Heat exchanging device based on phase-change heat storage material and packaging method thereof

A technology of phase change heat storage material and heat exchange device, which is applied in the direction of heat storage equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problems of short service life, no consideration of expansion and crack damage, etc., and achieve long service life , Simple structure, prevent the shell from bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

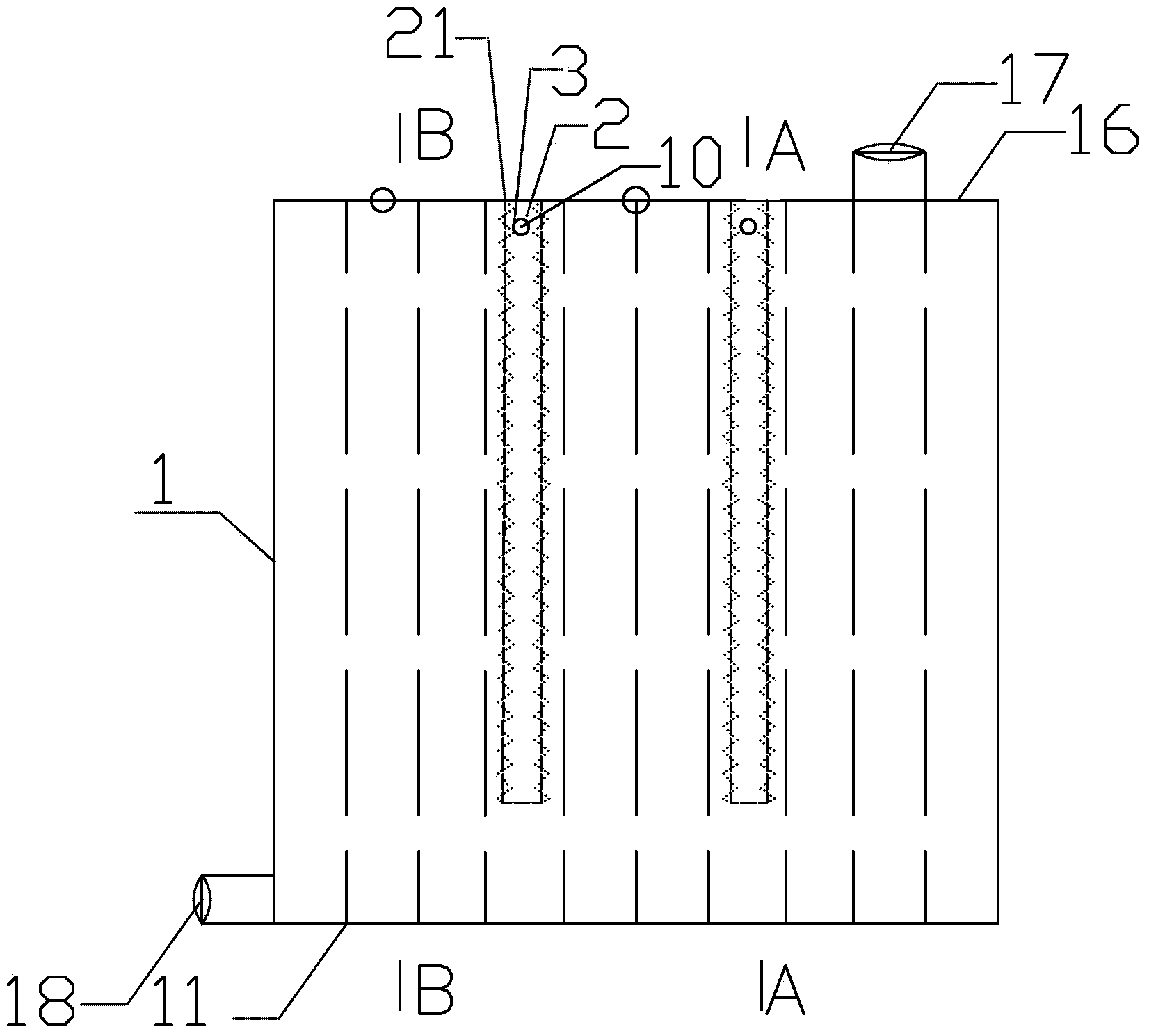

[0023] Specific implementation mode one: as figure 1 As shown, a heat exchange device based on a phase-change heat storage material includes a closed casing 1 for accommodating the phase-change heat storage material, and the casing surface of the casing 1 is arranged toward the inside of the casing. There is at least one inwardly concave expansion partition 2 for expansion and deformation, and the side wall or part of the side wall of the expansion partition 2 is made of a flexible film 3 . The upper side of the expansion partition 2 communicates with the atmosphere, that is, the expansion partition 2 is a depression that is added from the upper surface of the housing to the inside of the housing, and only the upper part of this depression communicates with the atmosphere, that is, from the front view ( figure 1 ) direction, the shell has a "concave" shape structure, and the lower part is connected to inject phase change heat storage material.

specific Embodiment approach 2

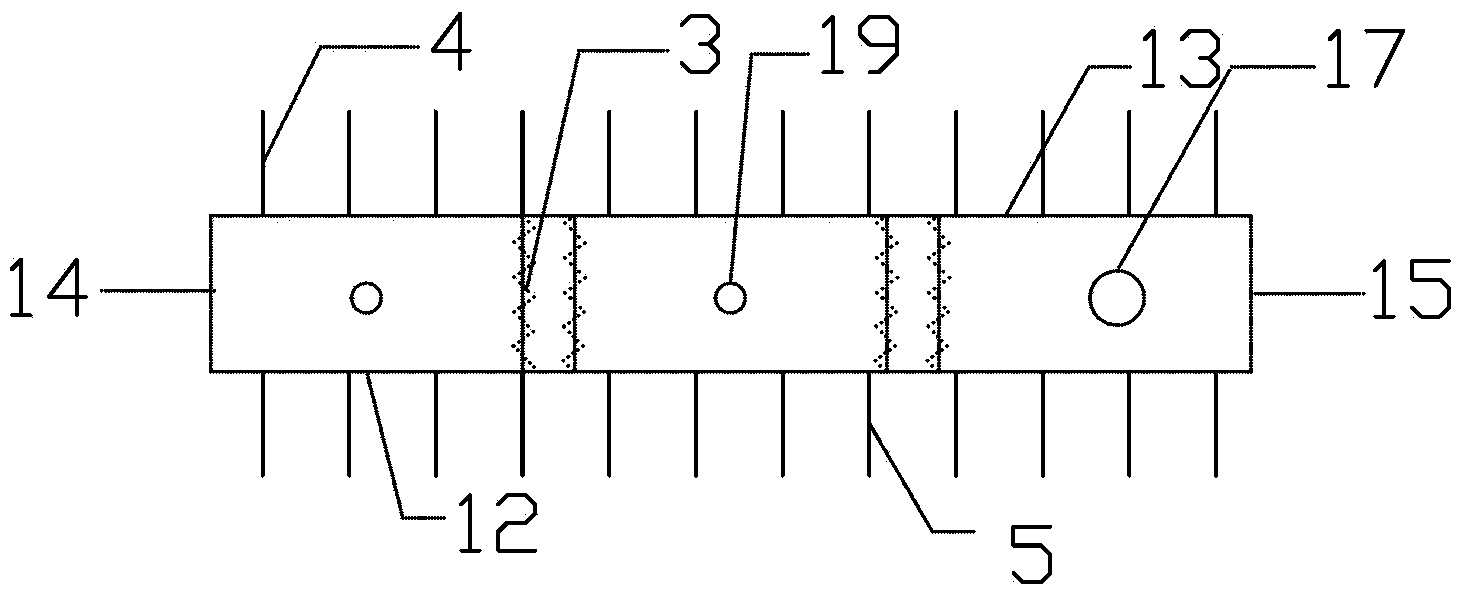

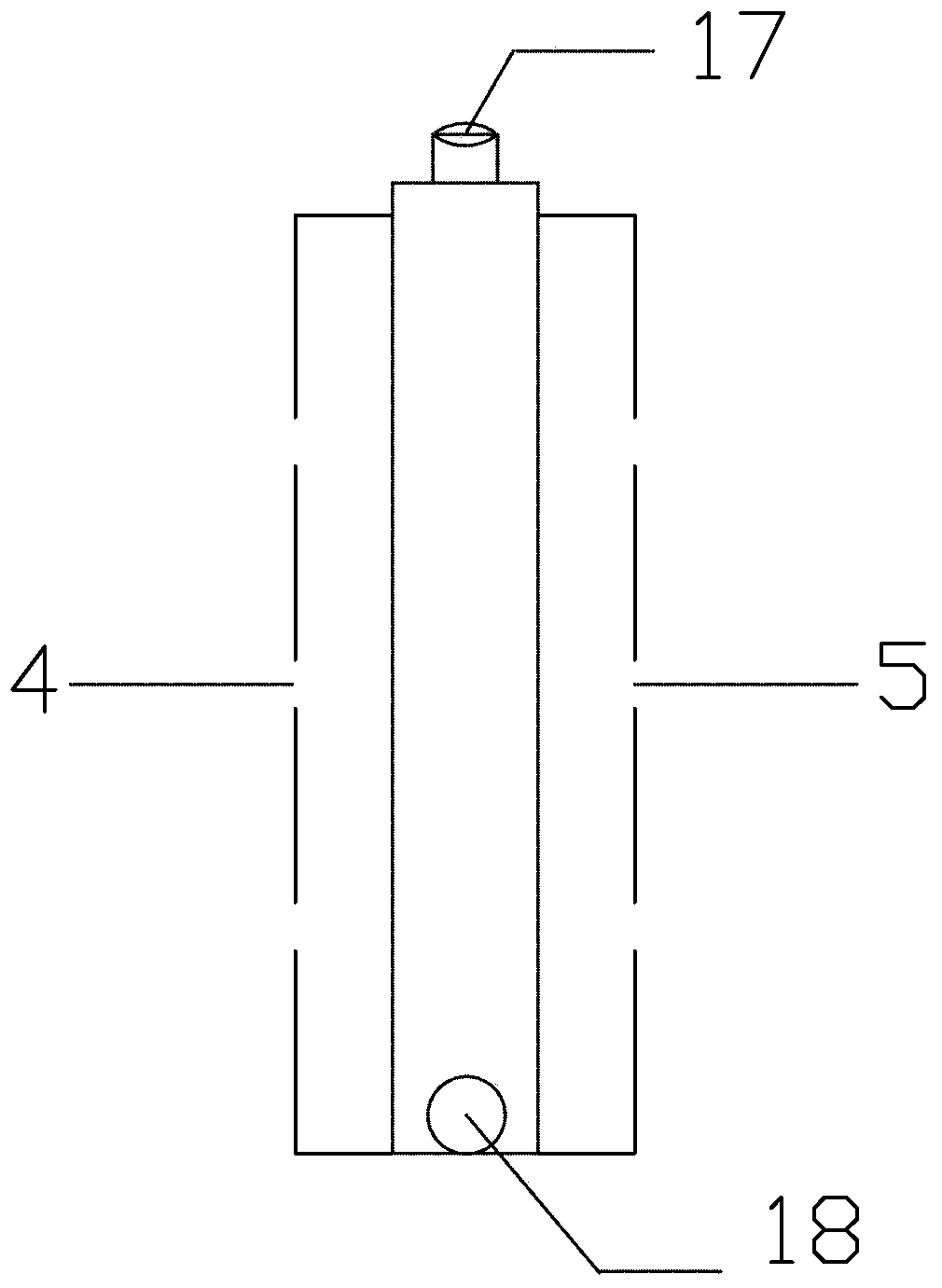

[0024] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: if figure 2 As shown, the housing 1 is a closed enclosure surrounded by a bottom housing 11, a front housing 12, a rear housing 13, a left side housing 14, a right side housing 15 and an upper cover housing 16. shell; such as figure 1 As shown, the expansion partition 2 is a depression provided in the direction from the upper cover shell 16 to the bottom shell 11 . The expansion partition 2 represents that the upper cover shell 16 is divided into a space that communicates with the atmosphere, and the side wall of the expansion partition 2 extending into the shell can be inlaid in the middle by a metal plate made of the same material as the shell 1. The flexible film 3 is made, and the flexible film 3 can be a flat diaphragm or a pleated diaphragm.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment two is that a dustproof sealing cover 21 is provided above the expansion partition 2, and the dustproof sealing cover 21 and the upper cover shell 16 are in the same level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com