Plunger pump and carbon dioxide injection device for oil field

A carbon dioxide, plunger pump technology, applied in the components, pumps, pump elements, etc. of the pumping device for elastic fluid, to achieve the effect of stable pressure and rapid automatic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

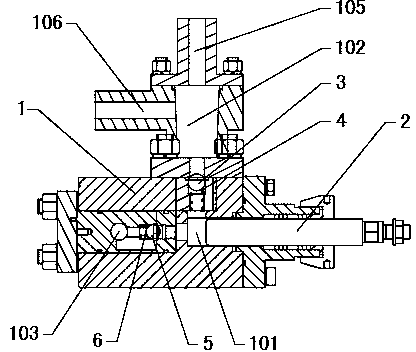

[0035] refer to figure 1The plunger pump includes a pump body 1 and a plunger 2. The pump body 1 is L-shaped. The pump body 1 is respectively provided with a pump chamber 101, a liquid inlet chamber 102 and a liquid discharge chamber 103. The liquid inlet chamber 102 is located in the vertical position of the pump body 1. At the upper end of the straight part, the pump chamber 101 is located in the L-shaped bending part of the pump body 1, the liquid discharge chamber 103 is located in the horizontal part of the pump body 1, the plunger 2 is movably arranged in the pump chamber 101, and the liquid inlet chamber 102 is connected to the pump chamber 101. In the upper part, the liquid discharge chamber 103 communicates with the side of the pump chamber 101, and the upper part of the liquid inlet chamber 102 communicates with the outside of the pump body 1 through the exhaust passage 105. The vaporized medium in the pipeline and the vaporized medium in the pump chamber 101 will aut...

Embodiment 2

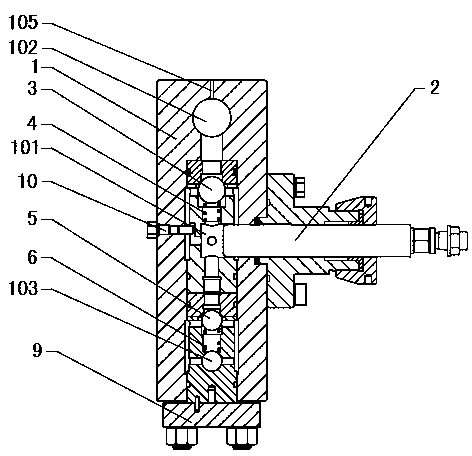

[0041] refer to figure 2 The plunger pump includes a pump body 1 and a plunger 2. The pump body 1 is a straight-through type. The pump body 1 is provided with a liquid inlet chamber 102, a pump chamber 101 and a liquid discharge chamber 103 from top to bottom. The lower end of the pump body 1 is sealed. A flange 9 is fixed, and the plunger 2 is movable in the pump chamber 101. An exhaust passage 105 is provided at the upper end of the pump body 1. The inner end of the exhaust passage 105 communicates with the upper part of the liquid inlet chamber 102, and the outer end of the exhaust passage 105 communicates. Outside the pump body 1, after the medium in the pump chamber 101 vaporizes, the gas has a light specific gravity and rises automatically. It enters the top of the liquid inlet chamber 102 from the pump chamber 101 and is discharged through the exhaust channel 105. The exhaust is smooth and the liquid inlet chamber 102 The pressure in the medium storage tank is equal to...

Embodiment 3

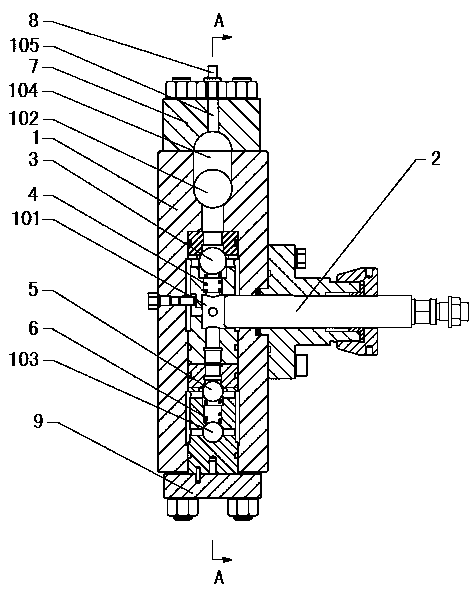

[0043] refer to Figure 3-4 The difference between this embodiment and Embodiment 2 is that a liquid inlet chamber pressure plate 7 is fixed on the upper end of the pump body 1, an air collection chamber 104 is opened between the liquid inlet chamber pressure plate 7 and the pump body 1, and the liquid inlet chamber 102 communicates with the collection chamber. The lower part of the air chamber 104, the exhaust channel 105 is opened on the pressure plate 7 of the liquid inlet chamber, and communicates with the upper part of the gas collection chamber 104, the gas generated in the pump chamber 101 rises into the liquid inlet chamber 102 and continues to rise, and the gas will be concentrated On the upper part of the gas collection chamber 104, the exhaust channel 105 can effectively prevent the liquid medium in the liquid inlet chamber 102 from being discharged with the gas when discharging the gas, realize gas-liquid separation, improve the exhaust performance and the working e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com