of underground space

A technology of underground space and construction method, which can be applied to underwater structures, buildings, infrastructure projects, etc., and can solve the problems of increasing construction costs, long construction period, and low effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

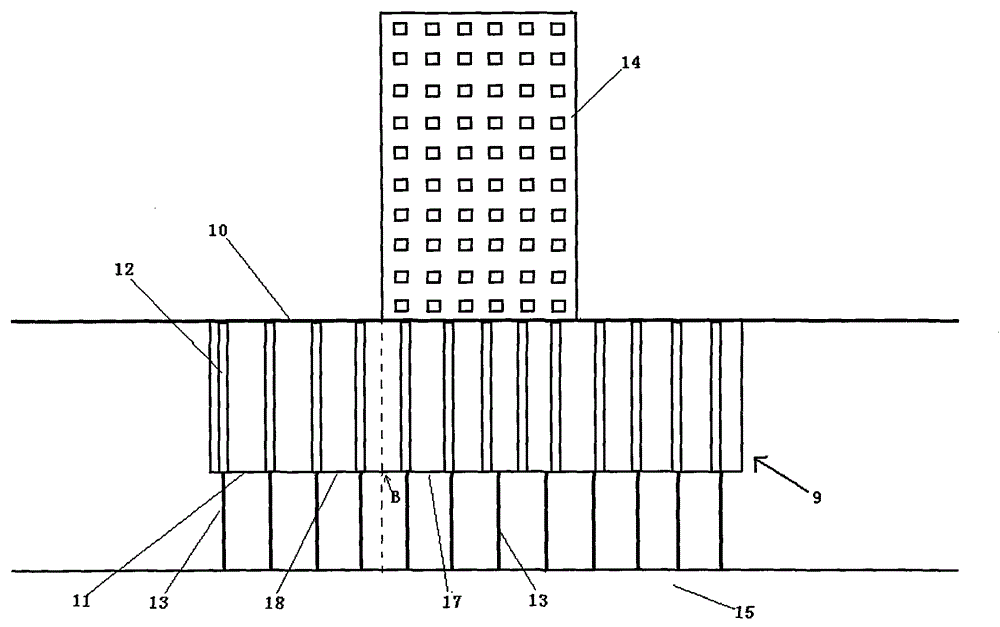

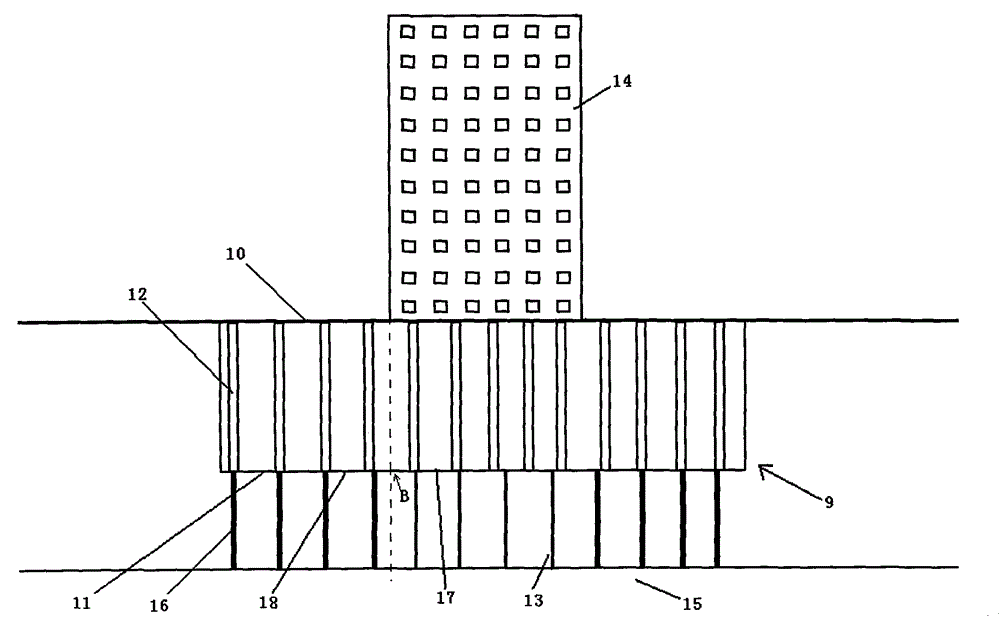

[0033] The building pile body construction method of the underground space of the present invention, wherein, such as figure 2 As shown, the underground space 13 includes a space bottom 11 as a building foundation and a space top 10 connected to the ground, and the space bottom 11 has at least a first part 17 that bears heavier pressure and a second part that bears lighter pressure 18;

[0034]The difference between the first force difference between the buoyancy force and pressure experienced by the second part 18 and the second force difference between the buoyancy force and pressure force experienced by the first part 17 is greater than the maximum bending resistance at point B of the junction of the two force;

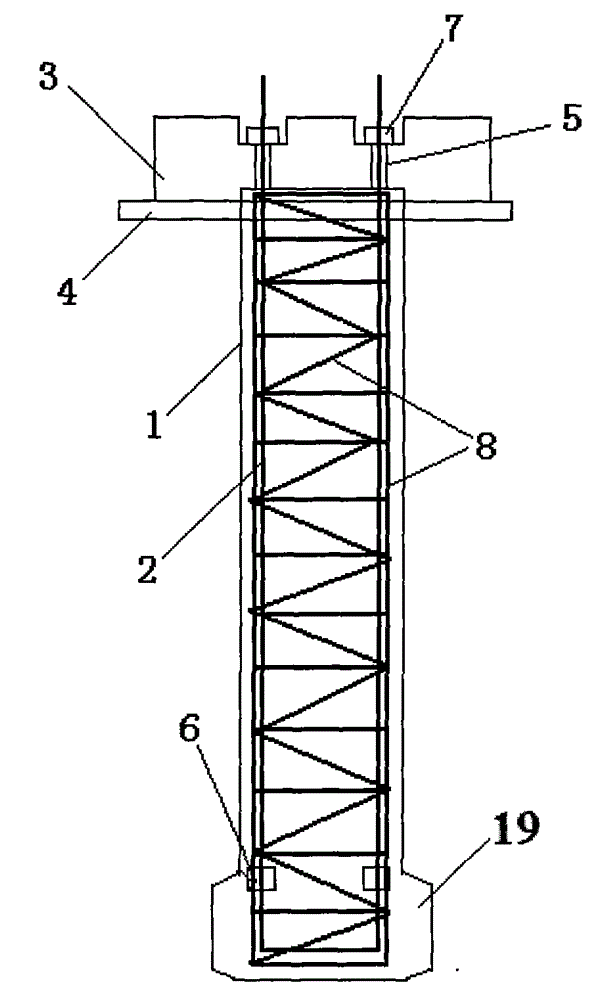

[0035] Below the first part 17, a first pile group 13 for supporting and fixing the first part 17 is arranged, the first pile group can be a conventional pile group, and in the second part 18 The second pile group 16 for supporting and fixing the second part 18 ...

Embodiment 2

[0042] An underground space building structure adopting the construction method of Embodiment 1, comprising:

[0043] As the space bottom 11 of the building foundation and the space top 10 connected to the ground, the space top 10 has at least a first part 17 that bears a heavier pressure and a second part 18 that bears a lighter pressure; wherein the second part is subjected to The difference between the first force difference between the buoyancy force and the pressure force and the second force difference between the buoyancy force and the pressure force experienced by the first part is greater than the maximum bending resistance force of the junction of the two parts;

[0044] It also includes a first pile group 13 and a second pile group 16, which are respectively arranged vertically below the first part 17 and the second part 18, and are respectively connected to the first part 17 and the second part. 18 is supported and fixed, so as to ensure that the force difference b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com