End unbonded unequal strength reinforced concrete beams

A reinforced concrete beam, non-bonded technology, applied in the field of reinforced concrete beams and high-strength reinforced concrete beams, can solve problems such as large residual deformation of longitudinal bars, improve ductility and energy dissipation capacity, be economical, and reduce residual deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

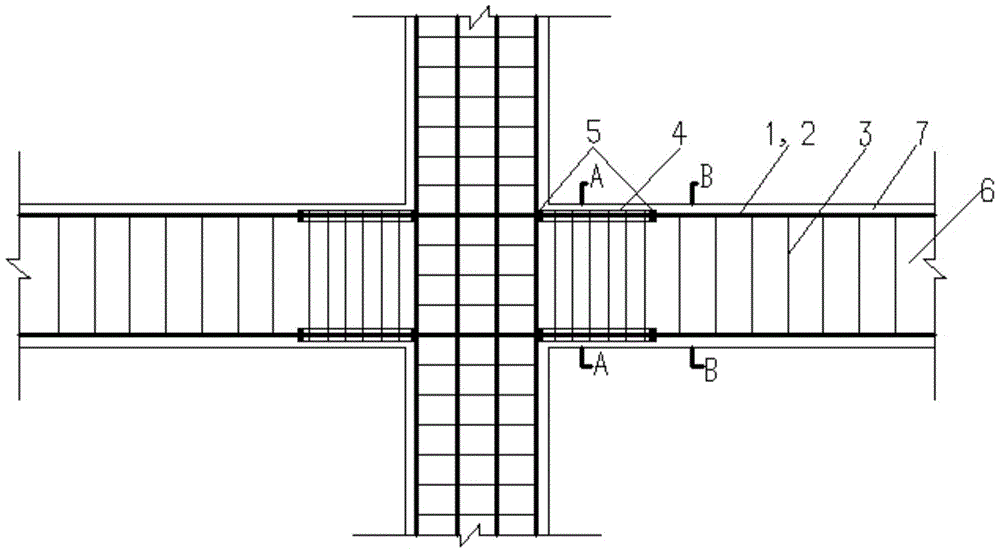

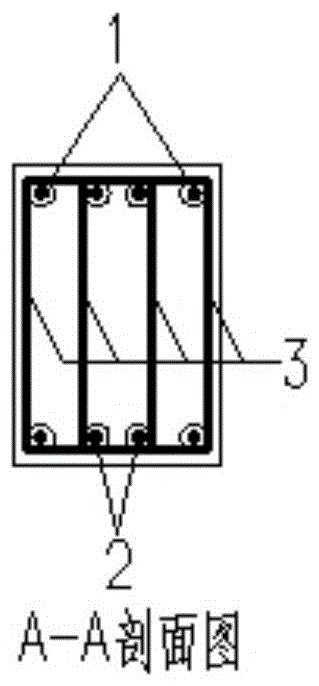

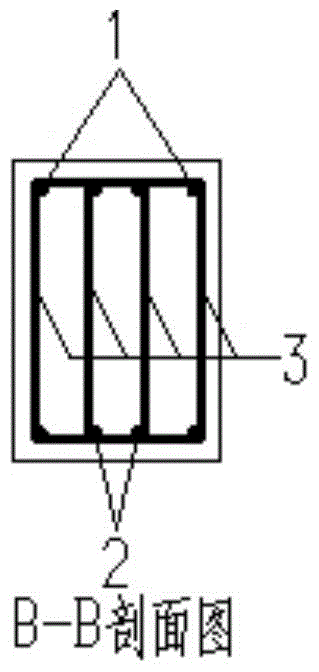

Image

Examples

Embodiment Construction

[0036] 1. Cut the bellows and fill the foam plug.

[0037] The maximum diameter of the longitudinal reinforcement used is d 0 , choose a diameter of 1.5d 0 The bellows, the bellows according to the effective height h of the beam section 0 Make a cut. Make a diameter of 1.5d 0 Cylindrical foam plugs with a height of 1 / 10h 0 , A round hole with a diameter smaller than that of the longitudinal rib is cut out in the center of the foam plug. Secure the foam plugs to both ends of the bellows with 914 adhesive.

[0038] 2. Fix the bellows filled at both ends to the ends of the longitudinal ribs.

[0039] The longitudinal reinforcement passes through the foam plug hole on the corrugated pipe, and the thin steel wire penetrates the corrugated pipe and fixes it with the steel bar.

[0040] 3. Binding of steel cage

[0041] The binding of the reinforcement cage must be carried out in strict accordance with the relevant specifications and drawings.

[0042] 4. Beam formwork and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com