Overall installing device and installing method for extra-large shield launching hole door sealing steel ring

It is a technology of integral installation and starting hole, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve the problems of insufficient upward construction and extension space for hoisting equipment, low installation efficiency, and difficult installation and operation, so as to avoid repetition The effect of splicing and disassembling operation, material saving and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

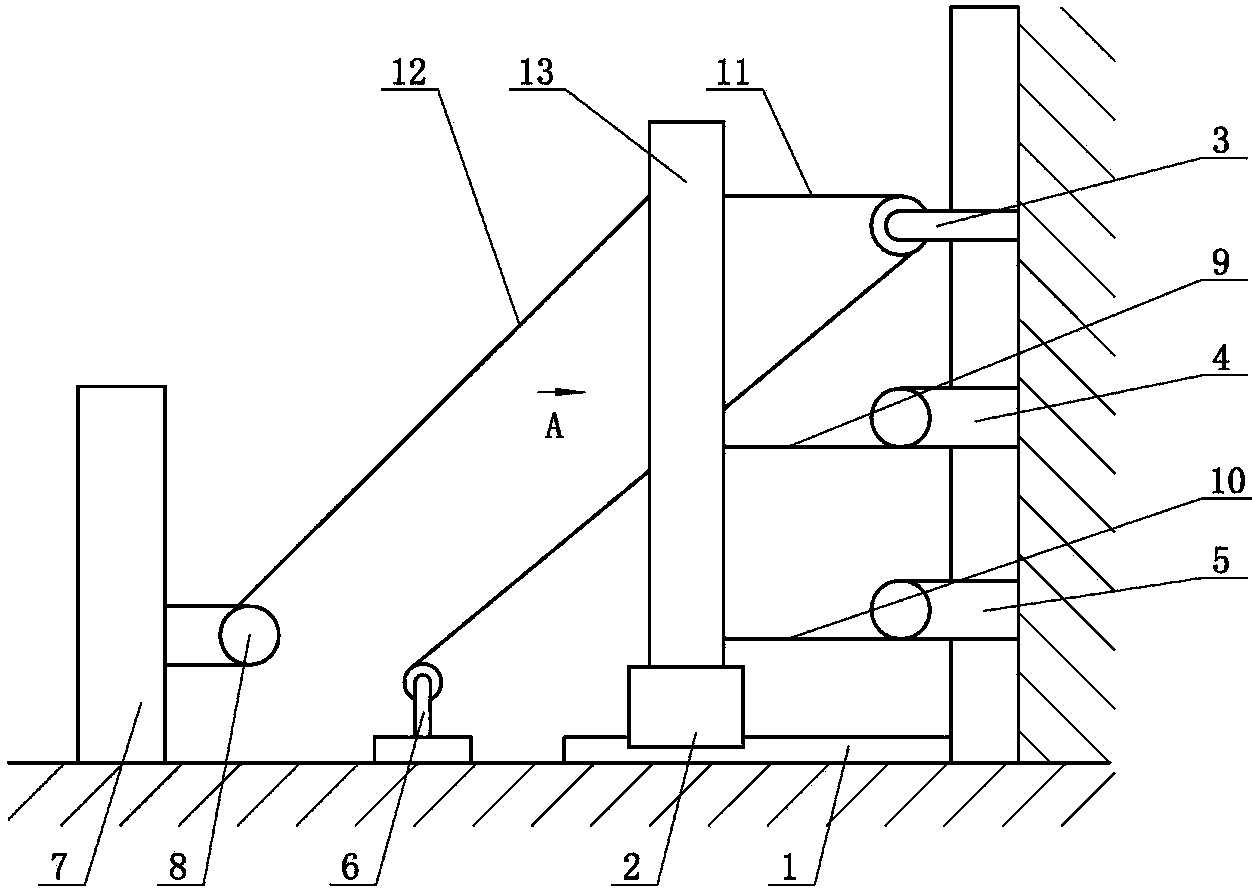

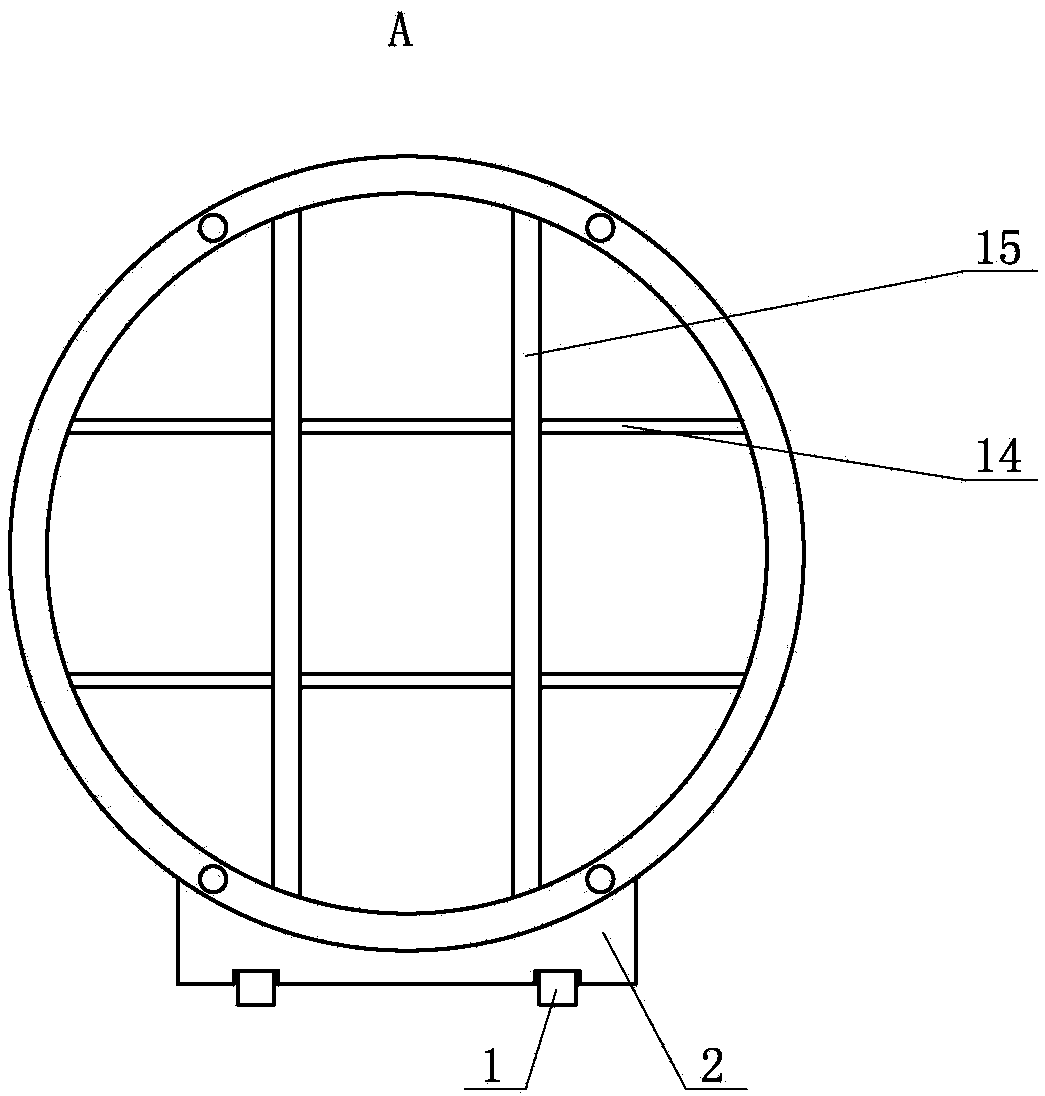

[0010] The overall installation device for the sealing steel ring of the starting portal of the super-large shield tunnel, such as figure 1 As shown, it includes slide rail 1. Slide rail 1 is perpendicular to the originating portal of the super-large shield machine. Slide rail 1 is installed on the ground outside the super-large shield tunneling portal. Vertically place the sealing steel ring 13 of the starting portal of the super-large shield tunneling machine, and ensure that the sealing steel ring of the starting portal of the super-large shield tunneling machine is The lower part of the 13 moves in a straight line to ensure the accuracy of the moving track and improve the stability of the sealing steel ring 13 of the opening door of the super-large shield tunnel. The upper, middle, and lower parts of the starting portal of the super-large shield machine are respectively provided with steering wheels 3, the first chain hoist 4, and the second chain hoist 5, and the slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com